Processing device

A technology for processing devices and workpieces, which is applied to fine working devices, stone processing equipment, grinding drive devices, etc., and can solve problems such as the inability to accurately detect and control the cutting depth of cutting tools into workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

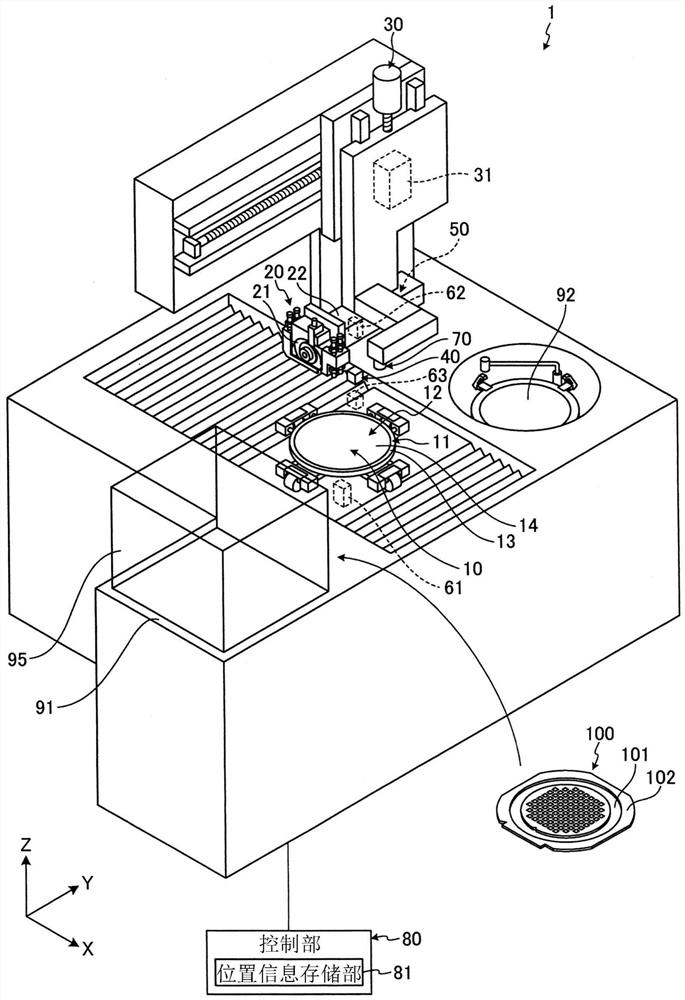

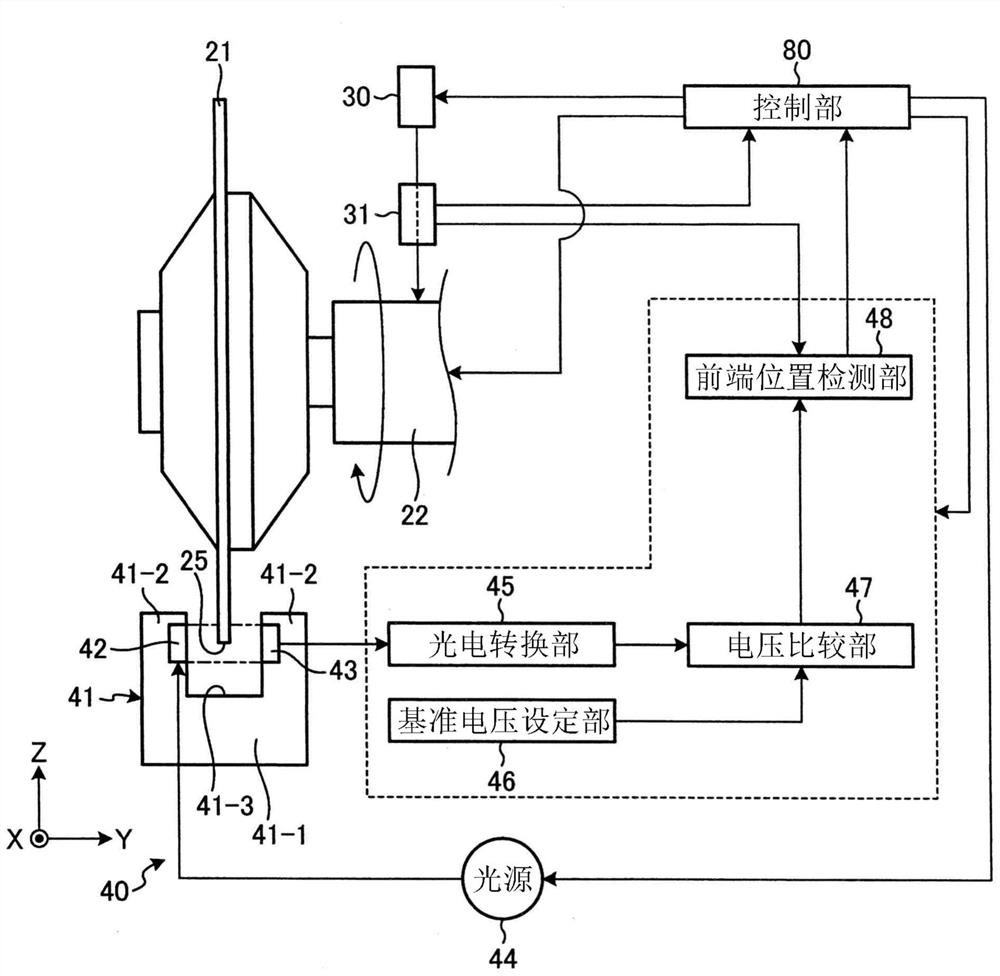

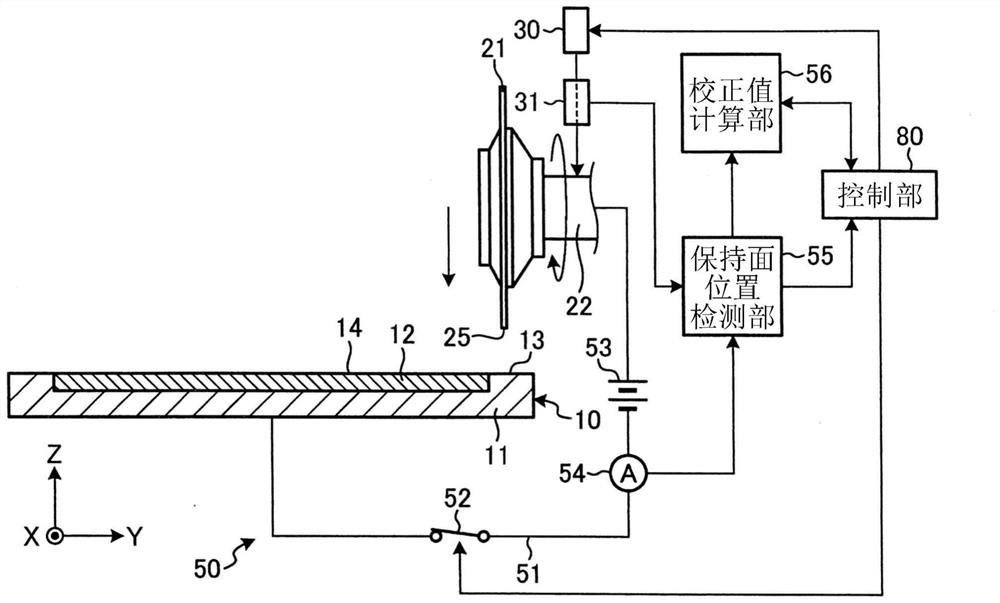

[0021] The processing apparatus 1 of Embodiment 1 of this invention is demonstrated based on drawing. figure 1 It is a perspective view showing a configuration example of the processing apparatus 1 according to the first embodiment. figure 2 is showing figure 1 A cross-sectional view of a structural example of the setting unit 40 . image 3 is showing figure 1 A cross-sectional view of a structural example of the correction unit 50. Figure 4 is showing figure 1 The sectional view of an example of the positional relationship of the holding table 10, the cutting unit 20, and the installation unit 40 of FIG.

[0022] Such as figure 1 As shown, the processing device 1 has a holding table 10 , a cutting unit 20 , a Z feed unit 30 , a setting unit 40 , a calibration unit 50 , temperature measuring devices 61 , 62 , and 63 , an imaging unit 70 , and a control unit 80 .

[0023] The workpiece 100 to be processed by the processing apparatus 1 according to Embodiment 1 is, for e...

Embodiment approach 2

[0070] The processing apparatus 1 according to Embodiment 2 of the present invention will be described. In the processing device 1 according to the second embodiment, the imaging unit 70 which moves integrally with the cutting unit 20 substantially implements the function of detecting the holding surface position Z2 performed by the calibration unit 50 in the first embodiment. Specifically, in Embodiment 2, the imaging unit 70 obtains from the Z-direction position detection unit 31 the upper surface 13 of the housing 11 of the holding table 10 that is on the same plane as the holding surface 14 to focus the imaging unit 70 . The position of the cutting unit 20 in the Z direction is obtained, and the obtained position of the cutting unit 20 in the Z direction is output to the control unit 80 .

[0071] Here, by considering the position difference between the cutting unit 20 and the imaging unit 70 in the Z direction, the height of the imaging unit 70 in the Z direction can be c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com