Waterproof structure of wet and dry dual-purpose dust collector motor

A wet and dry dual-purpose, waterproof structure technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of easy wear of the rotating shaft and the motor shell, increased frequency of motor self-protection, and reduced heat dissipation effect of the motor mechanism. To improve the self-radiation efficiency, reduce the probability of entering the motor mechanism, and reduce the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

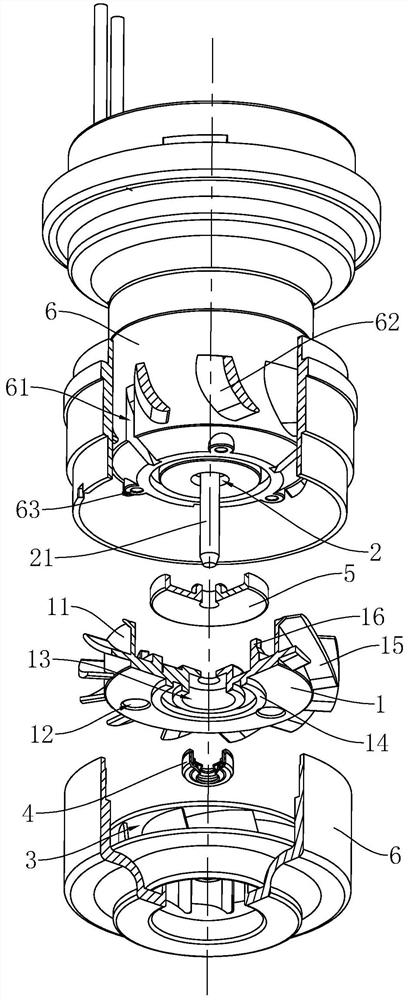

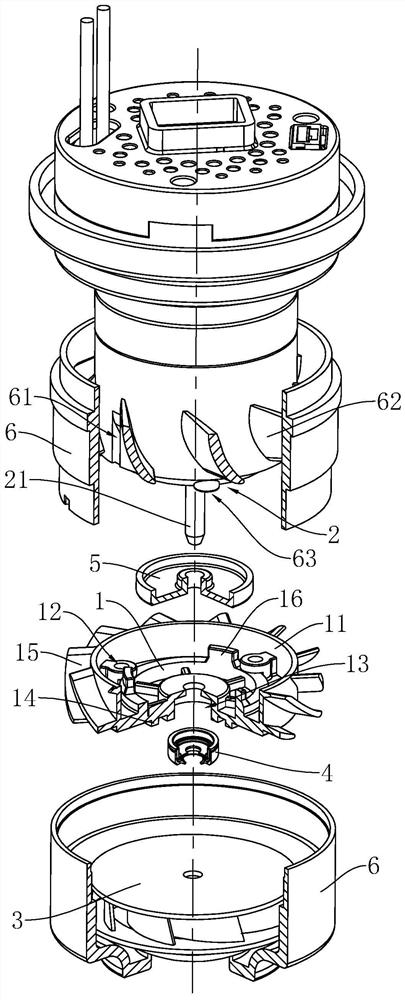

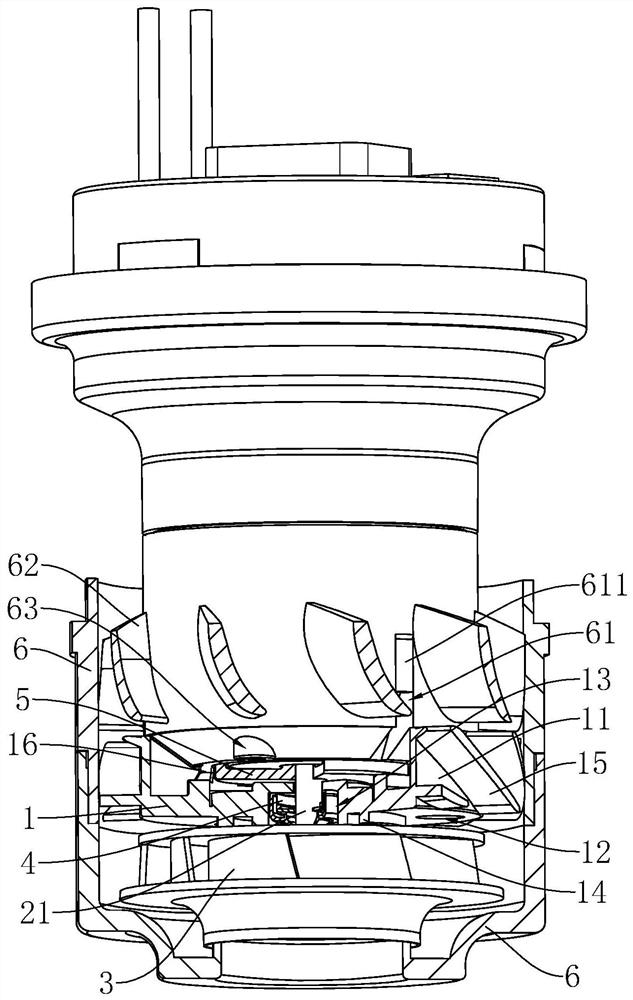

[0039] The embodiment of the present application discloses a waterproof structure for a wet and dry vacuum cleaner motor. refer to figure 1 , a waterproof structure for a wet and dry vacuum cleaner motor, including a waterproof plate 1, three connecting holes 12 are opened on the waterproof plate 1 along the circumferential direction, and the three connecting holes 12 and the three threaded holes provided on the motor housing 6 63 corresponds to facilitate the connection of the waterproof pan 1 to the motor housing 6 through bolts. The rotating shaft 21 connected to the motor mechanism 2 in the motor passes through the axis of the waterproof disk 1, and the rotating shaft 21 is not in contact with the waterproof disk 1 to prevent abrasion between the rotating shaft 21 and the waterproof disk 1.

[0040] refer to figure 2 and image 3, the side of the waterproof disk 1 is connected with a windshield wall 11 along the circumferential direction. When the waterproof disk 1 is ...

Embodiment 2

[0054] The difference between the embodiment of the present application and the first embodiment lies in that the structure on the waterproof pan 1 for positioning with the motor casing 6 is different.

[0055] refer to Figure 4 and Figure 5 , the top wall of the waterproof disk 1 is connected with three wedge-shaped positioning strips 17, and the three positioning strips 17 are evenly distributed on the inner wall of the windshield wall 11, and are connected with the three pressure relief grooves 61 provided on the motor housing 6 one by one. Corresponding fitting fit, so that when the three positioning strips 17 are fitted with each pressure relief groove 61 on the motor housing 6 respectively, the three connection holes 12 on the waterproof disk 1 are respectively connected to the three connection holes 12 on the motor housing 6. The threaded holes 63 correspond to each other, and ensure the stability when the waterproof pan 1 and the motor housing 6 are matched, and fac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com