Insulating sleeve

A technology of insulating sleeves and sleeves, applied in the direction of insulators, insulators, electrical components, etc., can solve problems such as difficult insulation and shielding, and achieve good insulation effect, improved insulation and shielding performance, and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

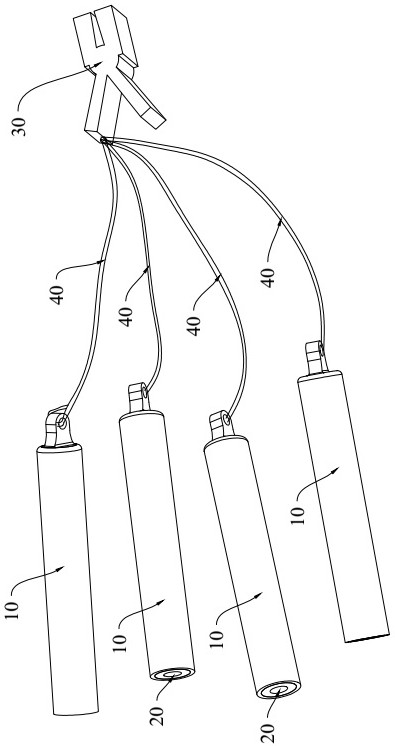

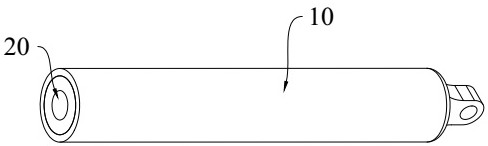

[0029] Please refer to figure 1 and figure 2 , a preferred embodiment of the present invention provides an insulating sleeve, which mainly includes a sleeve body 10 made of insulating material and a soft fastening sleeve 20 .

[0030] Please continue to refer to figure 1 and figure 2 , the sleeve body 10 is a hollow cylinder structure with an opening at one end, specifically a cylindrical cylinder structure, which has a coaxial hollow interior, and the opening is opened at one end and communicates with the hollow interior. The bushing body 10 is made of insulating material. In this preferred embodiment, the bushing body 10 is made of ABS plastic, which has a certain hardness and strength, and has a good insulating effect.

[0031] The soft fastening sleeve 20 is arranged in the hollow inside of the sleeve body 10. The fastening sleeve 20 is made of foamed cotton. The foamed cotton has a good insulating effect, and has good softness, and is easy to squeeze after extrusion....

Embodiment 2

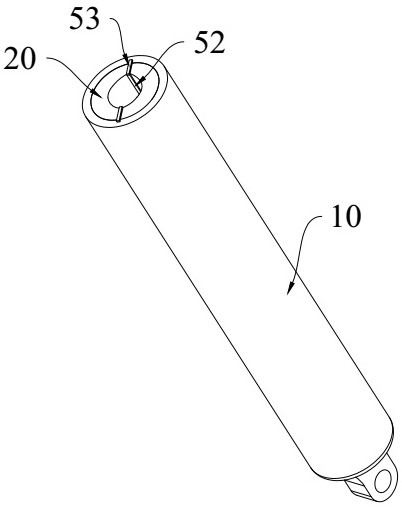

[0039] The difference from Example 1 is that please refer to image 3 and Figure 4 , in this preferred embodiment, the insulating sleeve also includes a damage prevention part 50, the damage prevention part 50 includes an open circuit piece 51 and a pull-out strip 52, the open circuit piece 51 is a circular sheet structure, and one end surface thereof is convex arc surface, the opposite end surface is a concave arc surface, and the edge of the concave arc surface is provided with a pull-out bar 52. In this preferred embodiment, the pull-out bar 52 is a thin rod-shaped structure with a certain strength and hardness , relatively slender, the edge size of the open piece 51 is larger than the hollow interior dimension of the fastening sleeve 20 and can be squeezed into the hollow interior of the fastening sleeve 20 . Considering that the live wire head of the front line may be a sharp structure, when it is inserted into the fastening sleeve 20, it may deflect and pierce or pierc...

Embodiment 3

[0041] The difference from Example 1 is that please refer to Figure 5 , in this preferred embodiment, the opening end of the sleeve body 10 is a conical structure with a large portion close to the opening and a small portion away from the opening, and the sleeve body 10 is grooved radially at the conical structure to The conical structure is divided into a multi-lobe structure. In this preferred embodiment, the fastening sleeve 20 extends to the opening of the sleeve body 10 and has the same slot so that it is also a multi-lobe structure at its end. , the outer circumference of the sleeve body 10 is provided with external threads near the opening end, and the outer circumference of the sleeve body 10 is covered with a threaded sleeve 60, the threaded sleeve 60 has a matching internal thread and is installed on the sleeve by threads On the body 10, and when the threaded sleeve 60 moves toward the opening end of the sleeve body 10 of the multi-lobe structure, it can squeeze the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com