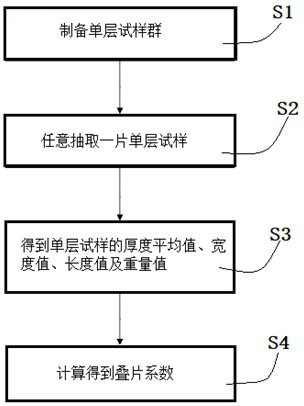

Method for rapidly measuring lamination coefficient of iron-based amorphous strip

A technology of lamination coefficient and iron-based amorphous, which is applied in the direction of measuring devices, analytical materials, and material inspection products, can solve the problems of low accuracy, large errors, and small application range of the ring-rolling method, so as to improve the measurement speed , reduce the impact and eliminate the effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Use the above measurement method to measure the lamination coefficient of the laminated iron core in a certain transformer. First, select a continuous iron-based amorphous strip with a width of 142mm and a length of 3140mm from the laminated iron core in the transformer. Cut it into 15 single-layer samples with the same length to form a single-layer sample group; the length and width of the prepared single-layer samples have a tolerance range, and they can be divided equally; choose one piece from the 15 pieces The cut iron-based amorphous strip is used as a sample, and the average thickness of the single-layer sample is 25.80 μm by scanning with a double-headed laser coaxial displacement meter; The width value of the sample is 142.24mm, and the length value is 299.80mm; the weight value of the single-layer sample measured by a precision electronic balance is 7.0459g; the material density is 7.20g / cm 3 ; According to the obtained average thickness, width value, length v...

Embodiment 2

[0053] If in the actual measurement scene, in order to further reduce the error and improve the accuracy, the measurement method of Embodiment 1 can be carried out twice or even multiple times, that is, to obtain two or more lamination coefficients, and then average the obtained lamination coefficients value to obtain an average value of the lamination coefficient, thereby further improving the accuracy of this measurement method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com