Intelligent warehouse control method and intelligent warehouse control system

A control method and warehouse technology, which is applied in transportation, packaging, storage devices, etc., can solve the problems of insufficient intelligence, slow inbound and outbound speed, etc., and achieve the effects of efficient transportation and good obstacle avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] like Figure 14 As shown, the embodiment of the present invention provides a smart warehouse control method, including the following steps:

[0070] Issue a transportation task, which includes the starting point, destination and transportation content;

[0071] Split the task instruction, determine the transportation direction as outbound transportation or inbound transportation according to the starting point and end point of transportation, split out the transportation task, determine the storage location or inbound storage location of the outbound material according to the transportation content, and split the outbound transportation Warehouse tasks;

[0072] Dispatch tasks, dispatch warehouse tasks to smart warehouses, find idle mobile robots, and designate one of the idle mobile robots to dispatch delivery tasks;

[0073] Path planning, obtaining the location of the smart warehouse and the transfer area, and planning the driving path of the mobile robot between t...

Embodiment 2

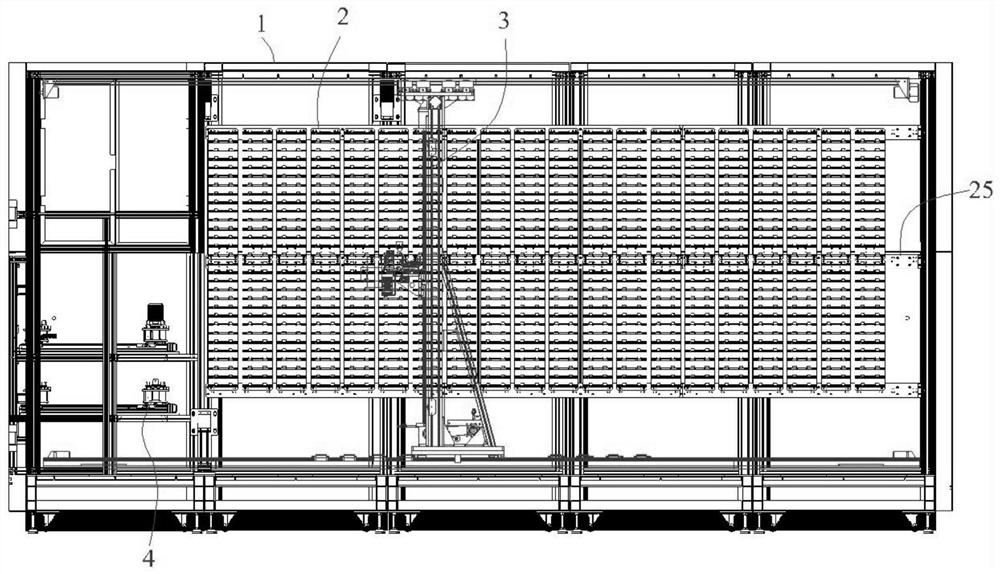

[0092] like figure 1 As shown, the present invention provides an intelligent warehouse including a warehouse body 1 , a storage rack 2 , a stacker 3 , and a transfer device 4 . Wherein, the warehouse body 1 is provided with a control device and is provided with a material port 113 for material storage and egress, and the warehouse body 1 is also provided with a rack area and a roadway arranged side by side with the rack area. The storage rack 2 is arranged in the material rack area for storing materials. The stacker 3 is arranged on the roadway and the control device is connected with electrical signals for storing and taking out materials. The transfer device 4 is arranged at the material port 113 and is electrically connected with the control device for transferring the material at the material port 113 to the stacker 3 or transferring the material on the stacker 3 to the material port 113 .

[0093] In this embodiment, when warehousing, the external transport device trans...

Embodiment 3

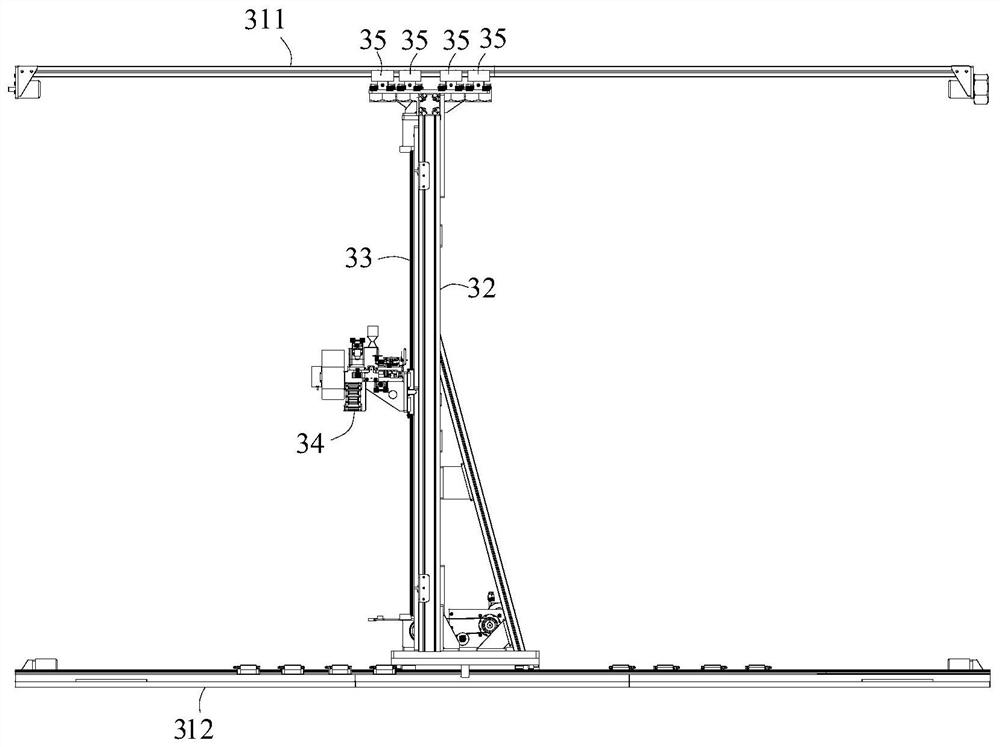

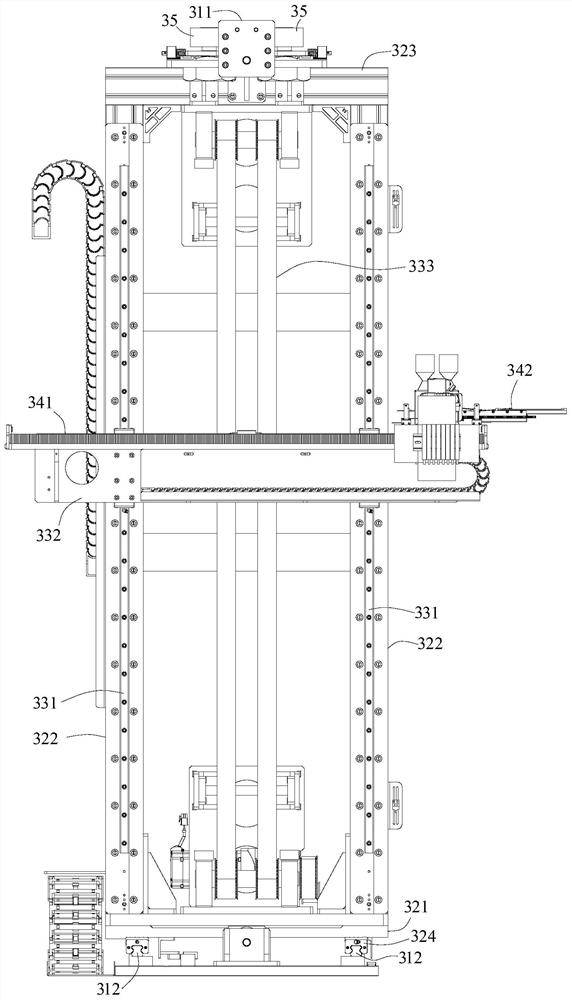

[0096] like Figures 2 to 12 As shown, the difference compared with Embodiment 1 and Embodiment 2 is that the stacker 3 includes an X-axis movement assembly, a bracket 32 , a lifting assembly 33 and a fork assembly 34 . The stacker 3 is applied to the stacker 3 moving in the roadway in the intelligent warehouse, and is used to pick and place the materials in the intelligent warehouse.

[0097] Specifically, as Figure 3 to Figure 5 As shown, the X-axis motion assembly includes an upper X-axis guide rail 311 and two lower X-axis guide rails 312, the upper X-axis guide rail 311 extends along the X-axis direction, the two lower X-axis guide rails 312 are arranged side by side at intervals, and the two lower X-axis guide rails 312 are arranged along the X-axis direction extends. The bracket 32 is arranged between the upper X-axis guide rail 311 and the lower X-axis guide rail 312 . The lifting assembly 33 is disposed on the bracket 32 and is used to drive the fork assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com