Low-torque pulsation high-speed axial flux surface-mounted permanent magnet motor

A technology of torque pulsation and axial flux, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, magnetic circuit, etc., can solve the problem of low motor power factor and efficiency, large rotor loss, and large mechanical vibration etc. to achieve the effects of reducing vibration and energy loss, improving efficiency, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

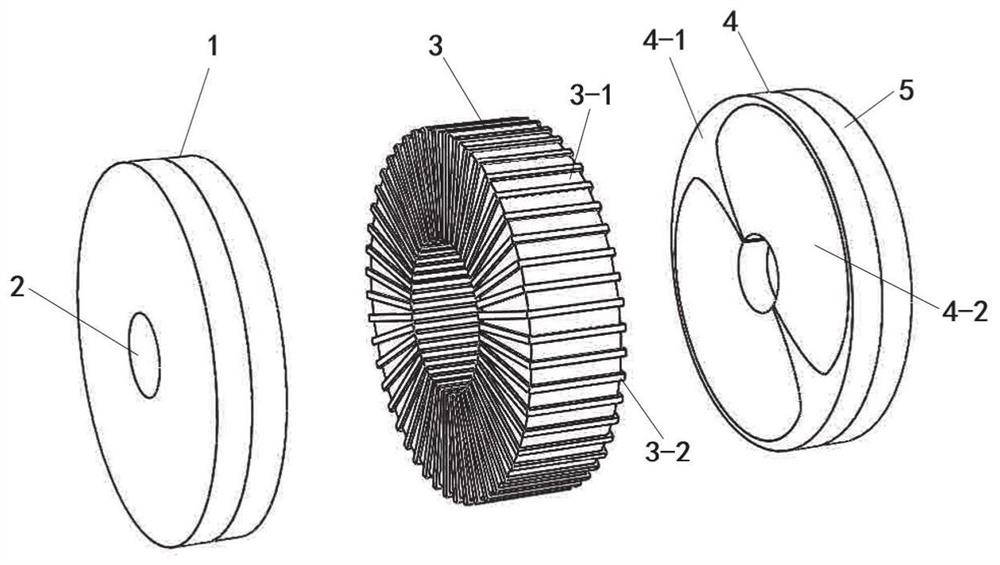

[0033] This embodiment discloses a new low-torque pulsation high-speed axial flux surface-mounted permanent magnet motor, which is mainly composed of an upper permanent magnet rotor 1, a lower permanent magnet rotor 4 and a stator 3, and the stator 3 is on the upper permanent magnet rotor 1 And in the middle of the lower permanent magnet rotor 4.

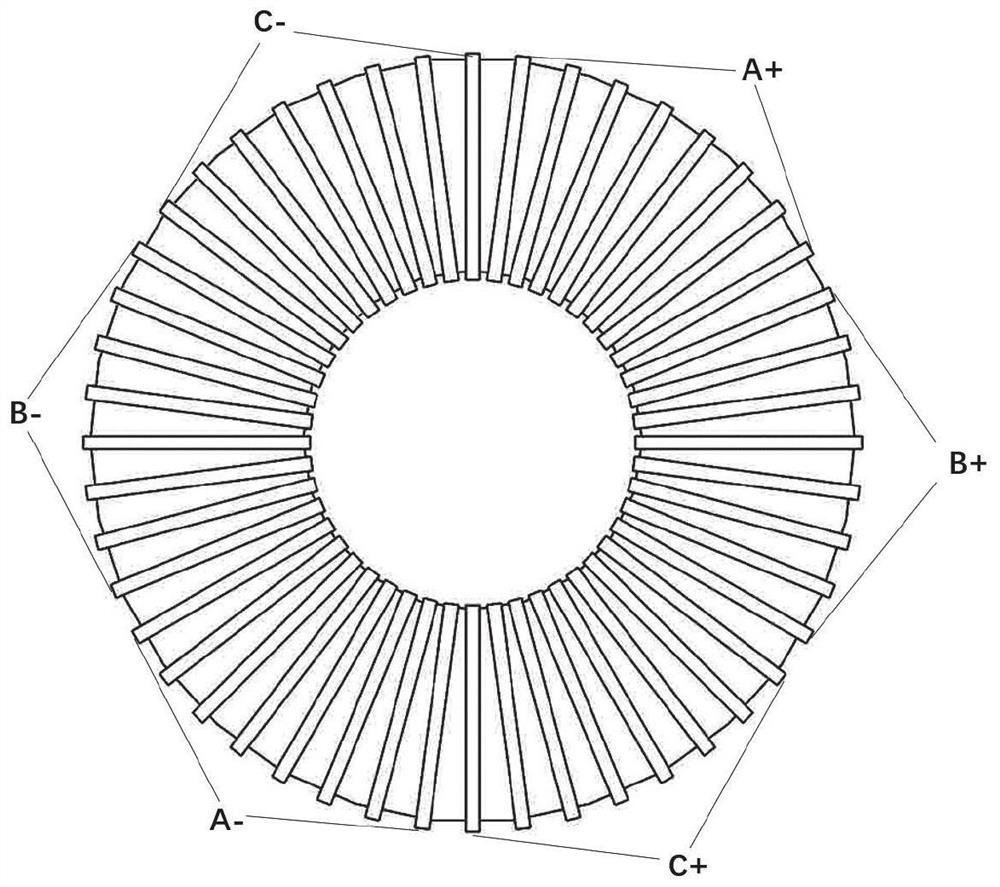

[0034] see figure 1 The stator 3 of the present disclosure includes a stator core 3-1 and a stator winding 3-2. The stator core 3-1 adopts a slotless stator structure and is formed by axially laminating only silicon steel sheets. The stator winding 3-2 is a three-phase winding, and is uniformly wound on the stator core 3-1 along the vertical direction of the circumference of the stator core 3-1 using flat winding wires. In the figure, "+" represents the incoming direction of each phase winding, "-" represents the outgoing direction of each phase winding, A, B, and C represent the three phases of the stator winding 3-2 respectively,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com