Horizontal press machine for assembling galvanic pile

A press and horizontal technology, applied in the field of horizontal presses for stack assembly, can solve the problems of low stack assembly accuracy and slow speed, and achieve the effects of good assembly quality, convenient use, and reduced placement difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Reference will now be made in detail to the exemplary embodiments, examples of which are illustrated in the accompanying drawings. When the following description refers to the accompanying drawings, the same numerals in different drawings refer to the same or similar elements unless otherwise indicated. The implementations described in the following exemplary examples do not represent all implementations consistent with the present invention. Rather, they are merely examples of means consistent with aspects of the invention as recited in the appended claims.

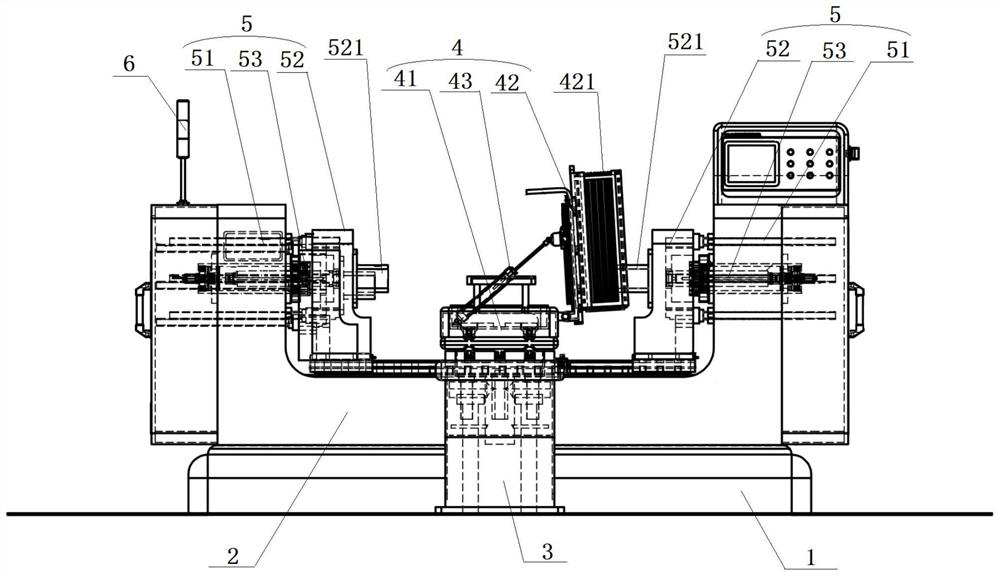

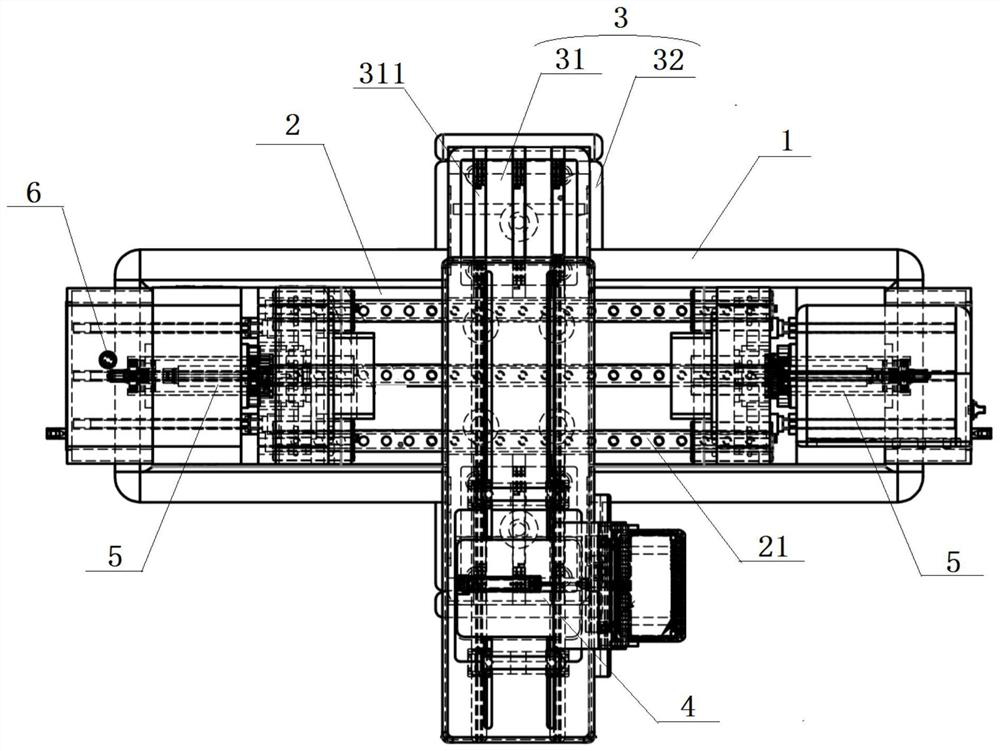

[0042] In order to solve the problems of low assembly accuracy and slow speed of the existing vertical presses, this embodiment provides a horizontal press for stack assembly, see figure 1 , figure 2, the press is mainly composed of a base 1, a first frame 2, a second frame 3, a stage 4, a first driving device, a controller, and two forming clamping parts 5, wherein the base 1 is used for pressing The overall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com