Vortex forward-extended double blade impeller sewage pump

A sewage pump, double-blade technology, applied in the field of sewage conveying equipment, can solve the problems of high noise and vibration, reduced pump operation efficiency and stability, increased manufacturing cost, etc. The effect of increasing the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

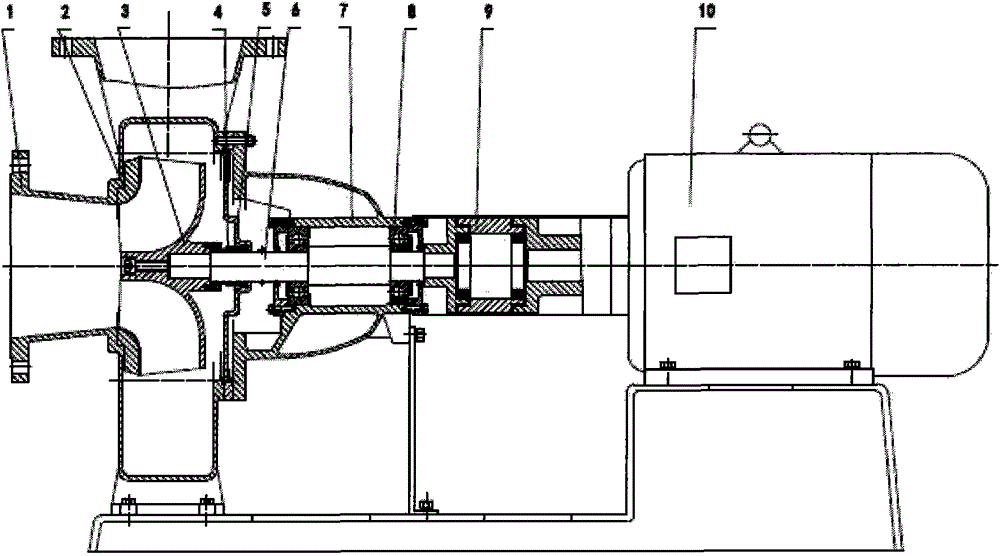

[0017] figure 1 Shown is a schematic structural diagram of a vortex forward-extending double-blade sewage pump, which mainly includes a pump body (1), a front cover (2), an impeller (3), a mechanical seal (4), a pump cover (5), and a pump shaft (6), bearing housing (7), bearing (8), shaft coupling (9), motor (10) and other components. Driven by the motor (10), the impeller (3) rotates at a high speed, forming a low pressure at the inlet of the pump body (1), thereby sucking impurities such as long fibers and large particles. Under the further action of the impeller, the sewage and dirt gain energy and are discharged from the outlet of the pump body. The function of the mechanical seal (4) is to seal the high-pressure liquid so that it does not leak from the gap between the shafts. The pump is connected with the drive motor shaft and installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com