Wall surface polishing device for building construction

A technology for building construction and grinding discs, which is used in grinding/polishing safety devices, machine tools suitable for grinding workpiece planes, grinding machines, etc., and can solve the problems of high physical requirements for workers, low operating efficiency, and uneven grinding surfaces. Achieve the effect of ensuring dust removal effect, high grinding efficiency and large grinding area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

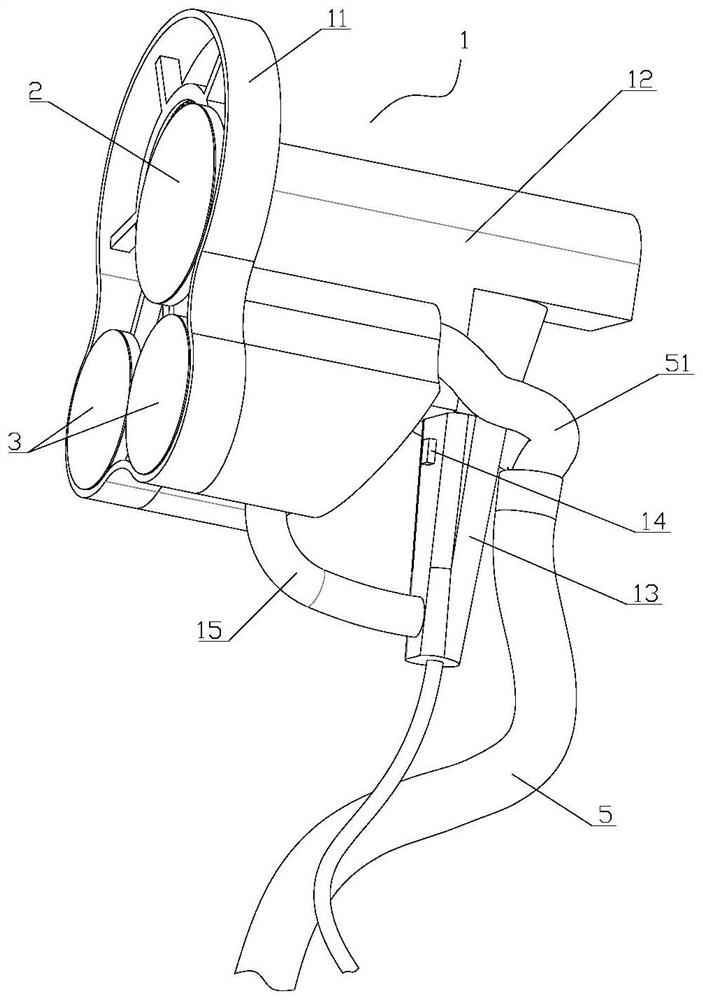

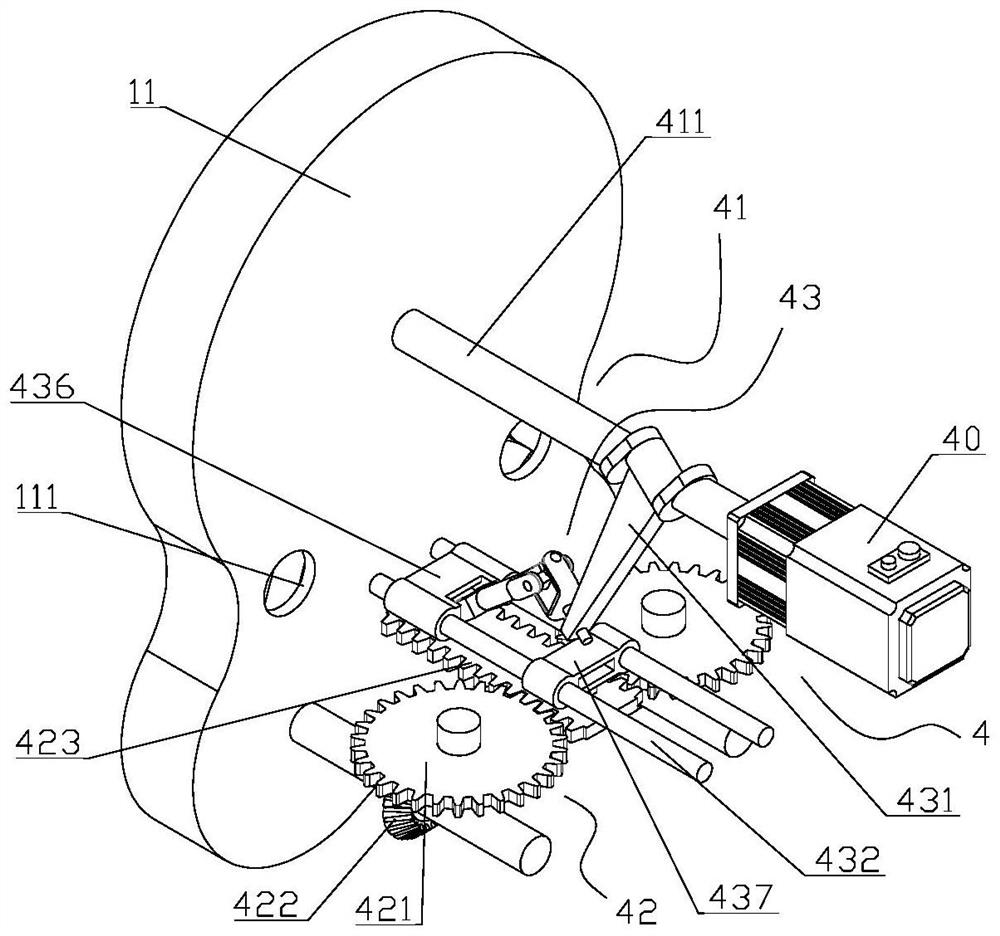

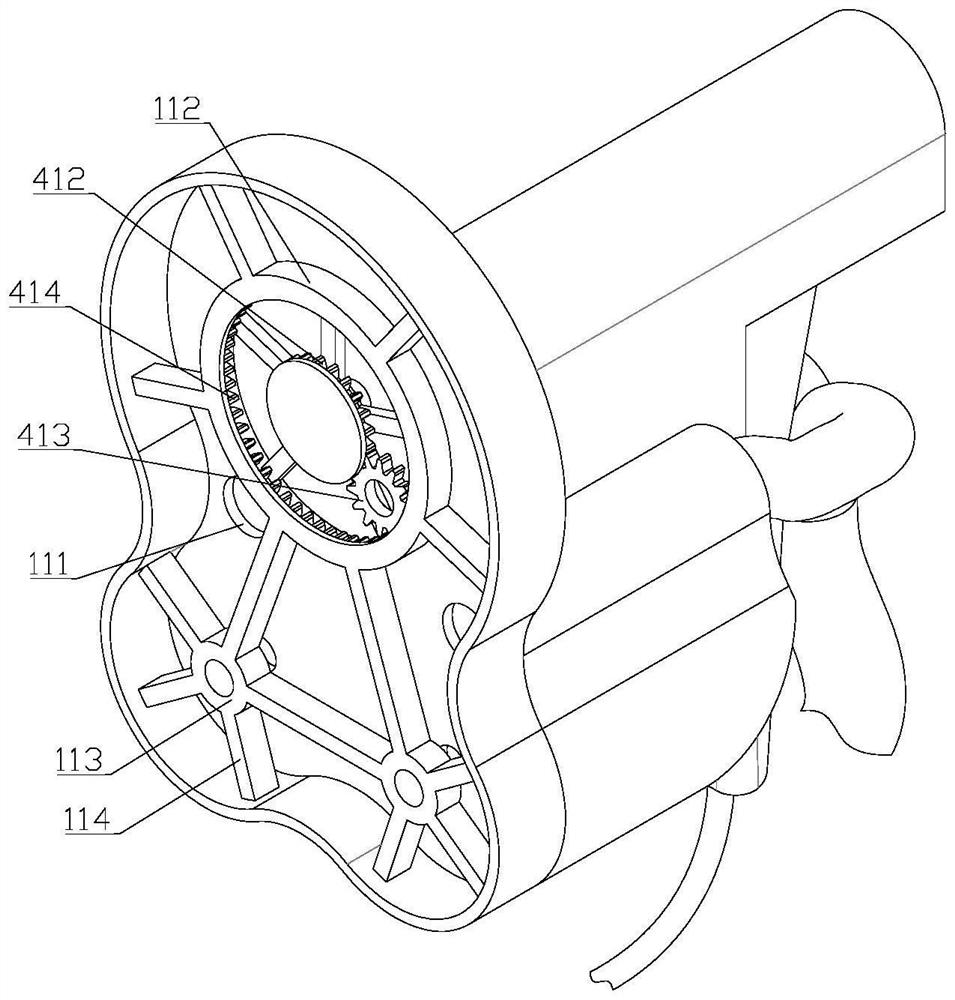

[0032] see Figure 1 to Figure 8, the embodiment of the present invention provides a wall grinding device for building construction, which includes a housing 1, a grinding drive unit 4 arranged in the housing 1, a first grinding disc 2 and a second grinding disc controlled by the grinding drive unit 4, respectively. Grinding disc 3, and a dust suction pipe 5 arranged on the shell 1;

[0033] The grinding drive unit 4 includes a first driving module 41 that controls the rotation of the first grinding disc 2, a second driving module 42 that controls the rotation of the second grinding disc 2, and controls the grinding of the first driving module 41 and / or the second driving module 42. Motor 40.

[0034] Preferably, the grinding surface of the first grinding disc 2 is coplanar with the grinding surface of the second grinding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com