Internal chamfering equipment of drainage pipe for water conservancy project

A technology of water conservancy projects and drainage pipes, which is applied to metal processing equipment, drainage structures, sewer pipe systems, etc., to achieve the effects of avoiding waste of water resources, improving work efficiency, and recycling water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

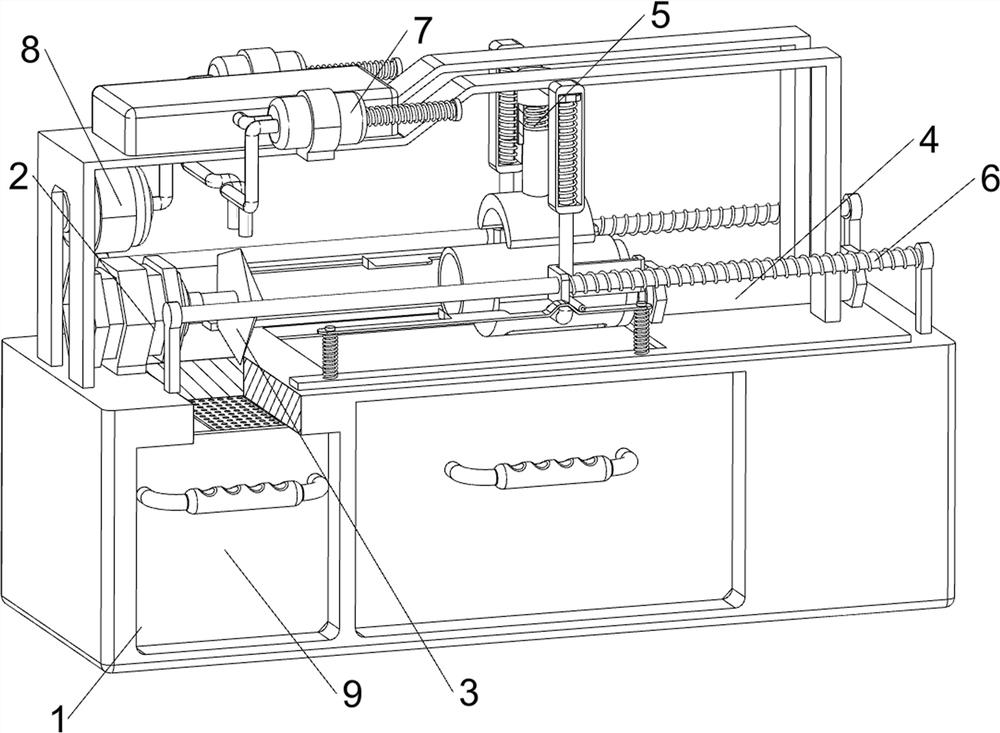

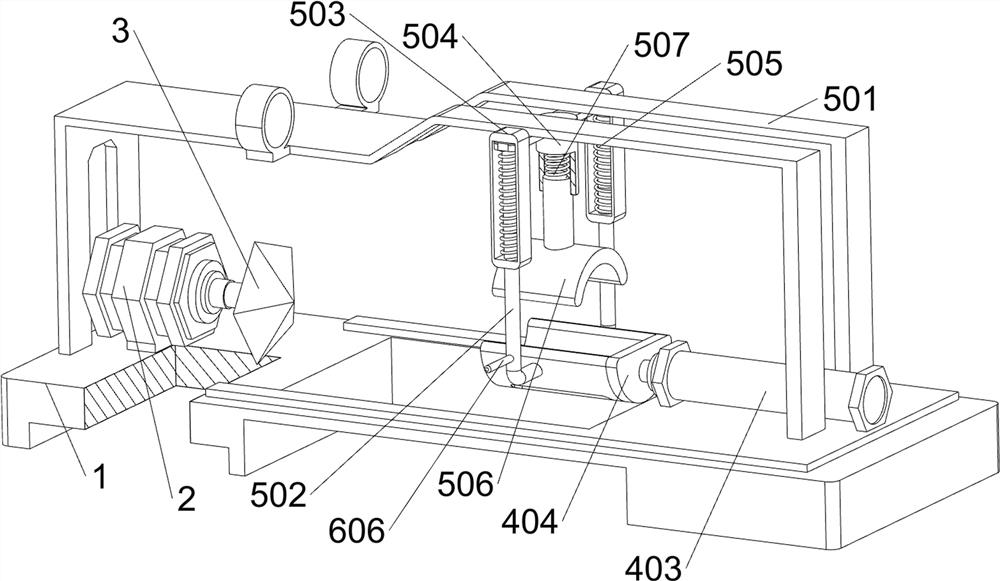

[0026] A kind of internal chamfering equipment for drainage pipes used in water conservancy projects, such as Figure 1-Figure 3 As shown, it includes a box body 1, a motor 2, a chamfering knife 3, a placement component 4 and a pressing component 5. A motor 2 is provided in the middle of the left side of the box body 1, and a chamfering knife 3 is provided on the output shaft of the motor 2. A placement component 4 is provided on the box body 1 , and a compression component 5 is provided on the inner upper side of the box body 1 , and the compression component 5 is connected with the placement component 4 .

[0027] The placement assembly 4 includes a box door 401, a control panel 402, a cylinder 403 and a placement slot 404. The box door 401 is slidingly provided in the middle of the front side of the box body 1, and a control panel 402 is provided on the upper right side of the front side of the box body 1. The box body 1 The inner middle right side is provided with a cylind...

Embodiment 2

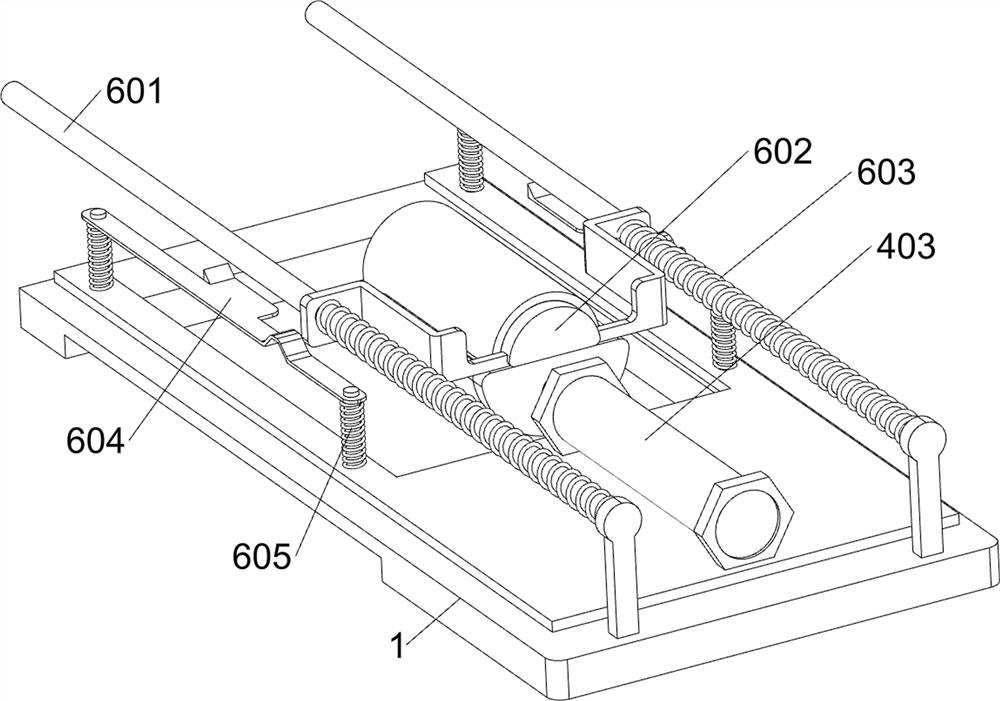

[0031] On the basis of Example 1, such as Figure 4-Figure 7As shown, a discharge assembly 6 is also included. The discharge assembly 6 includes a guide rod 601, a discharge plate 602, a third spring 603, a wedge plate 604, a fourth spring 605 and a connecting rod 606. The symmetrical sliding type is provided with a wedge-shaped plate 604, and the left side of the wedge-shaped plate 604 is provided with an oblique angle. The inner middle of the box 1 is provided with a guide rod 601 symmetrically, and the sliding type is provided with a discharge plate 602 in the middle of the guide rod 601. A support rod 502 cooperates with the unloading plate 602, and the unloading plate 602 cooperates with the bevel on the wedge plate 604, and the third spring 603 is arranged between the unloading plate 602 and the guide rod 601, and the third spring 603 is set on the guide rod On 601, fourth springs 605 are symmetrically arranged between the wedge plate 604 and the box body 1, and connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com