Grabbing mechanism for chip processing

A grasping mechanism and chip technology, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems of easily damaged chip pins, and achieve the effect of avoiding breakage and bending, protecting the appearance, and limiting the use of the scene.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

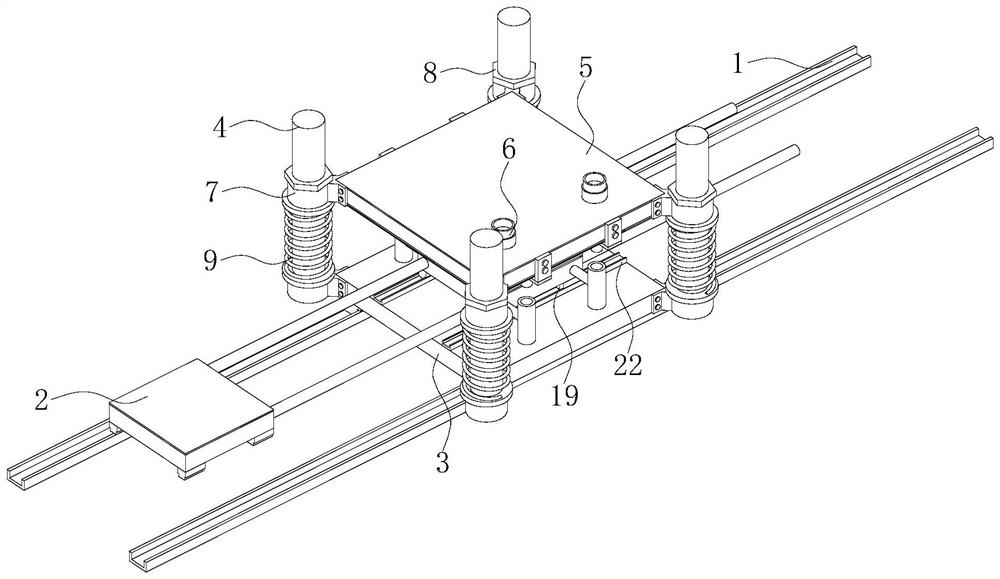

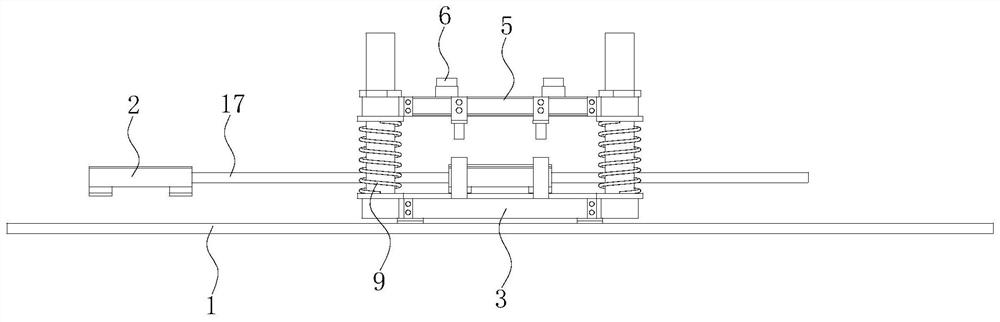

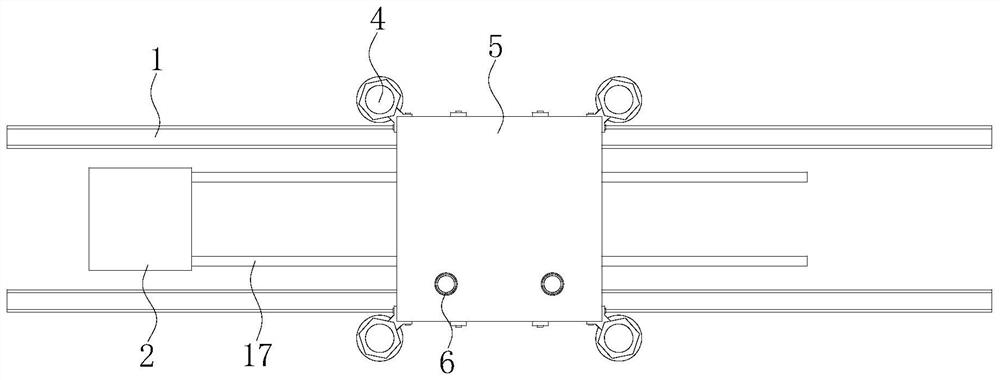

[0023] Such as Figure 1-7 As shown, a grabbing mechanism for chip processing includes two slide rails 1 and a placement mechanism 2, a base 3 is arranged between the two slide rails 1 and the placement mechanism 2, and slide rails are fixedly installed at the four corners of the base 3. Rod 4, the placement mechanism 2 is slidingly connected with the upper surface of the base 3, the top of the base 3 is located on the placement mechanism 2 and is provided with an air chamber A5, the inside of the air chamber A5 is a hollow structure, and the bottom end of the air chamber A5 is open. There are two air pipes 6 communicating with the inside of the chamber A5. The air pipes 6 are responsible for connecting the air pump and the control valve. The four corners of the air chamber A5 are fixed with collars 7. The outside of the slide rod 4 is a smooth cylindrical structure. The upper end of the slide rod 4 is threaded, and the four slide rods 4 respectively pass through the four coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com