Flexible package lithium cell and method of processing the same

A lithium battery and flexible packaging technology, which is applied in the field of flexible packaging lithium batteries and their processing, can solve the problems of battery short circuit, scrapping, expansion of flexible packaging lithium batteries, etc., and achieve the effect of preventing top wrinkling, ensuring safety performance, and protecting appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

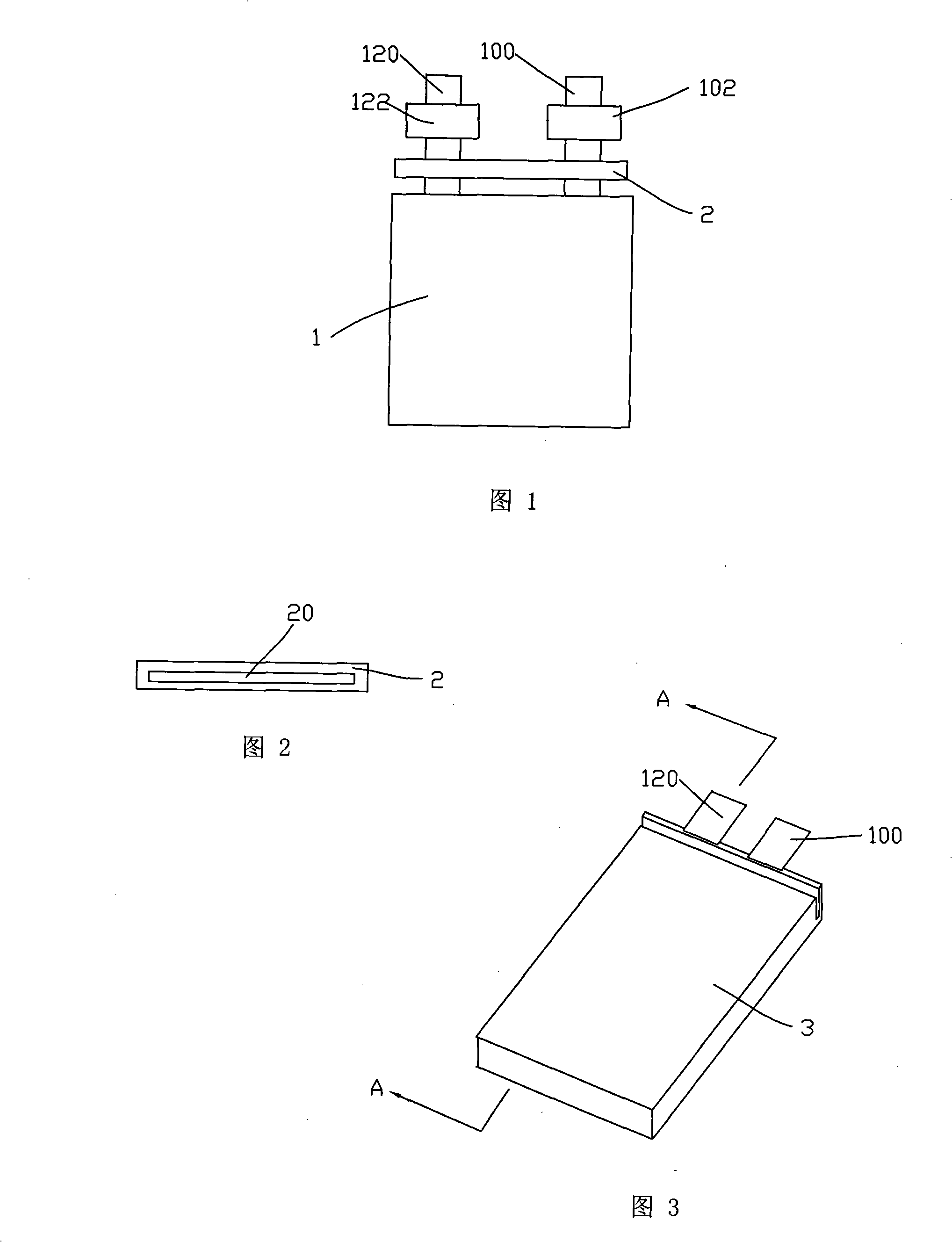

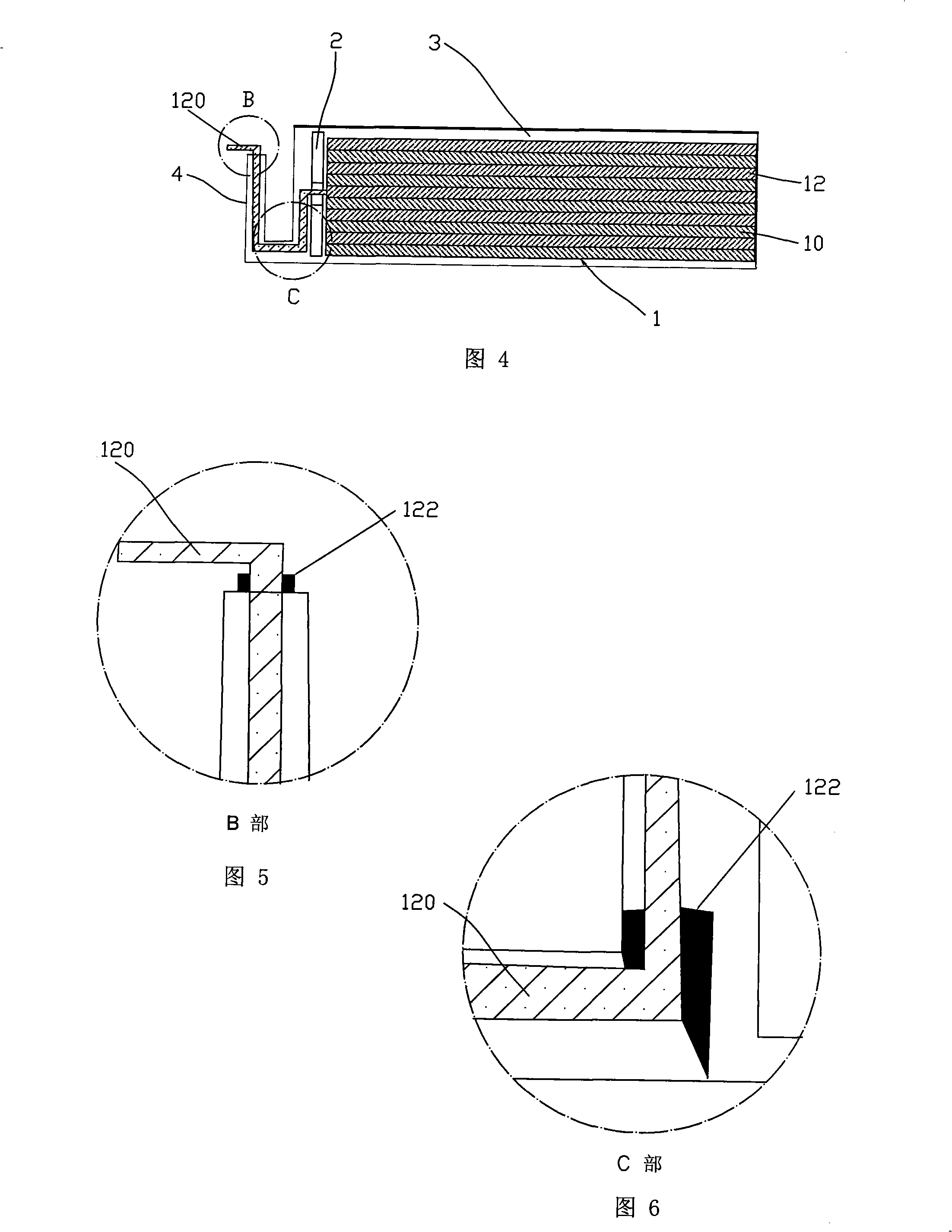

[0039] The following takes the E503048 soft package battery as an example to describe the operation process in detail. The preferred thickness of the positive tab 100 and the negative tab 120 used in the present invention is 0.1 mm. The thickness range of the spacer 2 used is 0.2-0.4 mm, preferably 0.2 mm; the length of the spacer 2 is required to be equal to the width of the winding core 1, which is 26 mm, and the width of the spacer 2 is required to be 0.05-0.05-narrower than the winding core 1 0.2 mm, preferably 0.1 mm narrower, 4.3 mm, and the width of the slot in the middle of the spacer ring is 0.1-0.3 mm, preferably 0.2 mm.

[0040] During processing, the winding core 1 is processed first; then, the spacer 2 is inserted into the positive tab 100 and the negative tab 120, and positioned between the tab glue 102, 122 and the position of the winding core 1; then, the sleeve is fitted with a spacer The winding core 1 of the ring 2 is loaded into the soft composite packagin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com