Preparation method for high-hardness water paint applied to vacuum-cup surface

A water-based coating with high hardness technology, applied in the direction of coating, etc., can solve the problems of low hardness, easy scratch of surface coating, low mechanical strength of organic paint coating, etc., so as to avoid coating wear and protect the appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

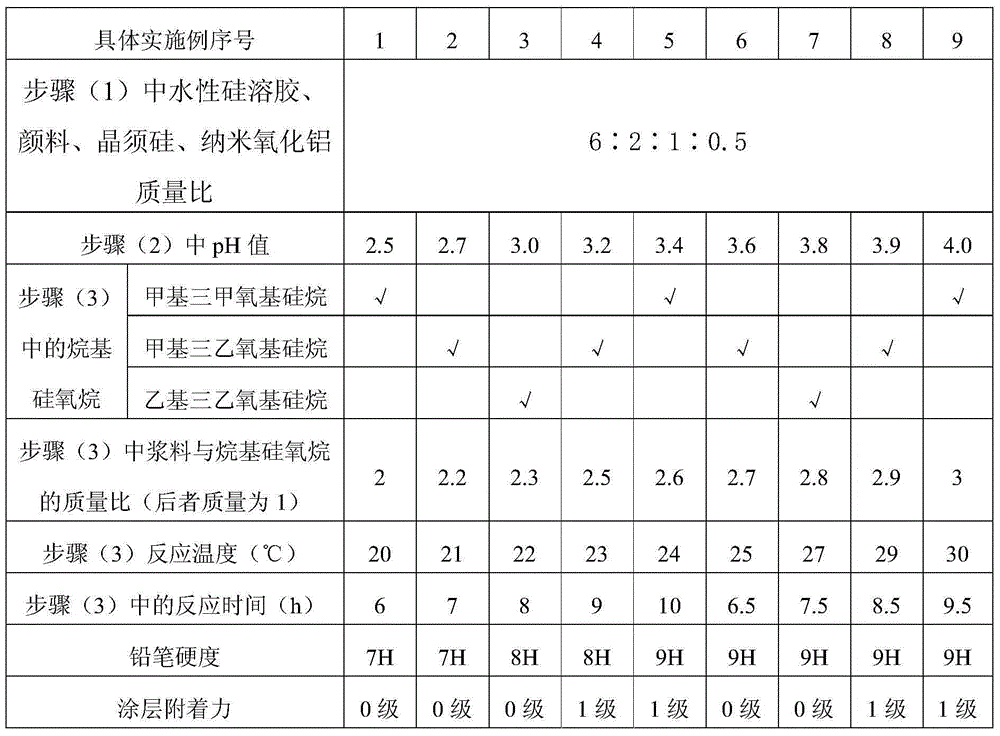

Examples

Embodiment Construction

[0017] The thermos cup is generally made of 316L stainless steel. Stainless steel will turn yellow when it is treated at a temperature above 170°C. Nano-composite coatings are formed after the reaction of alkyl silanes, which can form a high-hardness coating at a lower heat treatment temperature (160 ° C), so that the stainless steel thermos cup can obtain high hardness and wear resistance, and at the same time it has good adhesion. , to meet the protective performance of the surface of the thermos cup.

[0018] In the present invention, each raw material used is the prior art, or is commercially available, or can be obtained by self-preparation through common technical means, and those skilled in the art have a very clear understanding of this.

[0019] The preparation method for the high-hardness water-based paint on the surface of the thermos cup of the present invention comprises the following steps:

[0020] (1) Under the stirring condition of 800r / min, mix water-based s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com