In-vitro pump-free tissue culture chip based on microfluidic technology

A microfluidic technology and tissue culture technology, applied in the field of in vitro pump-free tissue culture chips, can solve the problems of increasing the threshold of use and cost, and achieve the effect of convenient preparation and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

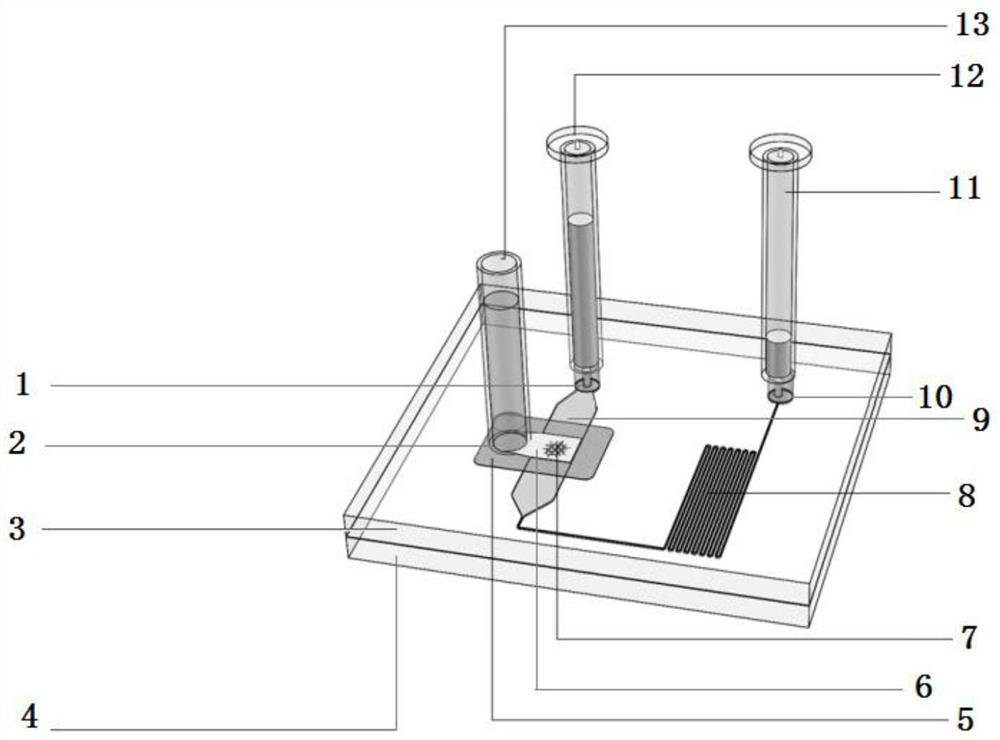

[0023] Such as figure 1 , the chip of this embodiment includes an upper chip 3 and a lower chip 4, and the upper chip 3 is arranged above the lower chip 4; the surface of the lower chip 4 is provided with a groove-shaped chamber passage 9, and the chamber passage One end of 9 is connected with the inlet 1, and the culture solution enters the chamber channel 9 through the inlet 1, and the other end of the chamber channel 9 is connected with one end of the groove-shaped flow resistance channel 8, and the other end of the flow resistance channel 8 is connected with the outlet 10 connected; the upper chip 3 is provided with a tissue chamber 6 for placing the sample 7, the tissue chamber 6 is provided with a sample loading port 2, and the tissue chamber 6 is arranged above the chamber channel 9, A porous membrane 5 is provided between the tissue chamber 6 and the chamber channel 9 to support the sample 7; above the upper chip 3, a culture medium collection pool 11, a culture medium...

Embodiment 2

[0033] The sample 7 described in this embodiment is a mouse testis tissue, and the steps are as follows: put the mouse testis tissue into the tissue chamber 6, and connect the culture medium storage solution at the inlet 1 and the outlet 10 The pool 12 is connected to the medium collection pool 11 , and the medium balance pool 13 is connected to the sample loading port 2 of the tissue chamber 6 . An appropriate amount of medium is added to the medium storage tank 12, and the medium can flow into the medium balance tank 13 and the medium collection tank 11 driven by gravity. The liquid level in the medium balance tank 13 will soon be the same as the medium storage tank 12 , and then the medium will slowly flow into the medium collection tank 11 . This method needs to regularly add medium to the medium storage tank 12 and discard the medium in the medium collection tank 11 .

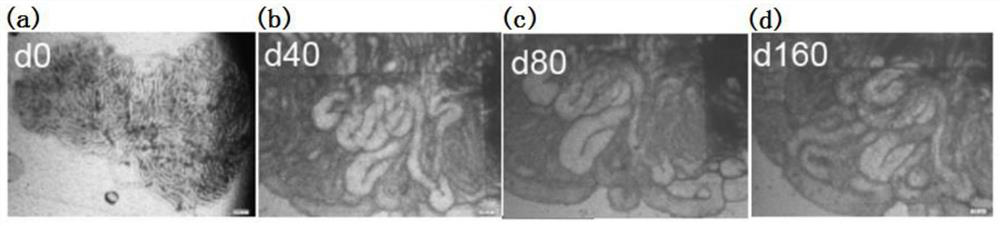

[0034] In 2011, Japanese scholar Takehiko Ogawa cultivated mouse testis tissue using an air-liquid int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com