Soft measurement method for on-line detection of components in special rectification process

A rectification process and soft-sensing technology, applied in the field of rectification process control, can solve problems such as measurement lag, too many controlled quantities, and difficult parameter adjustment of the model, so as to improve stability, remove the influence of algorithm stability, and improve automatic The effect of adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

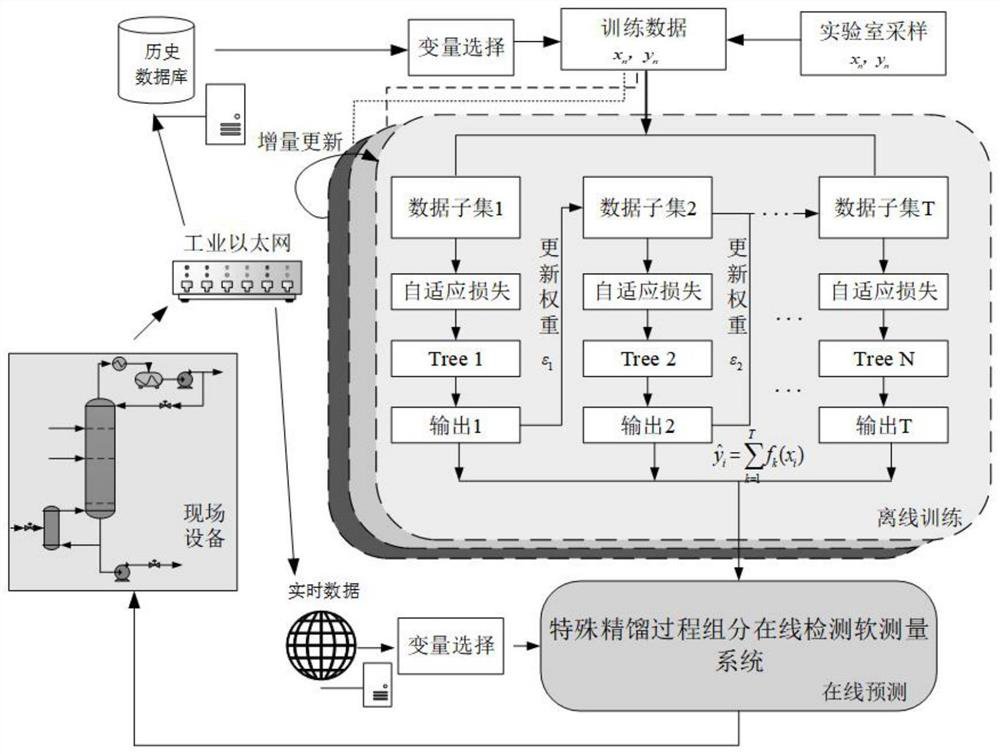

[0030] according to figure 1 , 2 As shown, this embodiment provides a soft sensor method for on-line detection of components in a special rectification process, including the following steps:

[0031] Step 1. After collecting historical data and normalizing it, the principal variable is extracted through principal component analysis, and the principal variable is used as input to establish a random forest model to obtain the variable importance index, and the variable value with a large random forest importance index is selected as Input variables into the soft sensor model;

[0032] Among them, the obtained principal variable is decomposed into eigenvalues. The eigenvalue decomposition method is to randomly select the eigenvalues to split the spanning tree, and count the sum of the Gini index decline degrees of the branch nodes in each tree to obtain the importance of the features, and randomly The forest uses a parallel bagging method. After the eigenvalues are decompo...

Embodiment 2

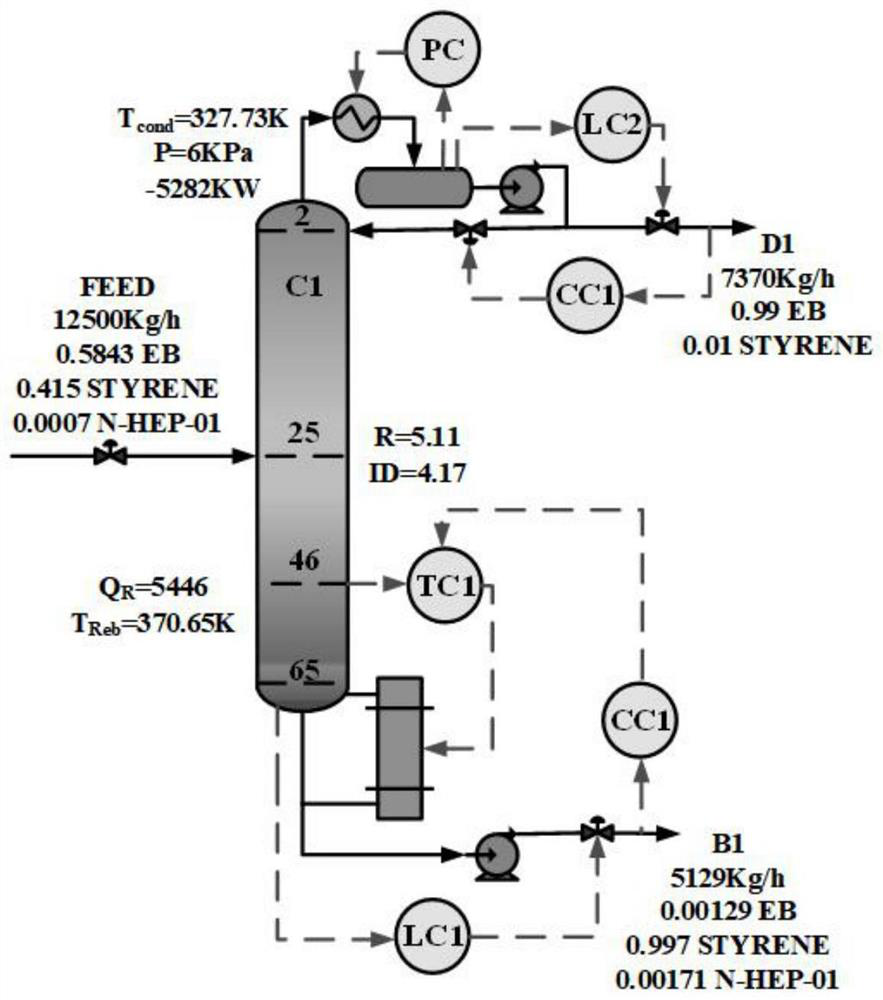

[0042] In this example, a single-column rectification process for the industrial production of ethylbenzene and styrene is constructed through the chemical engineering simulation software Aspen Plus and Aspen dynamic. The process flow is as attached to the description. figure 2As shown, the rectification is 12500Kg / h, and the rectification components are: 58.43wt% ethylbenzene, 41.5wt% styrene and a small amount of tar. The rectifying tower overhead product is the ethylbenzene of 99wt%, the styrene of 99.7wt%, wherein

[0043] (1) The feed flow rate is adjusted by the flow controller;

[0044] (2) The top reflux tank and the liquid level at the bottom of the tower are adjusted by flow controllers LC1 and LC2;

[0045] (3) The temperature of the 46th tray is regulated by the temperature controller TC1;

[0046] (4) the purity of the overhead product ethylbenzene is regulated by regulating the overhead reflux flow;

[0047] (5) the purity of the product styrene at the bottom...

Embodiment 3

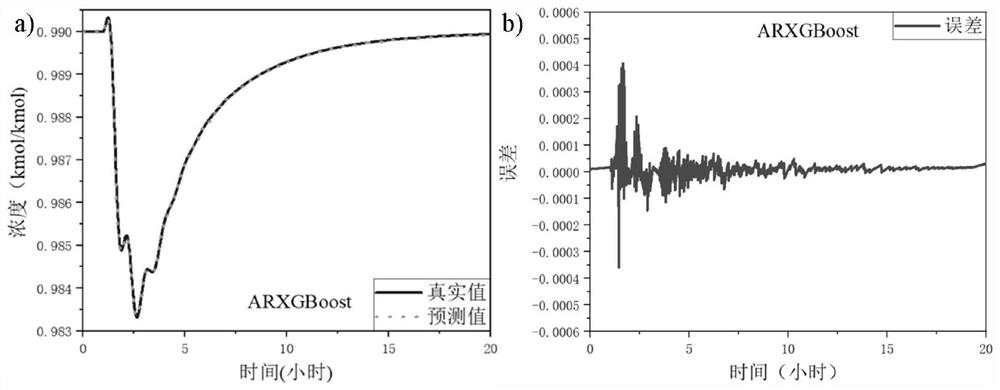

[0052] In this example, a THF / ethanol / water three-tower pressure-swing rectification process is constructed through the chemical engineering simulation software Aspen Plus and Aspen dynamic, and the flow chart is as attached to the description Figure 4 As shown, in order to establish a soft-sensing model to predict the composition of the bottom product, a soft-sensing model is established with the water purity of the bottom product of pressure swing rectification column 1 as the object. Regardless of the influence of the variables of the latter two towers on it, a total of 400 hours of dynamic data were simulated, and the sampling interval was 36s. Select 20 hours of it for testing, evaluate the performance of the model, and add random white noise to the data. According to the evaluation indexes predicted by six different algorithms, the determination coefficient values of all models are above 0.9, which proves that the soft sensor model of the bottom components of the dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com