Line layout method based on assembly type line pipe fittings

A line layout and assembly technology, which is applied in the direction of electrical components, cable installation, cable installation devices, etc., can solve the problems of relatively high professional requirements for bending pipes, smaller diameters of pipe bends, and increased difficulty of bending pipes, etc. , to achieve the effect of improving construction efficiency, reducing construction strength and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

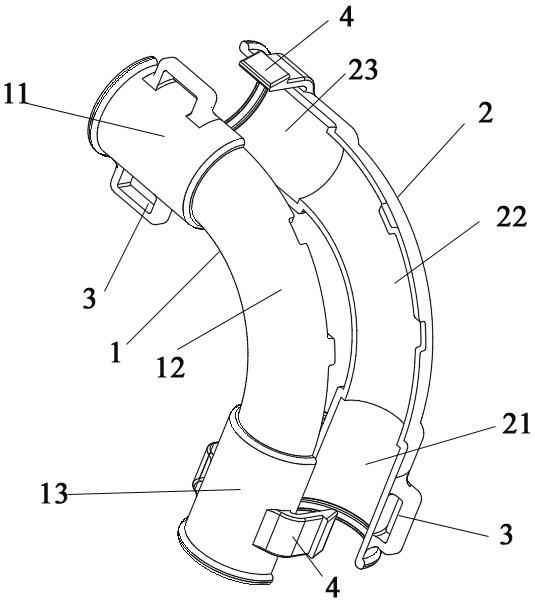

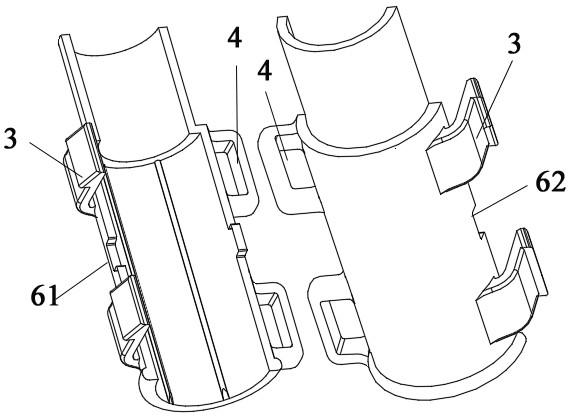

[0027] The socket conduit includes a first connecting piece 1 and a second connecting piece 2, the first connecting piece 1 and the second connecting piece 2 have the same structure, as figure 1 In the structure shown, the first connecting piece 1 is integrally formed, including the first elbow portion 11, the first connecting pipe portion 12 and the first bent tail portion 13, and the second connecting piece 2 is integrally formed, including the second elbow portion 21, The second connecting pipe part 22 and the second bent tail part 23, two snap rings 3 are arranged on the outer sides of the first bent tail part 11, two plug-ins 4 are arranged on the outer sides of the first bent tail part 13, and the second bent tail part 13 is provided with two snap rings 3 on both sides. Two snap rings 3 are provided on the outer sides of the head 21 for inserting the inserter 4 of the first bent tail 13, and two inserts 4 are arranged on the outer sides of the second bent tail 23 for inse...

Embodiment 2

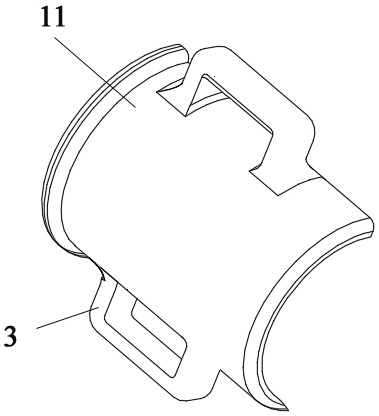

[0029] The connecting pipe includes a first elbow 11, a first elbow 13, a second elbow 21, a second elbow 23 and a first connecting pipe 12, the first connecting pipe 12 is integrally formed, as figure 2 As shown, two snap rings 3 are provided on both sides of the first elbow 11, two inserts 4 are provided on both sides of the first elbow 13, and two outer sides of the second elbow 21 are provided. Two snap rings 3 are provided on the outside of the second bent tail 23, the first bent head 11 and the second bent tail 23 are snapped together to form a buckle cavity at the head end, and the second bent head 21 is connected to the first bent tail 23. The tail part 13 is clamped to form a terminal buckle cavity, and the head-end buckle cavity and the end buckle cavity are respectively buckled at both ends of the connecting pipe body.

Embodiment 3

[0031] The receiving pipeline includes a first connecting piece 1 and a second connecting piece 2. The first connecting piece 1 is integrally formed, including a first elbow portion 11, a first connecting pipe portion 12 and a first bent tail portion 13. The second connecting piece 2 is integrally formed. Forming, including the second elbow part 21, the second connecting pipe part 22 and the second bent tail part 23, the outer two sides of the first elbow part 11 are provided with a snap ring 3 and a plug-in 4, the first bent tail part 13 A plug-in 4 and a snap ring 3 are provided on the outside, and a snap ring 3 and a plug-in 4 are provided on both sides of the second elbow 21 for inserting the plug-in 4 and the snap ring 3 of the first elbow 11 There are two inserts 4 on both sides of the outside of the second curved tail 23, which are used to insert the snap ring 3 and the plug 4 of the first curved tail 13, and the first connecting pipe part 12 and the second connecting pi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap