A kind of alkali-resistant gypsum retarder and preparation method thereof

A gypsum retarder and alkali-resistant technology, which is applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of reduced retarding effect, achieve enhanced retarding effect, maintain stability, prolong The effect of clotting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

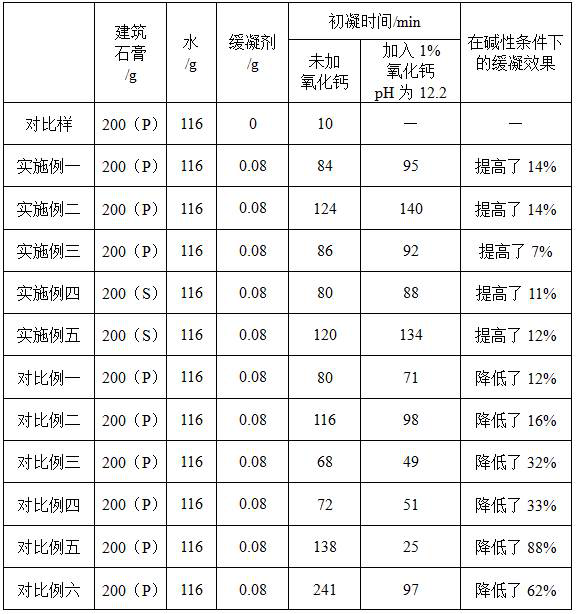

Examples

Embodiment 1

[0018] By weight, mix 35% lysine hydrochloride, 30% maleic anhydride and 1.5 times water to make a mixed solution, then add 26% sodium hydroxide and 9% steel slag to adjust the pH of the system to 10 , reacted at 100°C for 2h, cooled to room temperature and dried to obtain a powder retarder. Wherein, the amount of water added is by weight of amino acid and maleic anhydride.

Embodiment 2

[0020] By weight, mix 47% lysine hydrochloride, 26% maleic anhydride and 1 times water to make a mixed solution, then add 20% sodium hydroxide and 7% steel slag to adjust the pH of the system To 7, react at 110°C for 0.5h, cool to room temperature and dry to obtain a powder retarder. Wherein, the amount of water added is by weight of amino acid and maleic anhydride.

Embodiment 3

[0022] By weight, mix 45% lysine hydrochloride, 29% maleic anhydride and 1.4 times water to make a mixed solution, then add 16% sodium hydroxide and 10% steel slag to adjust the pH of the system To 6, react at 90°C for 1 h, cool to room temperature and dry to obtain a powder retarder. Wherein, the amount of water added is by weight of amino acid and maleic anhydride.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com