Micron fiber reinforced cellulose composite aerogel as well as preparation method and application thereof

A composite airgel and micron fiber technology, which is applied in separation methods, chemical instruments and methods, alkali metal compounds, etc., can solve the problem of poor mechanical properties of cellulose airgel, failure to meet the needs of use, and poor oil absorption and sound absorption effects etc. to achieve good mechanical properties, low density and high oil affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

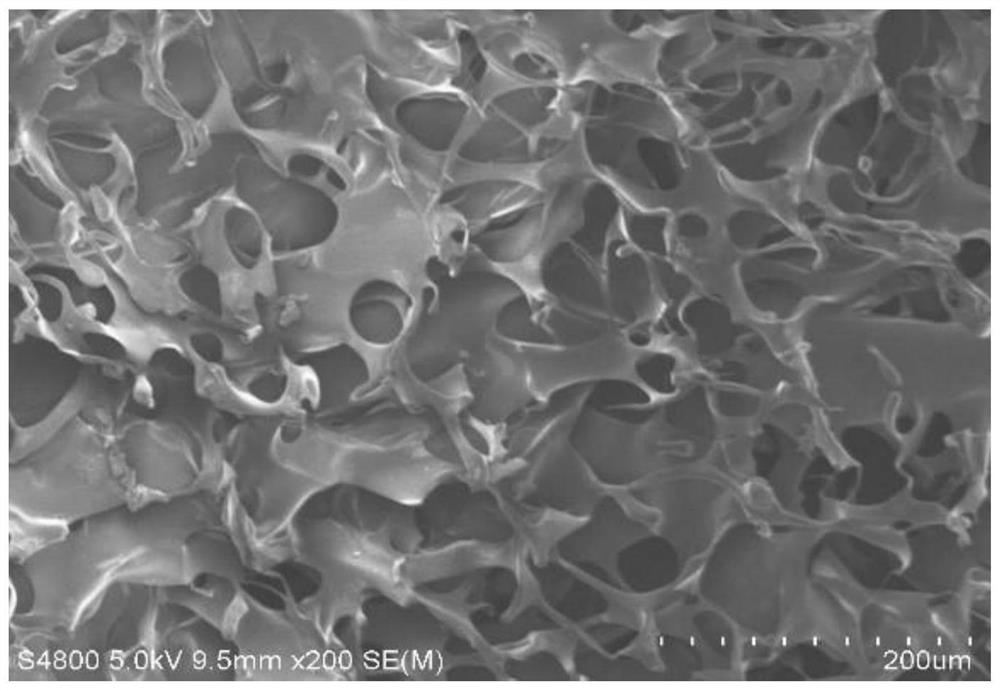

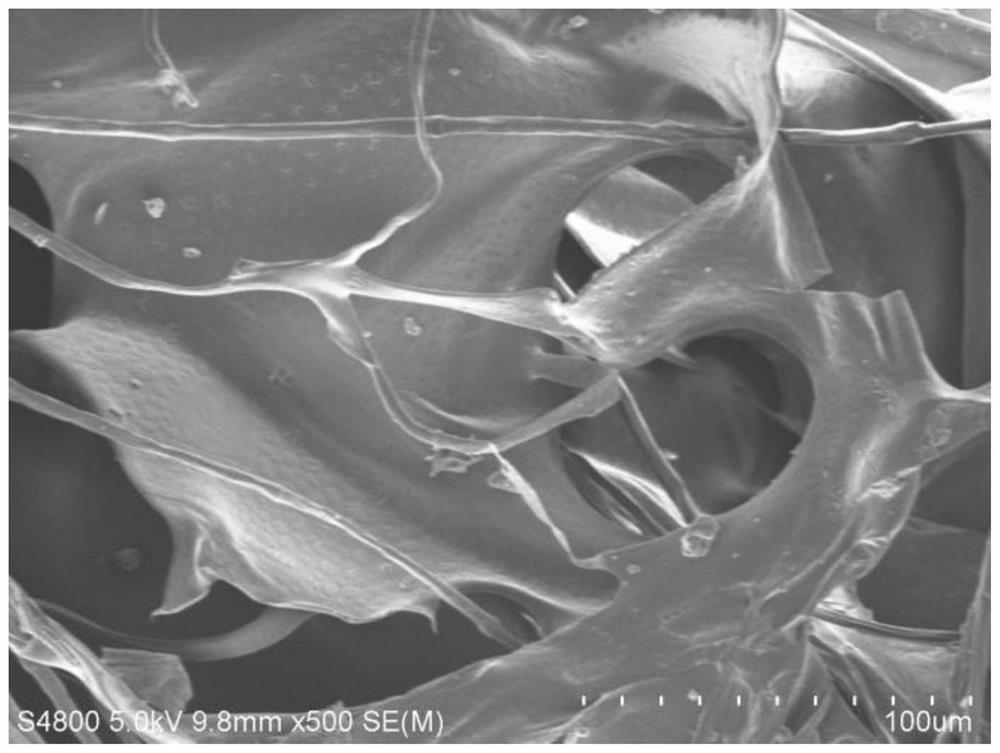

[0036] Preparation of Carboxymethyl Cellulose Composite Airgel Containing Feather Silk

[0037] Get the feather silk of 0.4g and the sodium dodecylbenzenesulfonate of 0.1g, be dissolved in 200ml deionized water then, place in the magnetic stirrer and mix evenly; Take by weighing 6g sodium carboxymethylcellulose and slowly add in the solution, Thoroughly stir to dissolve; measure 6g of glutaraldehyde (50%) as a cross-linking agent and add to the mixed solution, fully stir evenly. Let it stand for 72 hours, import it into the mold and put it into the refrigerator for pre-freezing for 4 hours, then refrigerate for 12 hours, then put it into a vacuum freeze dryer and dry it for 72 hours to obtain the carboxymethyl cellulose composite airgel containing feather silk.

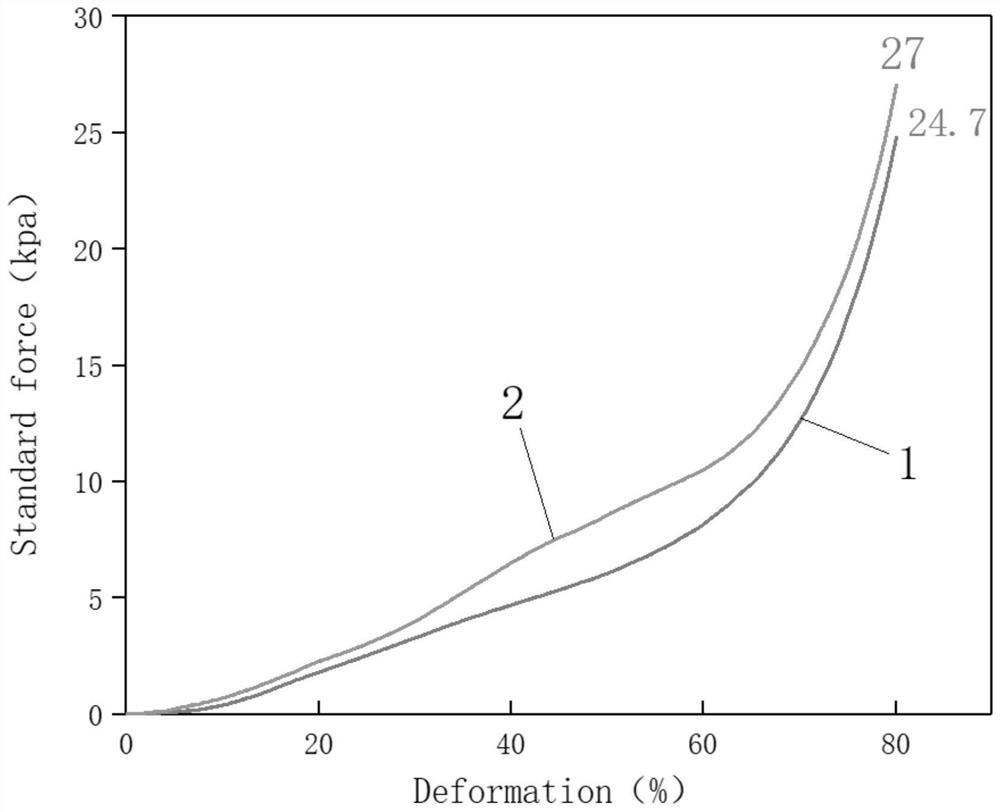

[0038] The mass and size of the composite airgel were measured with a balance and a digital vernier caliper, the results are shown in Table 1, and the density calculation of the composite airgel is shown in the formul...

Embodiment 2

[0067] Carboxymethylcellulose Composite Airgel Containing Dumplings

[0068] Take 0.4g of velvet and 0.1g of sodium dodecylbenzenesulfonate, then dissolve them in 200ml of deionized water, place them in a magnetic stirrer and mix them evenly; weigh 6g of carboxymethylcellulose sodium and slowly add them into the solution, Thoroughly stir to dissolve; measure 6g of glutaraldehyde (50%) as a cross-linking agent and add to the mixed solution, fully stir evenly. Let it stand for 72 hours, introduce it into the mold and put it into the refrigerator for pre-freezing for 4 hours, then refrigerate it for 12 hours, put it into a vacuum freeze dryer and dry it for 72 hours to obtain the carboxymethyl cellulose composite airgel containing velvet.

[0069] The testing methods of density and porosity are as in the above-mentioned Example 1, and the results are shown in Table 4.

[0070] Table 4

[0071] Density (g / cm 3 )

Porosity Composite airgel with fluff 0.0074...

Embodiment 3

[0080] Preparation of hydroxyethyl cellulose composite airgel containing feather silk:

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap