Transformer bushing capable of rapidly dissipating heat

A transformer bushing and bushing technology, which is applied in transformer/inductor cooling, transformer/inductor coil/winding/connection, etc., can solve the problems of high production cost and poor heat dissipation performance of conductive rods, and achieve convenient production and excellent structure Simple and effective in improving heat dissipation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

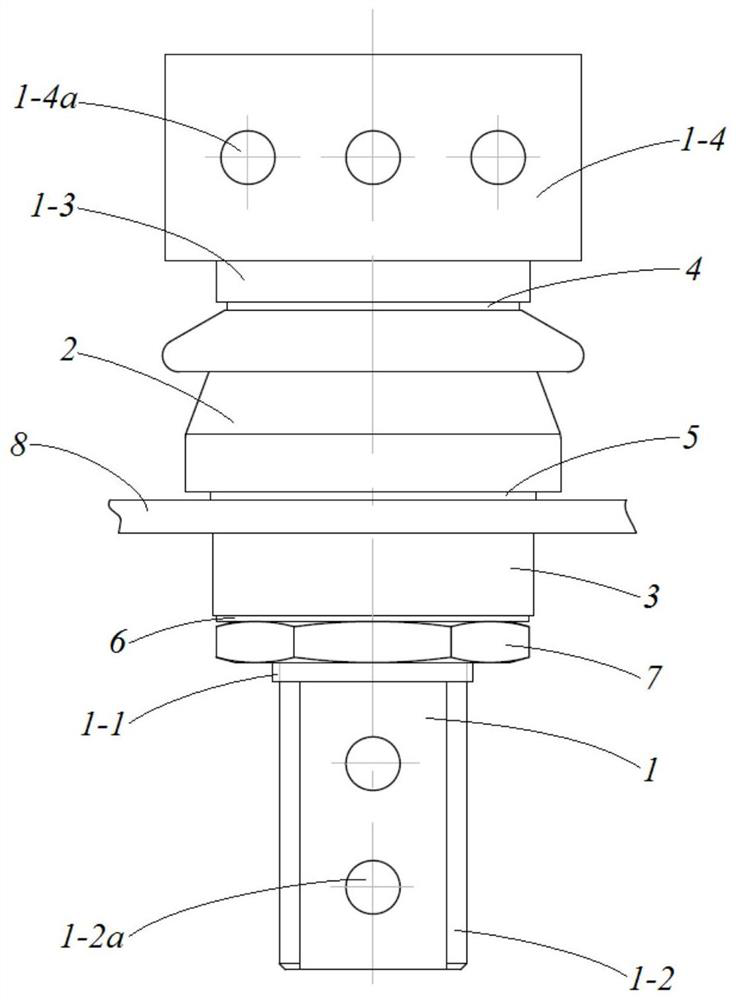

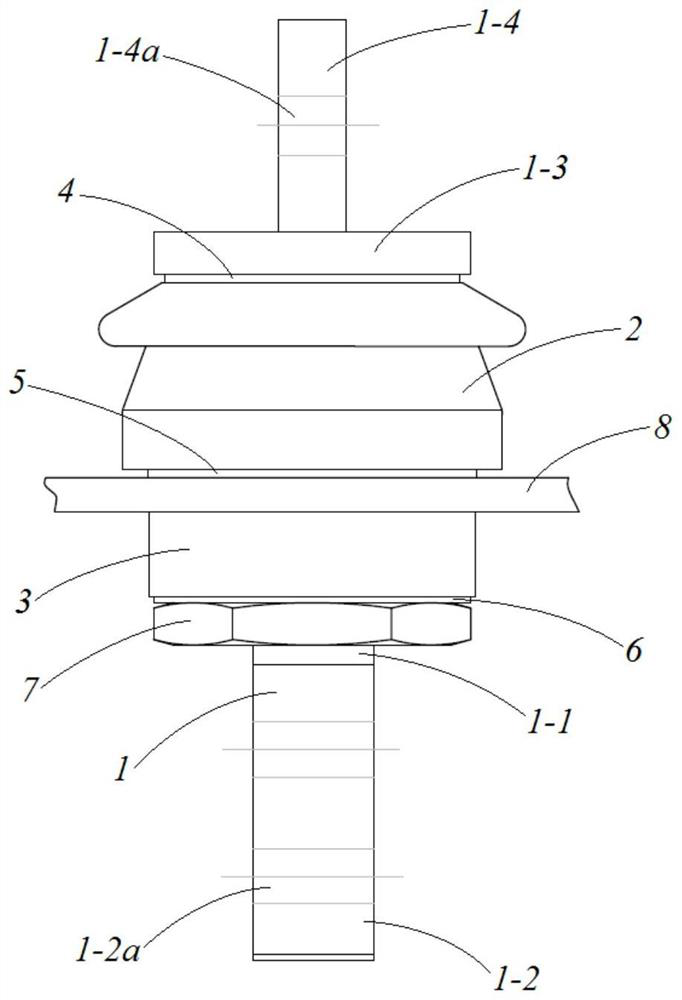

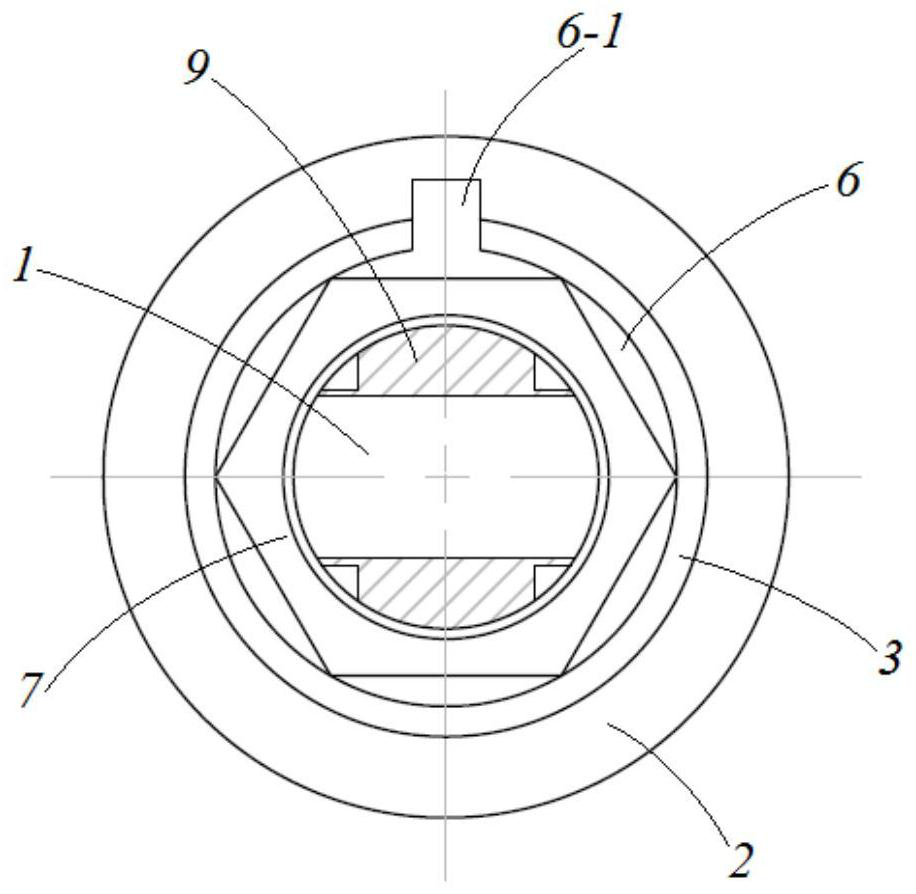

[0034] combine Figure 1 to Figure 6 As shown, a transformer bushing that can quickly dissipate heat in this embodiment includes a conductive rod 1 and an insulating sealing sleeve assembly sleeved on the outside of the conductive rod 1. The conductive rod 1 is used to lead the high and low voltage leads in the transformer to the Outside the oil tank, the insulating sealing sleeve assembly is used to realize the insulation and sealing between the conductive rod 1 and the oil tank wall 8 . Different from the existing transformer bushings, the conductive rod 1 has a cross-sectional shape capable of forming an oil cavity 9 on both sides of the insulating sealing bushing assembly, that is, between the conductive rod 1 and the central through hole of the insulating sealing bushing assembly. An oil cavity 9 is formed between them, and the oil cavity 9 communicates with the cavity inside the oil tank wall 8 of the transformer, so that the oil in the transformer oil tank can enter the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com