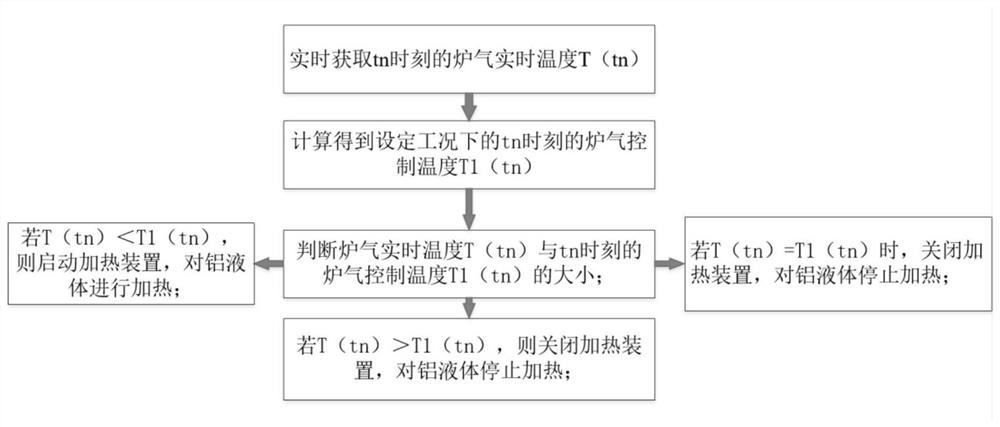

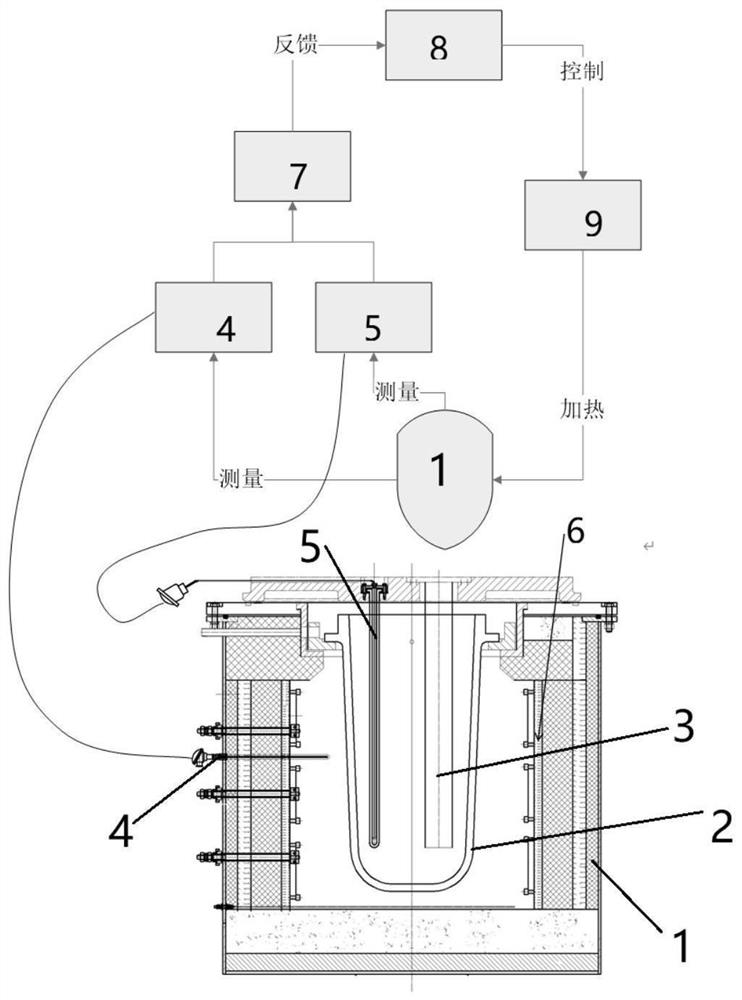

Intelligent temperature control method for low-pressure casting of aluminum alloy melt

A technology of aluminum alloy melt and low pressure casting, applied in the field of aluminum alloy casting, can solve the problems of unmeasurable temperature of alloy melt, fluctuation of casting quality, low control accuracy, etc., to avoid adverse effects, improve accuracy and control accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

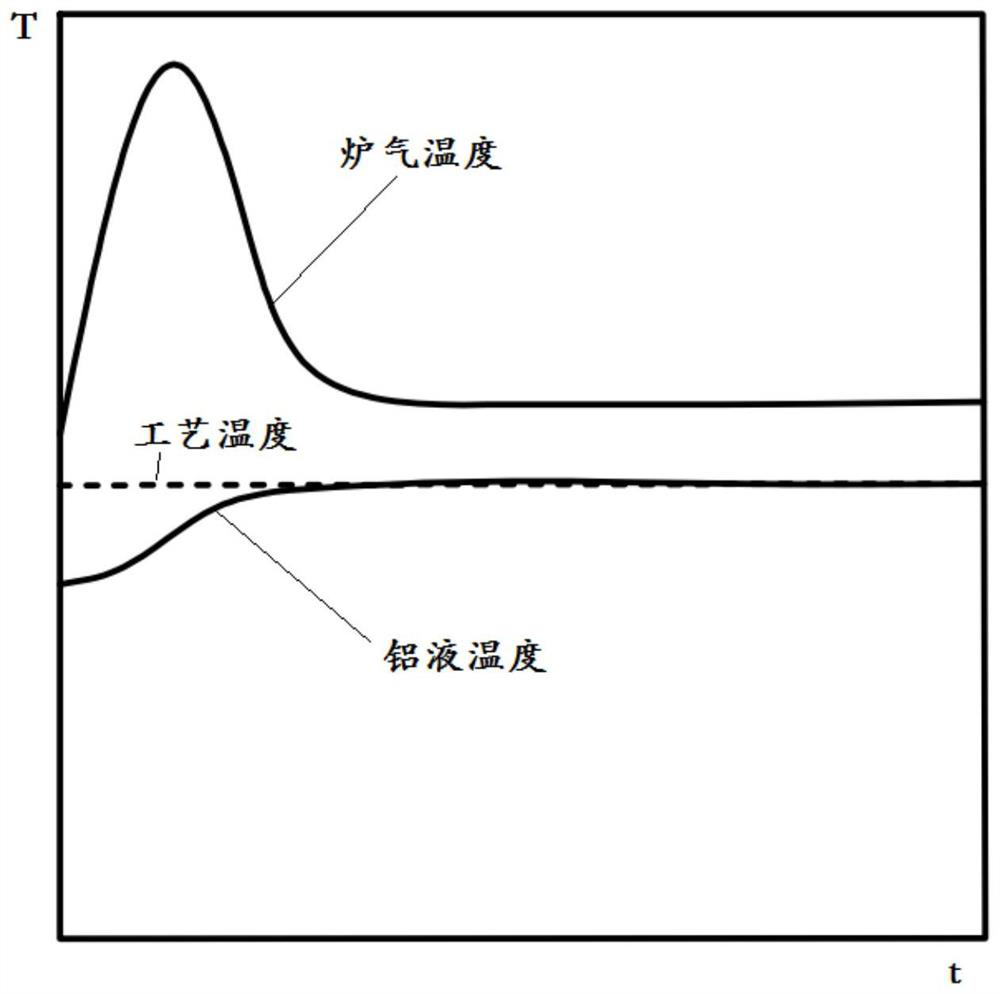

[0138] In this embodiment, β is the temperature control coefficient, and the temperature control coefficient β is selected as 0.05 based on experience.

[0139] Assuming that the real-time temperature T3 of the aluminum liquid is 700°C, the furnace gas equilibrium temperature T2 is set to be 15°C higher than the process control temperature of the aluminum liquid, that is, the furnace gas equilibrium temperature T2 is 715°C, and the temperature of the aluminum liquid can be kept basically stable at this temperature.

[0140] If the temperature of the molten aluminum is increased by 5°C, that is, △T2=5°C, that is, the process control temperature of the molten aluminum is T4=705°C, and the corresponding furnace gas equilibrium temperature T2 is 720°C. Set the start of temperature control as time t0, and the end of temperature control as time t1. Then the calculation process and result of the furnace gas temperature difference △T1(t0) at the moment t0 in the initial stage of tempe...

Embodiment 2

[0157] In the above example 1, if the actual temperature control coefficient β=△T2 / △T1=2.5°C / 50°C=0.05 is estimated to be inaccurate, at a certain tm moment, if the real-time temperature of the furnace gas rises to the highest value of 770°C Start to stop heating, that is, the furnace gas control temperature T1(tm) at this time is also 770°C, and the real-time temperature T3(tm) of the aluminum liquid measured at this time is 702.5°C. As the furnace gas temperature drops to the furnace gas equilibrium temperature T2, the real-time temperature T3 (t1) of the molten aluminum changes the process control temperature T4 to 705.5°C. Then during the cooling process, the actual furnace gas temperature difference △T1 is:

[0158] ΔT1=T1(tm)-T2=770°C-720°C=50°C;

[0159] The actual aluminum liquid temperature difference △T2 is:

[0160] ΔT2=T4-T3(tm)=705.5°C-702.5°C=3°C;

[0161] Then the actual temperature control coefficient β is:

[0162] β=ΔT2 / ΔT1=3°C / 50°C=0.06.

[0163]Then re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com