Bamboo-wood structure beam column joint and method

A technology of beam-column joints, bamboo and wood, applied to building components, building structures, earthquake resistance, etc., can solve the problems of not improving the seismic capacity of beam-column joints, not satisfying strong joints and weak components, etc., so as to improve the connection firmness, Effect of improving connection performance and ensuring connection firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

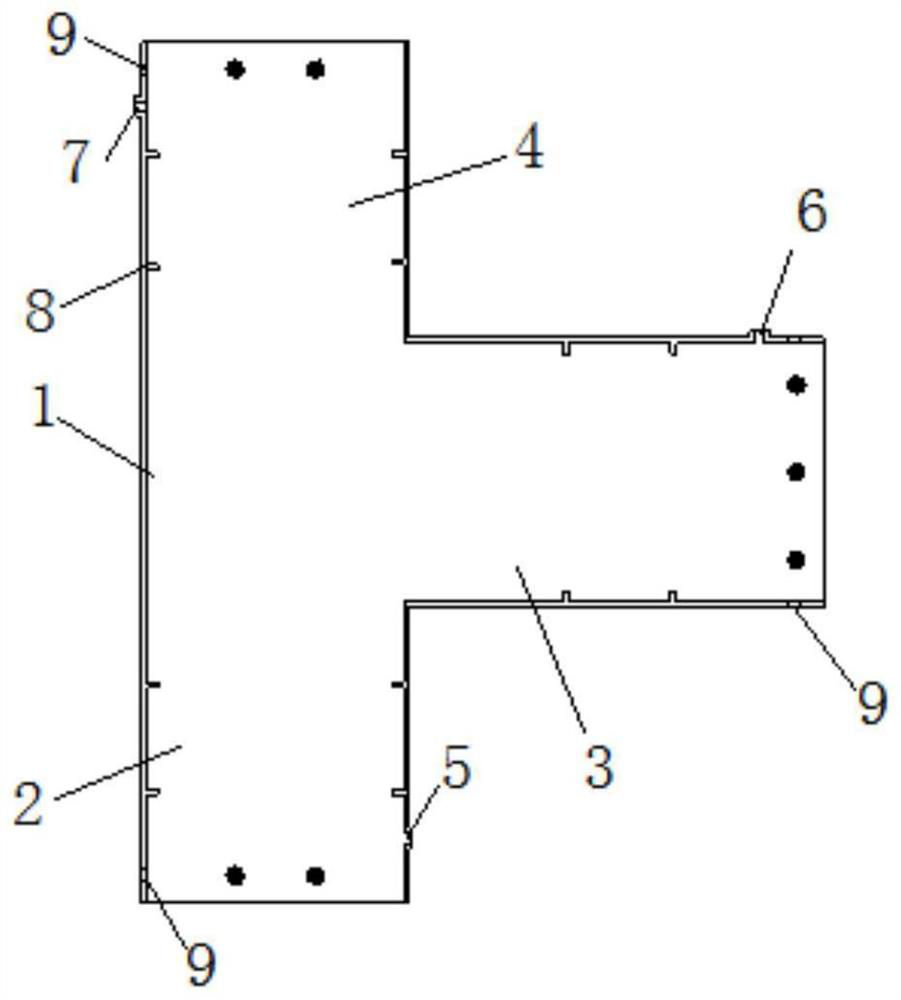

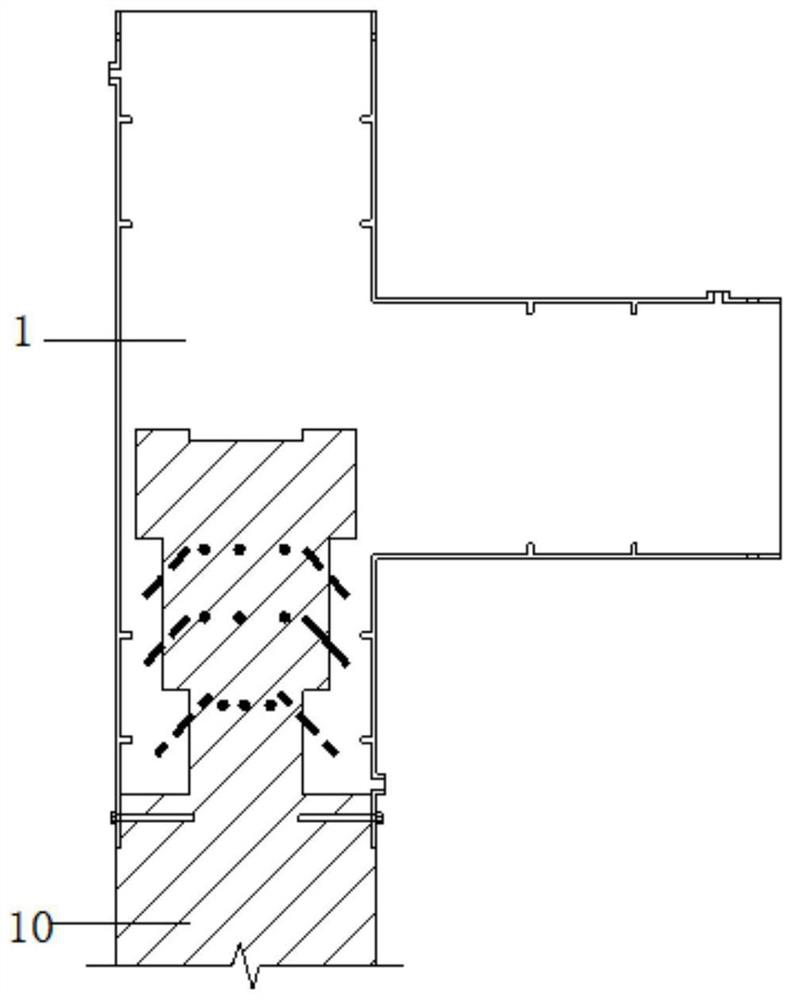

[0031] This embodiment provides a bamboo-wood structure beam-column node, including a node body 1, the node body 1 has at least two branches to connect different numbers of columns and beams; the branches are provided with interconnected passages, each passage The bamboo and wood components are installed, and the bamboo and wood components and the node main body 1 form a beam-column node.

[0032] Taking connecting the upper column, the lower column and the beam as an example, the corresponding node body 1 has three branches as an example, namely the first branch, the second branch and the third branch, and the three branches form a T-shaped structure; figure 1 As shown, a first channel 2 is provided in the first branch, a second channel 3 is provided in the second branch, and a third channel 4 is provided in the third branch.

[0033] In this embodiment, the node body 1 adopts a sleeve structure, such as a steel sleeve.

[0034] The inner walls of the first channel 2 , the s...

Embodiment 2

[0047] This embodiment provides a construction method for a beam-column joint of a bamboo-wood structure, comprising the following steps:

[0048] Step 1: Use 3D software (such as finite element software) to determine beam and column section dimensions according to actual needs.

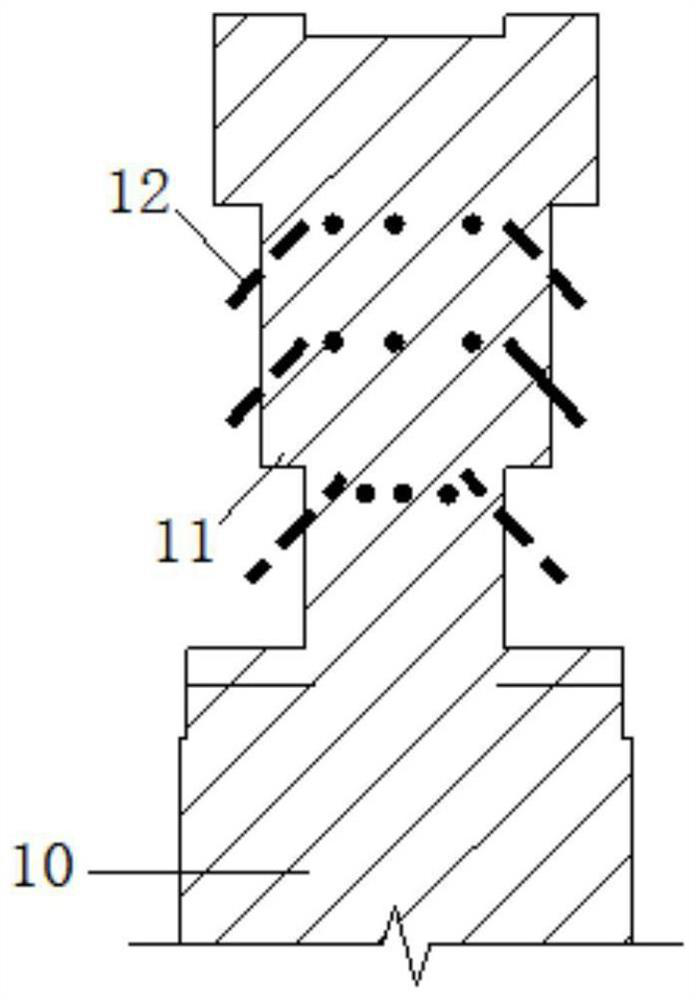

[0049] Step 2: Prefab as figure 2 For the bamboo and wood components shown, the bamboo and wood components can be machine-cut and made of tigers and buttresses through mold processing, and the angle between the inserted ribs and the bamboo and wood components is about 45°.

[0050] Wherein, the abutment is a section of the fitting part 11 away from the supporting part 10 .

[0051] Step 3: Insert each bamboo and wood member into the corresponding channel, and connect the upper column, lower column and beam with the node main body 1 through bolts.

[0052] Step 4: Pressure inject the grouting material from the grouting hole 5 until the grouting hole in the beam area (the first grouting hole 6) is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com