Compression assembly, compressor and air conditioner with same

A component, spring hole technology, applied in the direction of machine/engine, pump components, mechanical equipment, etc., can solve the problems of the compressor cannot run normally, the long-term reliability is poor, the pump body is stuck, etc., and achieves good long-term reliability, noise and vibration. Good, the effect of preventing the spring hole from popping out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

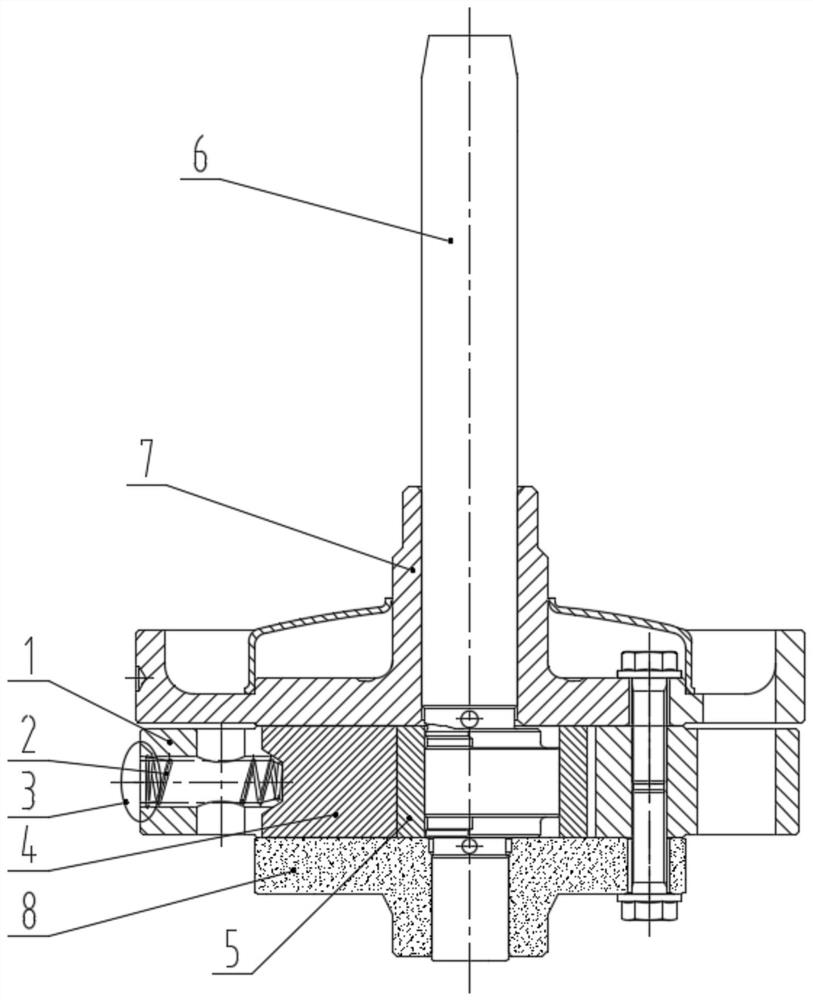

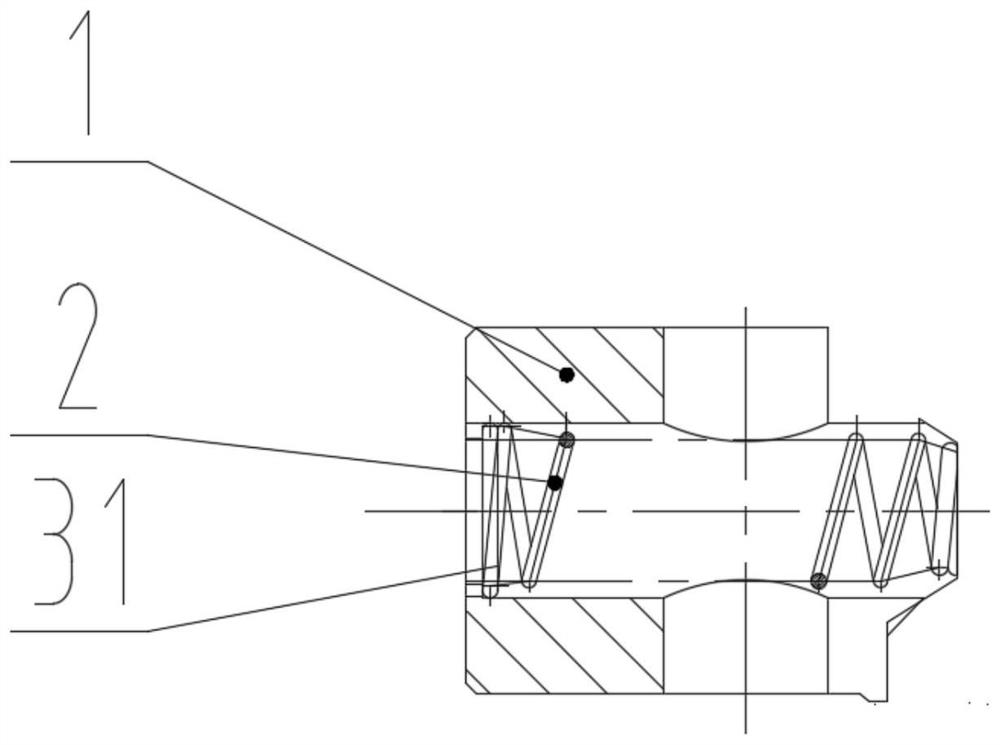

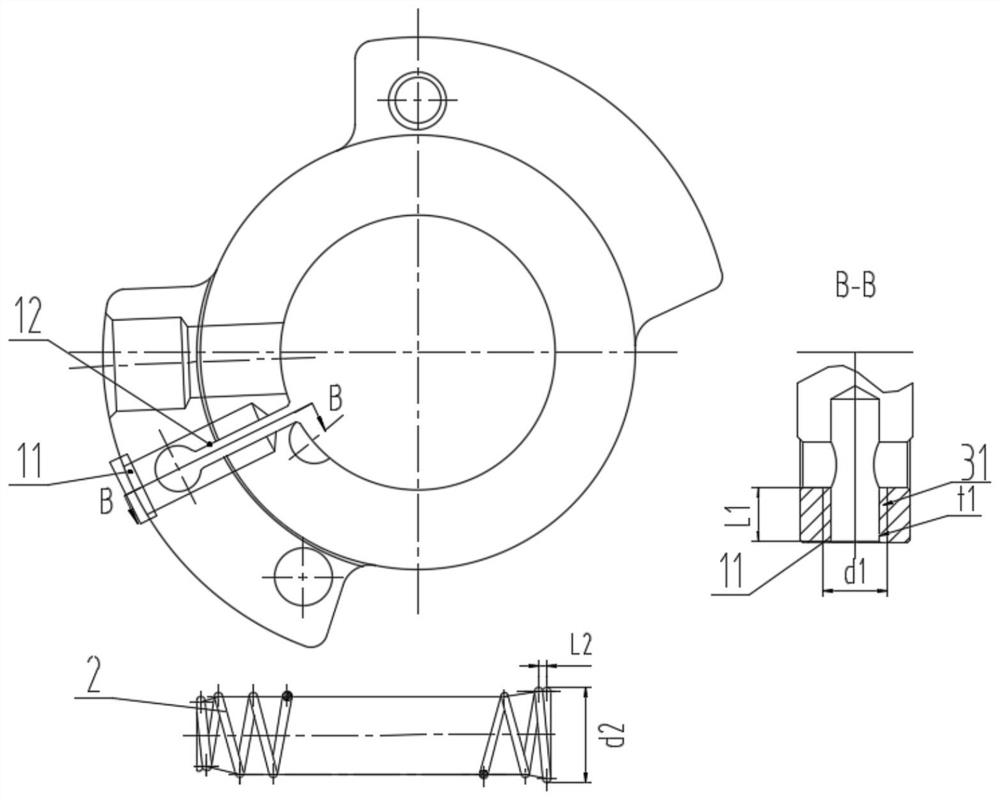

[0038] see in conjunction Figure 1-9 As shown, a compression assembly includes a cylinder structure 1, a spring structure 2 and a limit structure 3. The cylinder structure 1 is provided with a spring hole 11 and a slide groove 12. The spring hole 11 extends along the radial direction of the cylinder structure 1, and the spring The first end of the hole 11 is located on the outer wall of the cylinder structure 1, and the second end of the spring hole 11 extends to the slide groove 12; the slide groove 12 is provided with a slide 4; the spring structure 2 is arranged in the spring hole 11, The spring structure 2 abuts against the sliding piece 4 ; the limit structure 3 is used to limit the movement of the spring structure 2 to prevent the spring structure 2 from breaking away from the spring hole 11 . The spring structure 2 is limited by the limit structure 3, and the spring hole 11 cannot be ejected, so the noise and vibration cannot be transmitted to the casing through the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com