Coplanar rod type truss node

A rod-type and truss technology, applied in the field of coplanar rod-type truss joints, can solve problems such as difficulty, delay in construction period, and inability to establish connections in truss structures, so as to improve construction efficiency and reduce construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

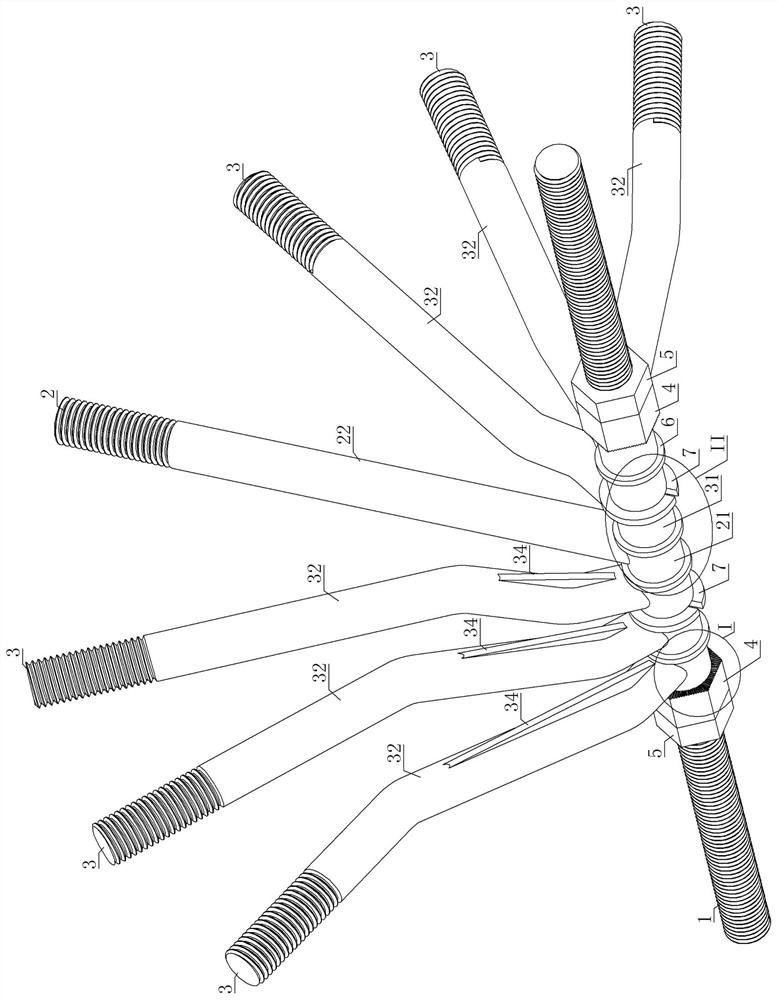

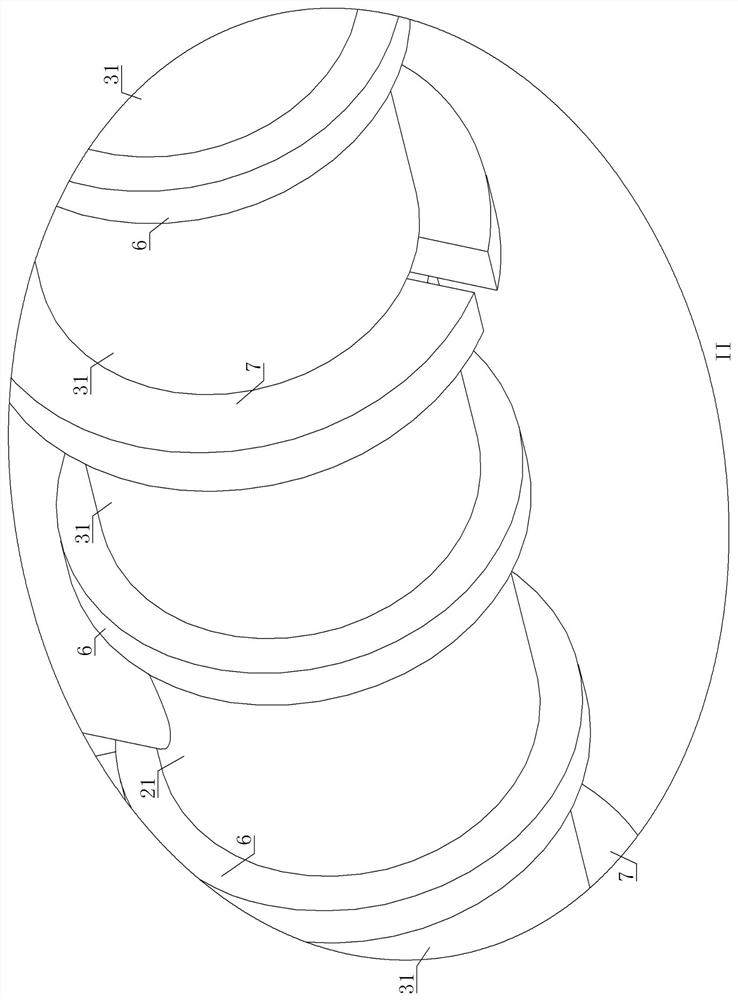

[0030] Embodiment one: see Figure 1-10 , a coplanar bar truss joint, including an adjusting screw, a middle member, two side members and a fixing nut;

[0031] The adjusting screw is set horizontally, and both ends are connected with other parts of the truss structure; the adjusting screw is equipped with middle rods, rods on both sides, and fixing nuts on both sides; the adjusting screw is all coplanar rod trusses. Node bearing parts;

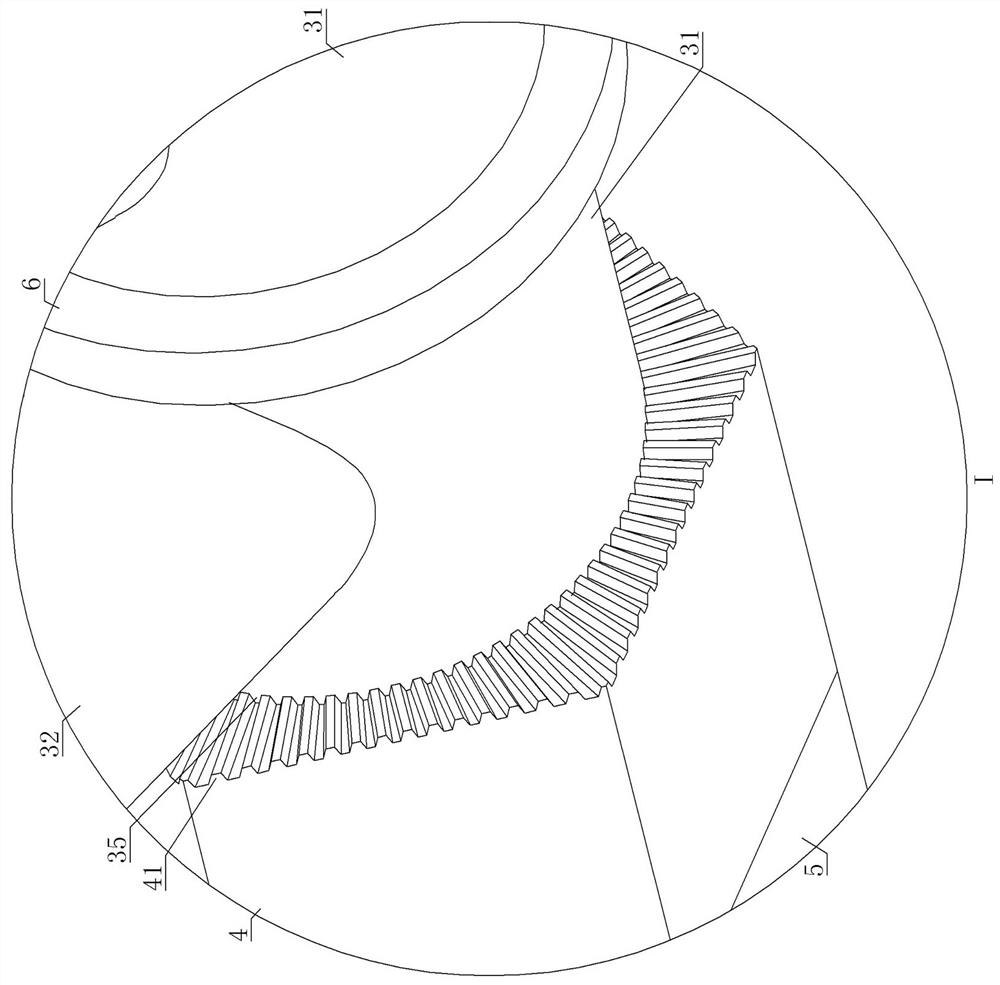

[0032] There is one middle rod, including the connected sleeve A and straight rod; the sleeve A slides and fits on the adjustment screw; one end of the straight rod is perpendicular to the sleeve A axis and is connected with the sleeve A, and the other end is connected with other parts of the truss structure connected; the middle rod is located in the middle of the coplanar rod truss node; the middle of the so-called coplanar rod truss node is not the center in the geometric sense, that is, the midpoint position of the adjustment screw, but ...

Embodiment 2

[0045] Embodiment two: refer to the appended Figure 1-5 , manual attached Figure 7-8 , manual attached Figure 10-12 , Embodiment 2 is basically the same as Embodiment 1, and the similarities will not be described in detail. The difference is that the thread profile of the external thread armor is smaller than the thread profile of the adjusting screw; the adjusting screw is a very important force-bearing part of the truss structure , The large tooth-shaped thread can ensure the mechanical strength of the adjusting screw; the external thread armor is only for the anti-loosening effect of the fixing nut, and does not require such a large mechanical strength.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com