Building interior wall coating mechanism

An in-building and coating technology, applied in the direction of building structure and construction, can solve the problems of inconvenient rapid coating of interior wall coating, inconvenient operation for beginners, uneven coating, etc., to achieve cost saving, convenient expansion and contraction control, Avoid wasteful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

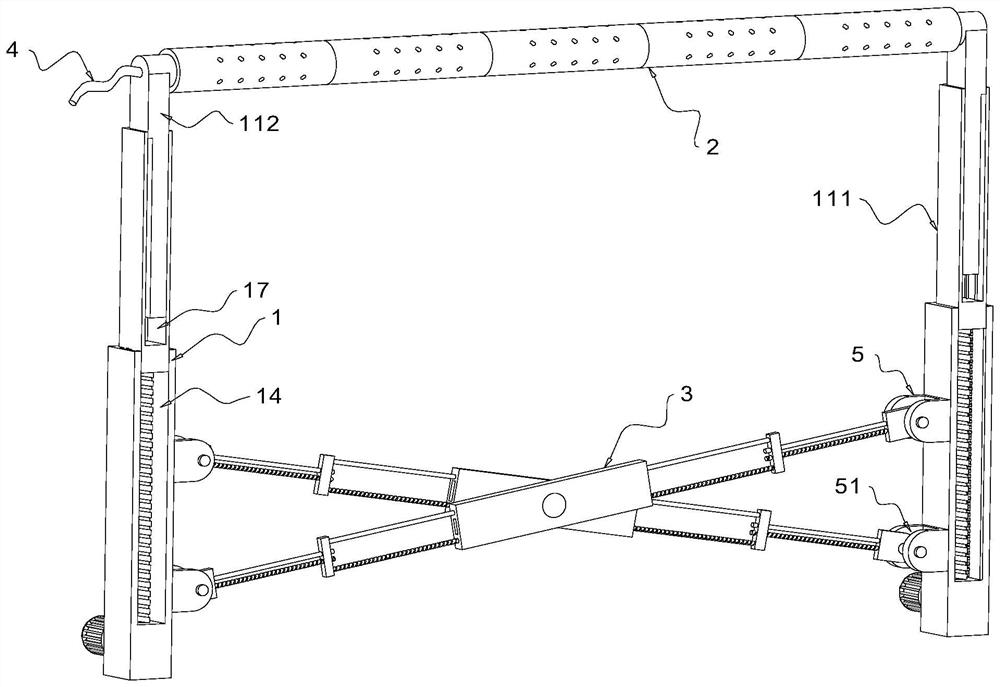

[0030] Specific embodiment one: please refer to Figure 1-6A building interior wall coating mechanism, which includes a pair of telescopic frames 1 and a plurality of assembly brushes 2; the plurality of assembly brushes 2 are connected to each other in the axial direction to form a coating line parallel to the wall surface, and a pair of telescopic frames 1 respectively connected with both ends of the coating line; the first two sections of the telescopic frame 1 protrude through threads, starting from the third section, each subsequent section is synchronously protruded with the second section, except for the first section, Each remaining section shrinks stepwise into the first section. By designing the rolling brush for coating as a splicing pattern, the assembled brush 2 includes a rolling brush shell 21, a connecting head 22, a rotating shaft 24 and a pair of threaded connections. Groove 25; rotating shaft 24 is installed in the rolling brush housing 21 in rotation, and t...

specific Embodiment 2

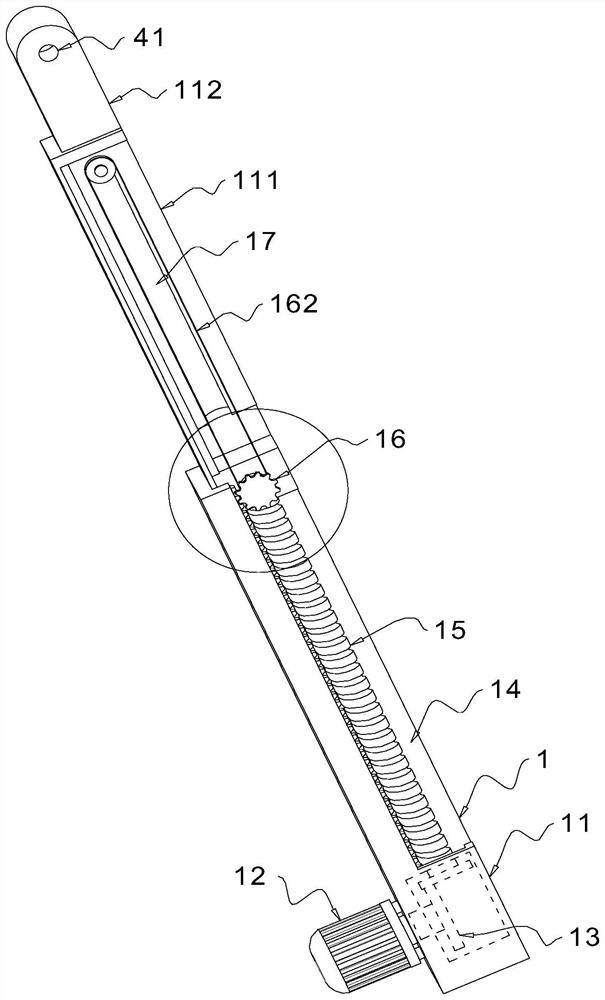

[0037] Specific embodiment two: different from specific embodiment one, telescopic frame 1 also includes connecting frame 112, connecting groove 41 and transmission mechanism 16; The groove that the shaft 15 stretches into, the connecting groove 41 is opened in the connecting frame 112, and the flexible pipe 4 is connected with the connecting groove 41; The frame 112 is fixedly connected with the belt in the belt transmission device 162, and the connection position is close to the bottom wall of the opening groove 17. By using the electric control of the telescopic frame 1, the length direction is more convenient to adapt to the interior walls of different heights through the setting of three sections of expansion and contraction, and the three sections The expansion and contraction is synchronous expansion and contraction, which makes the expansion and contraction control more convenient, does not need to use electronic components to intervene in the middle of the change, save...

specific Embodiment 3

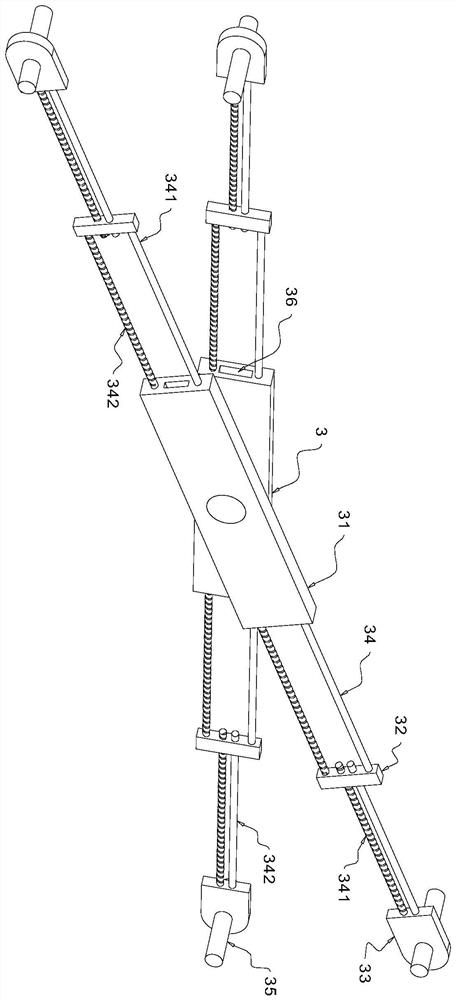

[0039] Specific embodiment three: different from specific embodiment two, the support assembly 3 also includes a pair of connecting plates 32, a pair of placement slots 36 and a second pair of driving mechanisms 34; the first pair of driving mechanisms 34 are connected with a pair of connecting plates 32 connection, the second pair of driving mechanisms 34 are respectively connected to a pair of connecting plates 33, a pair of placement grooves 36 are symmetrically opened in the support plate 31 with respect to the center of the support plate 31, and the second pair of driving mechanisms 34 are respectively placed in a pair of placement grooves 36 Inside, the method of lengthening is used to adapt to the increasing distance between a pair of telescopic frames 1, and the cost is low and easy to maintain.

[0040] The mother frame 11, the sub-frame 111 and the connecting frame 112 are arranged in a ladder shape, but one side of them is all against the wall, and one end of the tel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com