Tire vulcanization equipment

A tire vulcanization and equipment technology, which is applied to tires, other household appliances, household appliances, etc., can solve the problems of motor damage and shortened service life of the motor, and achieve the effects of improving service life, avoiding shortened service life, and avoiding high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

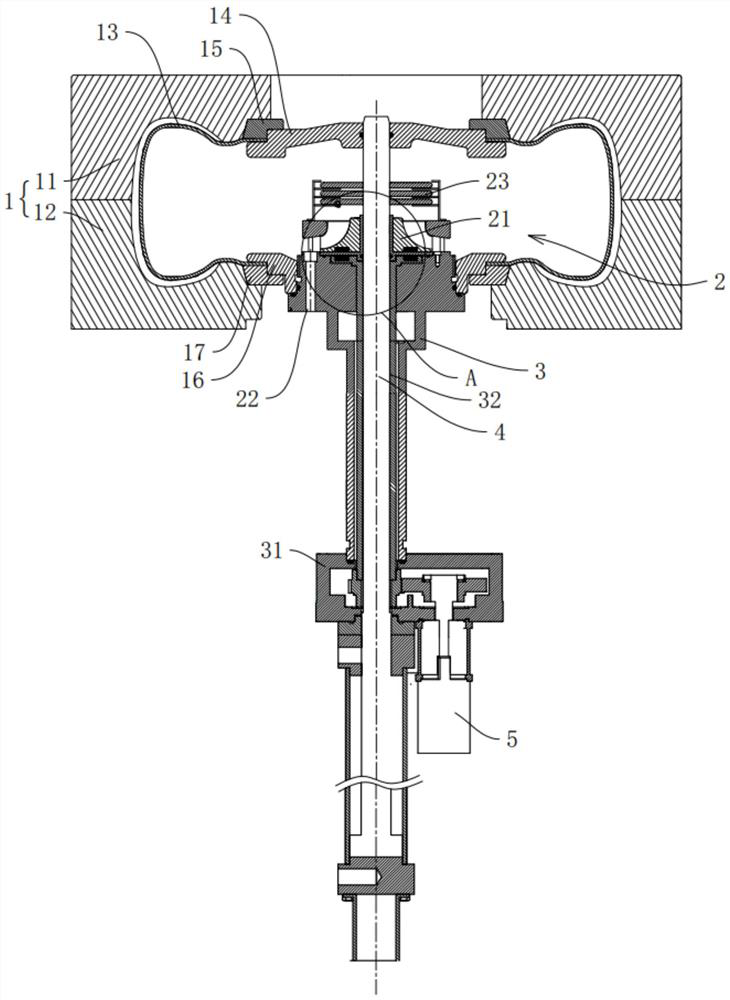

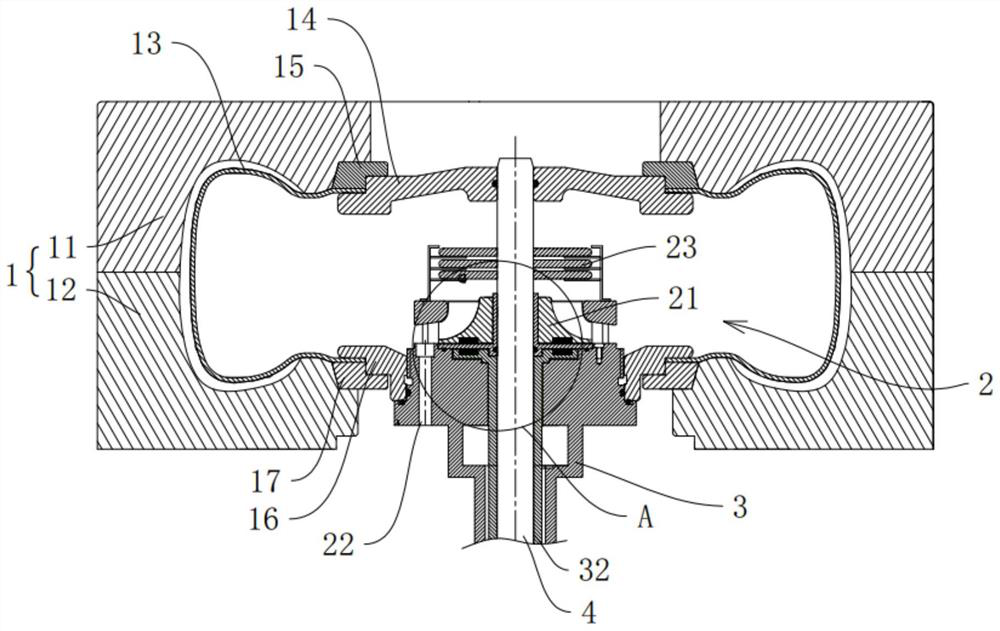

[0039] refer to figure 1 , the invention discloses a tire vulcanization equipment, comprising a mold assembly 1, a ring seat assembly 2 arranged inside the mold assembly 1, a cylinder assembly supporting the ring seat assembly 2, a driving member and a transmission assembly, and the ring seat assembly 2 is provided with a gas circulation fan 21, and the driving part drives the gas circulation fan 21 to rotate through the transmission assembly. The cylinder assembly includes the cylinder body 3 and the transmission box 31 arranged on the cylinder body 3.

[0040] refer to figure 1 and figure 2, The mold assembly 1 is a two-half mould, and can also be a two-half active mould, an upper-opening active mould, and a lower-opening active mould. Specifically, the mold assembly 1 includes an upper mold 11 and a lower mold 12. A vulcanization bladder 13 for molding the tire is also provided inside the mold assembly 1. The ring seat assembly 2 is located inside the vulcanization bladd...

Embodiment 2

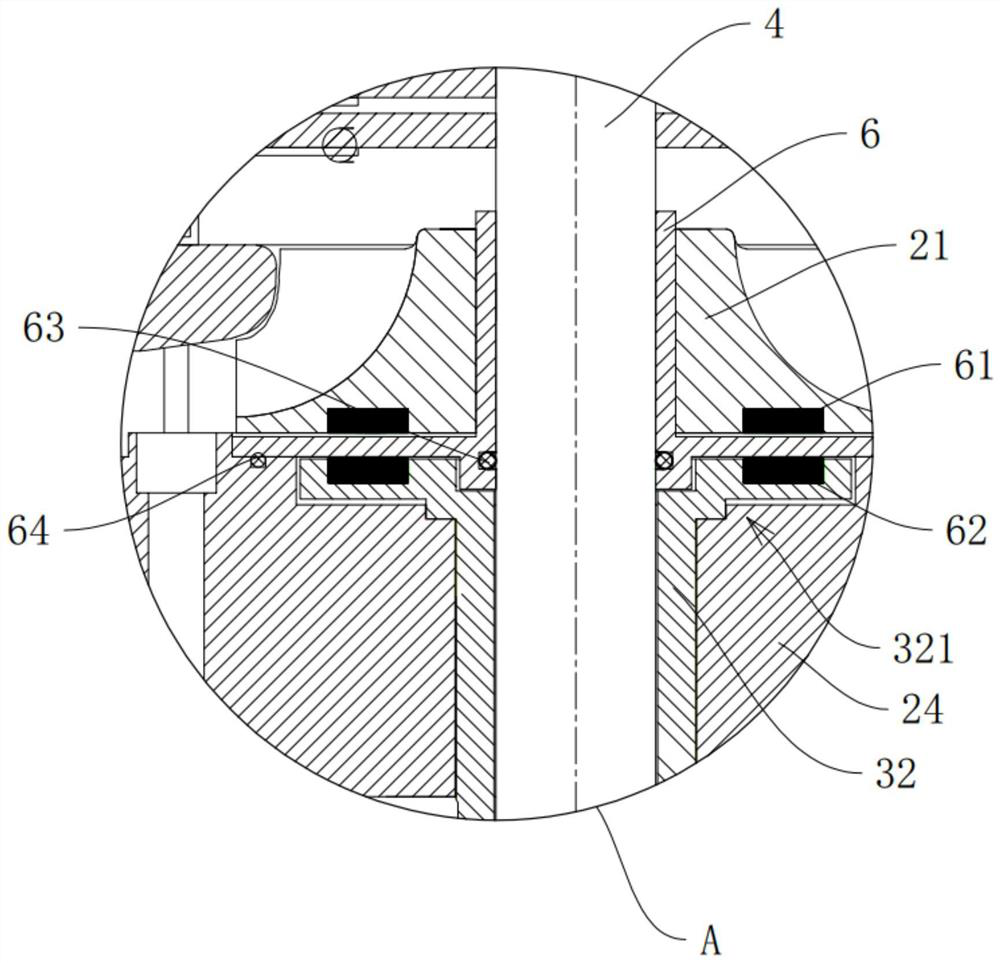

[0049] The difference between the second embodiment and the first embodiment lies in that the positions of the first magnetic body 61 and the second magnetic body 62 are different. refer to Figure 8 and Figure 9 , the transmission assembly includes a first transmission part and a second transmission part, the first transmission part is the first shaft body 311 , and the second transmission part is the second shaft body 51 . The tire vulcanization equipment also includes a transmission box 31, the transmission box 31 is arranged on the cylinder body 3, the transmission box 31 is penetrated by the rotating shaft 32, and the rotating shaft 32 is a hollow shaft, which is sleeved on the center rod 4 and is arranged in the cylinder body 3 , the top of the rotating shaft 32 is connected with the gas circulation fan 21 and drives it to rotate. The first shaft body 311 is arranged in the transmission box 31, and the first shaft body 311 and the rotating shaft 32 are gear meshed. Of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com