Ball pin support and machining method thereof

A processing method and ball stud technology, which are applied in the field of ball stud parts, can solve the problems that the processing technology is difficult to guarantee and cannot meet the process requirements, and achieve the effect of solving the problem of dimensional tolerance and improving the torque.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

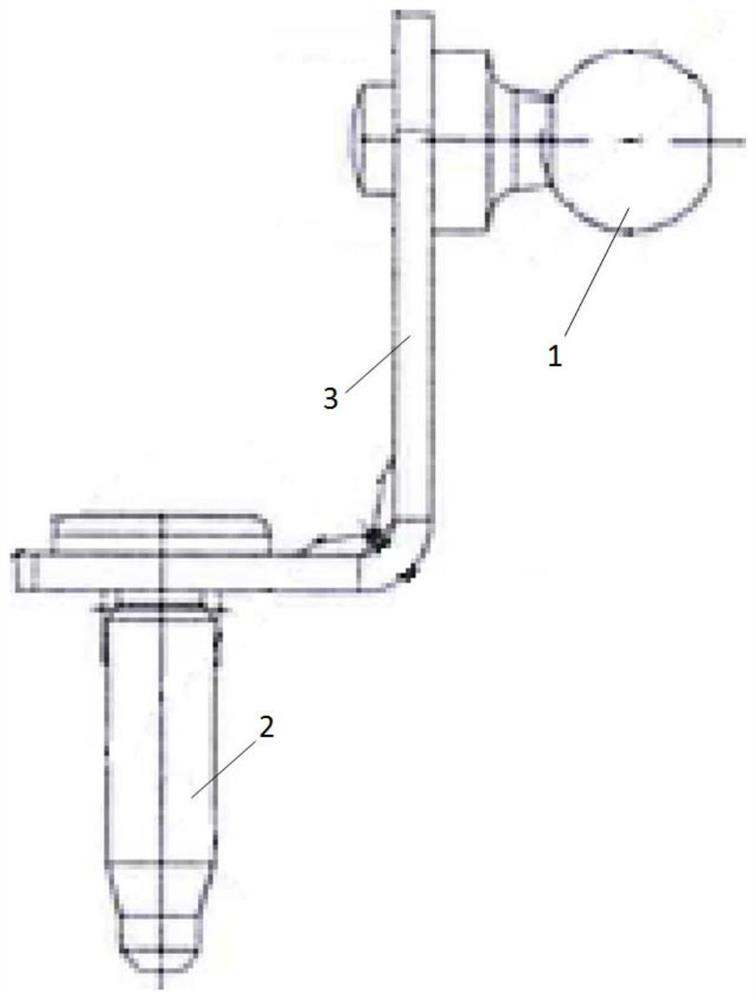

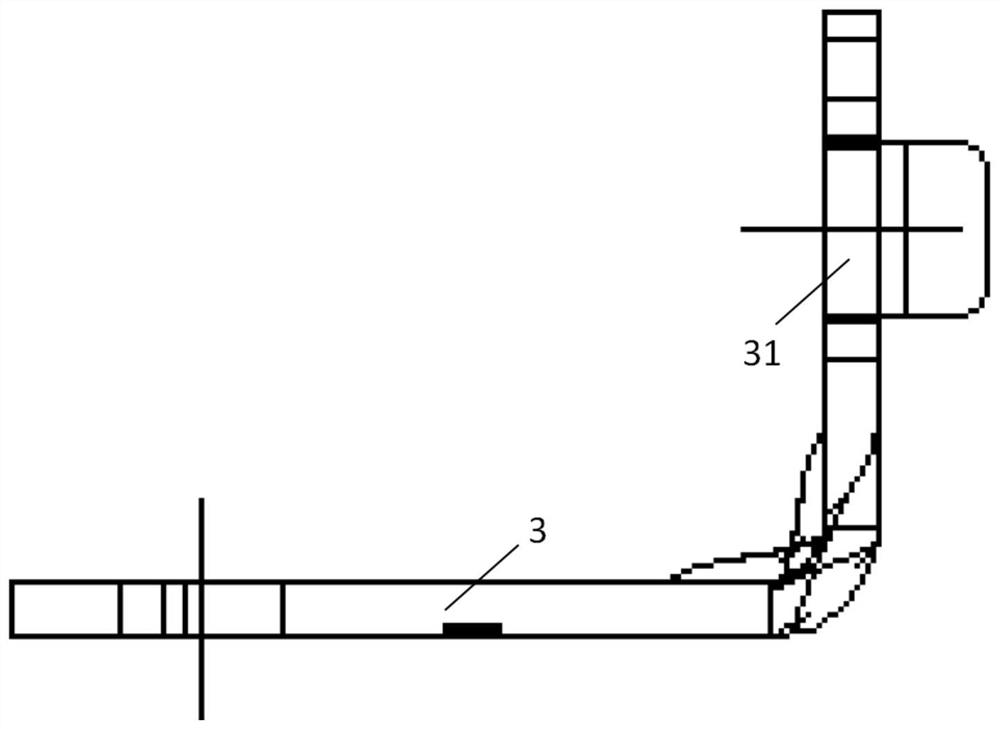

[0027] A ball stud bracket such as Figure 1-3 , the ball stud bracket includes a ball stud 1, a welding screw 2 and a bracket 3; the ball stud 1 is riveted to one end of the bracket 3, and the welding screw 2 is welded to the other end of the bracket 3. The bracket 3 is at a 90° angle. The bending part of the bracket 3 is provided with reinforcing ribs.

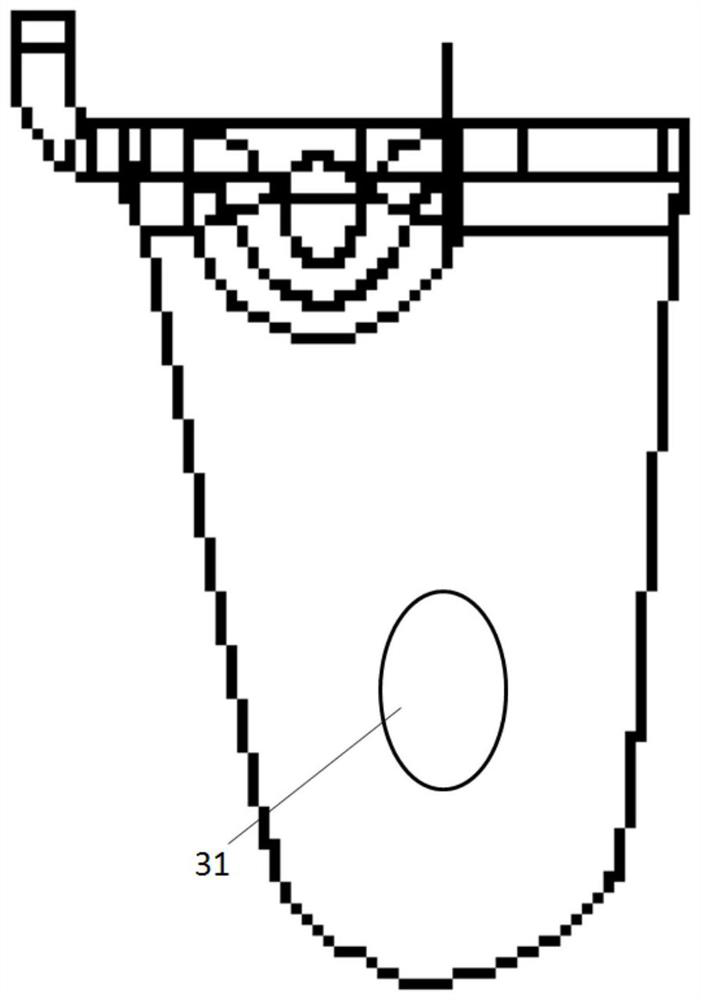

[0028] A riveting hole 31 for riveting the ball stud 1 is opened on the bracket 3 , and the riveting hole 31 is oval. The riveting hole is an oval hole. After riveting through the mold, part 1 of the ball stud enters into the straight part 3 of the bracket to achieve anti-rotation effect and greatly increase the torque. The size of the riveting hole 31 is

[0029] The preparation process of the ball stud 1 is as follows: firstly make a semi-finished product through cold heading; The dimensional tolerance problem of the ball stud was completely solved, the sample delivery was approved, and mass production went smoothly....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com