Mine drainage pipe positioning and mounting equipment

A positioning installation and drainage pipe technology, which is applied in the direction of workpiece clamping devices, workbenches, manufacturing tools, etc., can solve the problems of increased difficulty in positioning, damage to waterproof coating, and difficult alignment of installation, so as to reduce deviation and reduce work The effect of prolonging the amount and duration of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

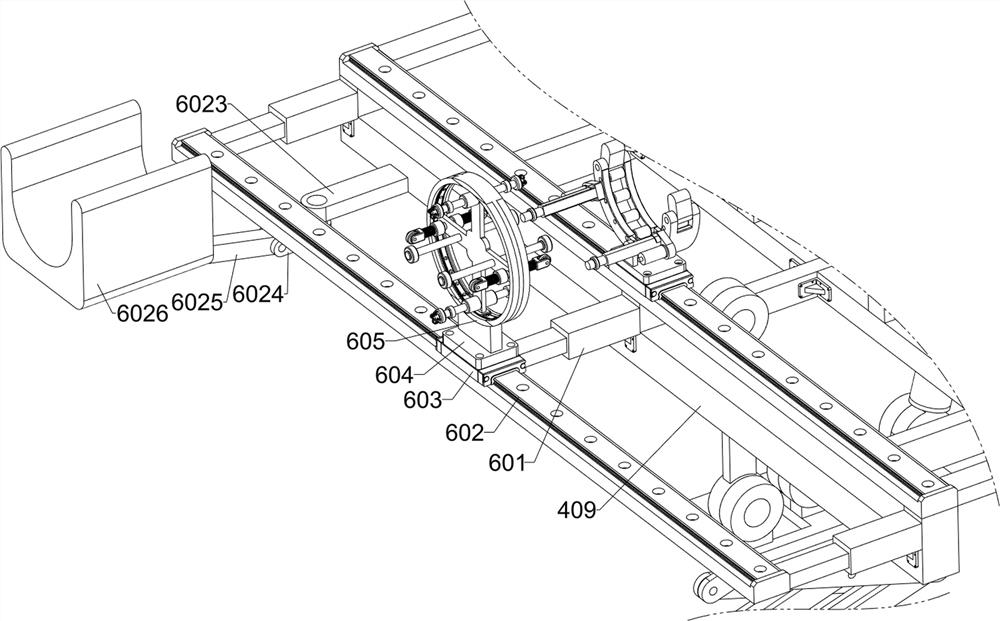

[0036] A mine drainage pipe positioning and installation equipment, such as Figure 1-11 As shown, it includes a wheel 1, a vehicle frame 2, a support base 3, an adjustment mechanism 4, a fixing mechanism 5 and a positioning mechanism 6; a vehicle frame 2 is installed between the four wheels 1; four supports are installed at the bottom of the vehicle frame 2 The base 3; the inner bottom of the frame 2 is equipped with an adjustment mechanism 4; the adjustment mechanism 4 is located between the four support bases 3; the upper part of the adjustment mechanism 4 is equipped with a fixing mechanism 5; the left part of the adjustment mechanism 4 is equipped with a positioning mechanism 6.

[0037] Working principle: first move the mine drainage pipe positioning and installation equipment to the mine where the drainage pipe needs to be installed, then control the mine drainage pipe positioning and installation equipment to run and debug through the built-in power supply, control the ...

Embodiment 2

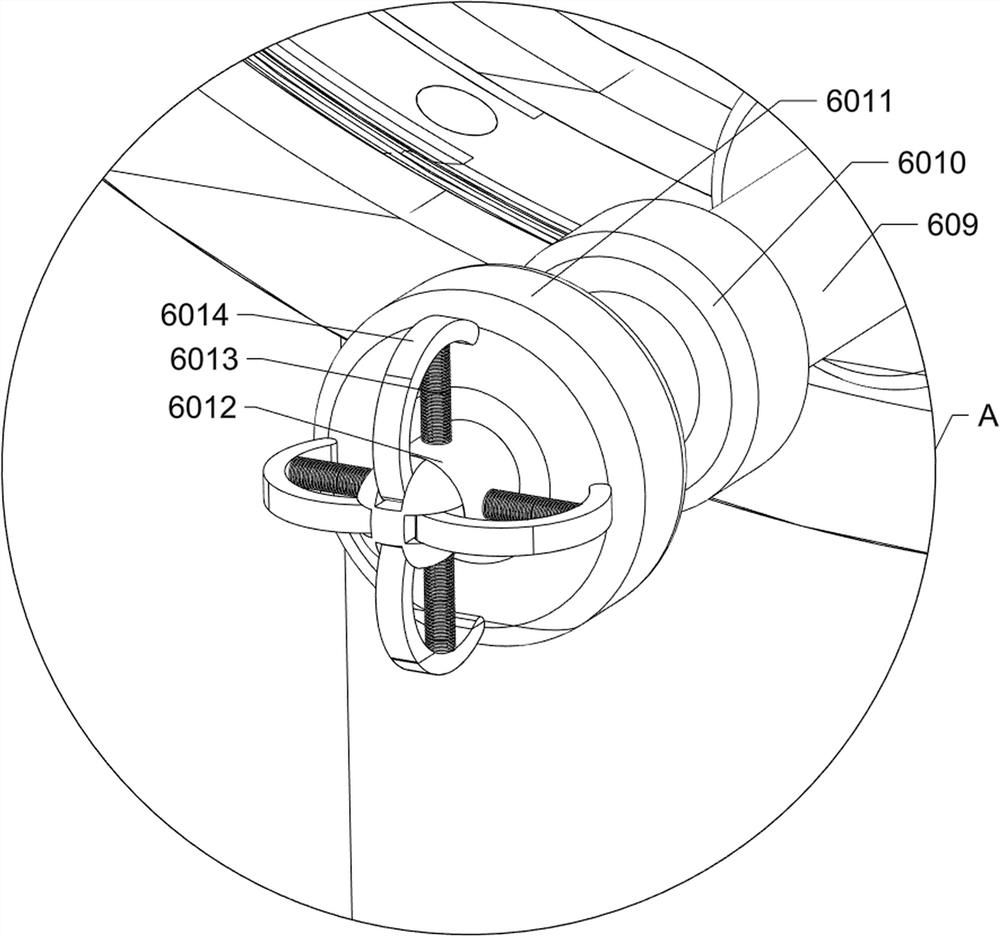

[0039] On the basis of Example 1, such as Figure 1-11 As shown, the adjustment mechanism 4 includes an electric turntable 401, a scissor frame 402, a first mounting plate 403, a first connecting plate 404, a first hydraulic push rod 405, a second hydraulic push rod 406, a second connecting plate 407, a first Three connecting plates 408 and brackets 409; the inner bottom of the vehicle frame 2 is fixedly connected with an electric turntable 401; the top of the electric turntable 401 is fixedly connected with a scissor frame 402; the top of the scissor frame 402 is fixedly connected with a first mounting plate 403; The left part of a mounting plate 403 is hinged with a first connecting plate 404; the middle part of the first mounting plate 403 is hinged with a first hydraulic push rod 405; the right part of the first mounting plate 403 is hinged with a second hydraulic push rod 406; The top of the hydraulic push rod 406 is hinged with a second connecting plate 407; the top of t...

Embodiment 3

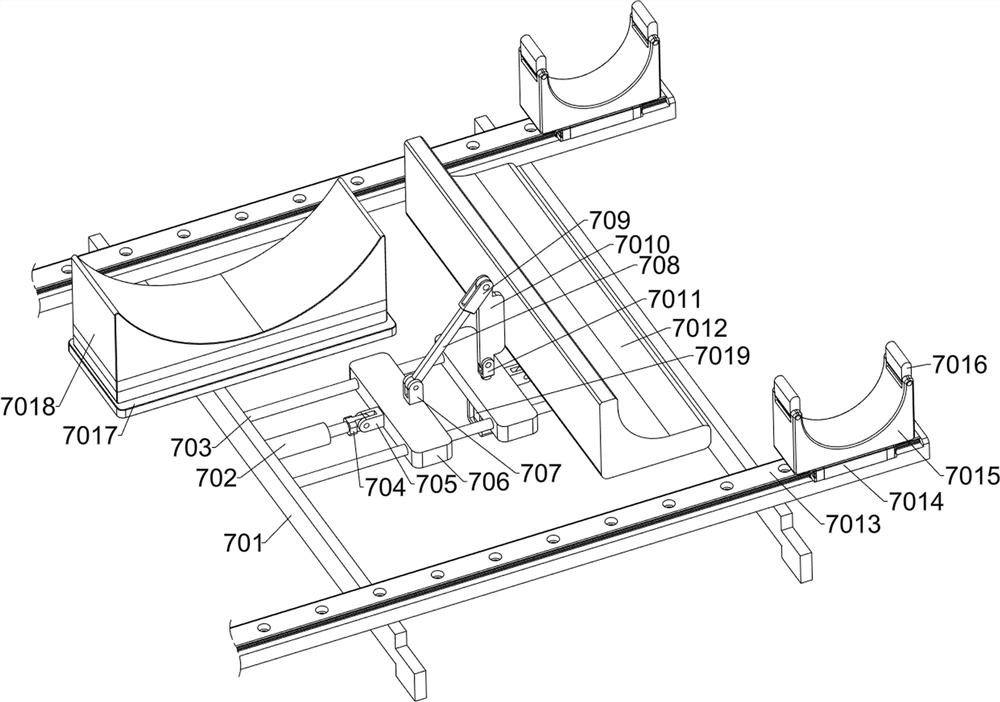

[0049] On the basis of Example 2, such as Figure 1-3 with Figure 12-14 As shown, a transportation mechanism 7 is also included; a transportation mechanism 7 is installed on the top of the adjustment mechanism 4; a transportation mechanism 7 is installed on the top of the fixing mechanism 5; the transportation mechanism 7 includes a seventh connecting plate 701, a second electric push rod 702, The second slide bar 703, the eighth connecting plate 704, the first bearing seat 705, the fourth slider 706, the second bearing seat 707, the ninth connecting plate 708, the third bearing seat 709, the tenth connecting plate 7010, the fourth Bearing seat 7011, L-shaped fixed seat 7012, fourth slide rail 7013, fifth slider 7014, second U-shaped fixed seat 7015, second limit block 7016, second mounting plate 7017, telescopic seat 7018 and third electric Push rod 7019; the upper part of the bracket 409 is fixedly connected with two seventh connecting plates 701; the upper part of the bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com