Lens

A lens and lens technology, applied in the field of lenses, can solve the problems of reduced product adaptability, the inability to achieve miniaturization of cameras, and the use of a large number of lenses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

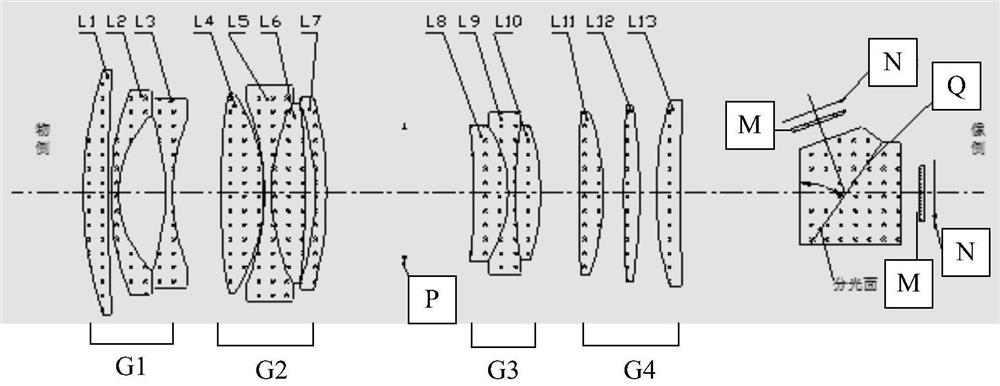

Image

Examples

Embodiment 1

[0084] In the specific implementation process, the curvature radius R, central thickness Tc, refractive index Nd, Abbe constant Vd and conic coefficient k of each lens of the lens meet the conditions listed in Table 1:

[0085]

[0086]

[0087] Table 1

[0088] It should be noted that the mirror serial numbers in Table 1 are figure 1 In the schematic diagram of the lens structure shown, the surface numbers of the lenses from left to right;

[0089] The lens provided by the embodiment of the present invention has the following optical technical indicators:

[0090] Optical total length TTL≤120mm;

[0091] Lens focal length f: 16mm;

[0092] Field of view of the lens: 61°;

[0093] Optical distortion of the lens: -5.1%;

[0094] The aperture FNO. of the lens system: 1.3;

[0095] Lens image size: 1.1".

Embodiment 2

[0097] In the specific implementation process, the curvature radius R, central thickness Tc, refractive index Nd, Abbe constant Vd and conic coefficient k of each lens of the lens meet the conditions listed in Table 2:

[0098]

[0099]

[0100] Table 2

[0101] It should be noted that the mirror serial numbers in Table 2 are figure 1 In the schematic diagram of the lens structure shown, the surface numbers of the lenses from left to right;

[0102] The lens provided by the embodiment of the present invention has the following optical technical indicators:

[0103] Optical total length TTL≤120mm;

[0104] Lens focal length f: 16.5mm;

[0105] Field of view of the lens: 55°;

[0106] Optical distortion of the lens: -4.5%;

[0107] The aperture FNO. of the lens system: 1.2;

[0108] Lens image size: 1.1".

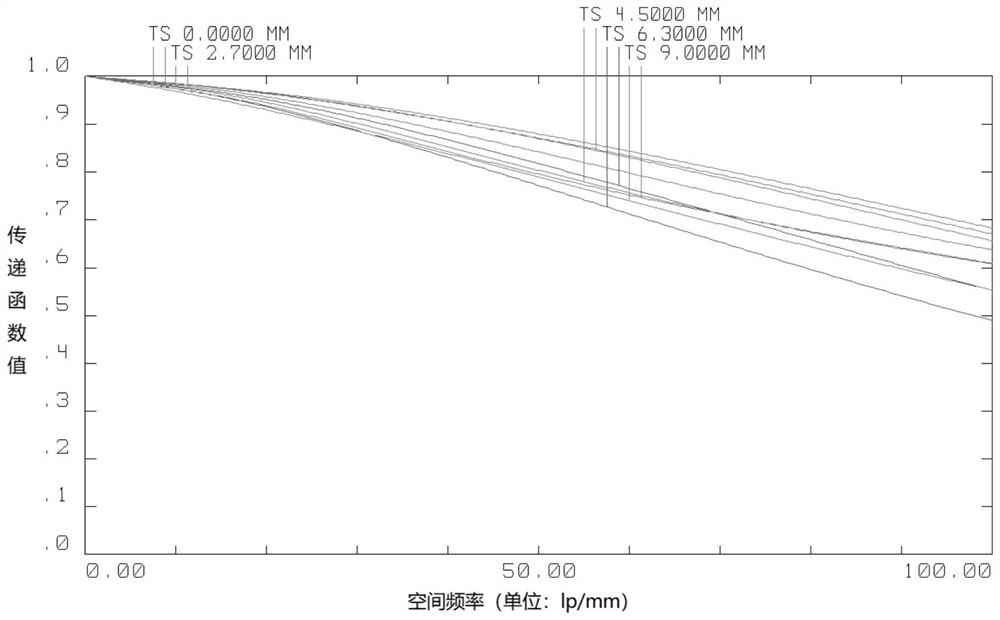

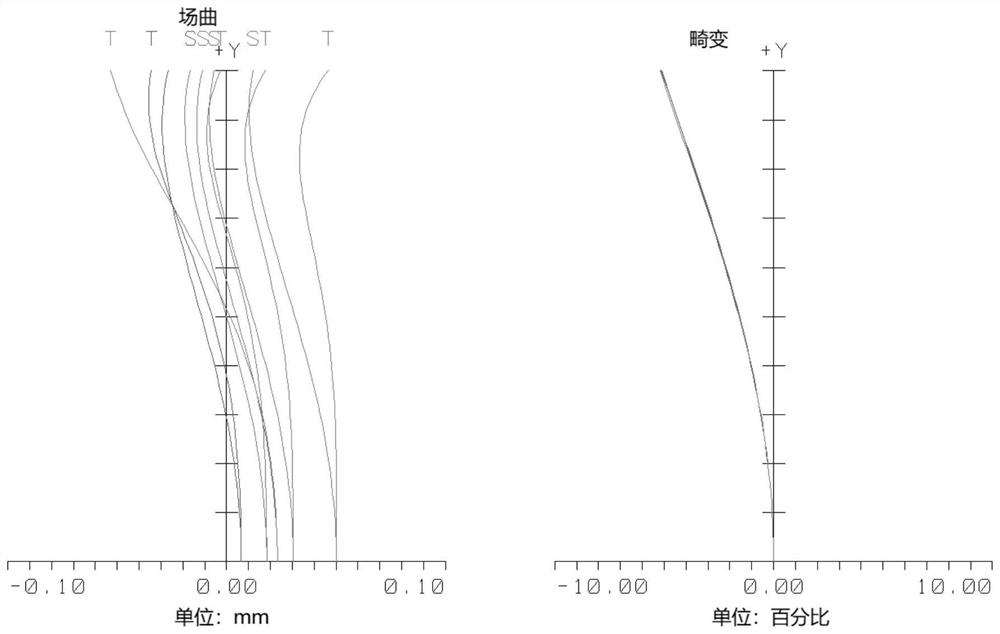

[0109] The lens provided by this embodiment will be further introduced below by analyzing the optical system of the embodiment in detail.

[0110] The optical t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Optical length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com