Building external wall thermal insulation and decoration integrated system

A technology for building exterior walls and thermal insulation boards, which is applied to buildings, building structures, floors, etc., can solve problems such as difficulty in fixing, inability to connect, and heat transfer coefficients that cannot meet the requirements of the area, and achieve improved heat transfer coefficients, Effects of enhanced connection performance and enhanced security performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

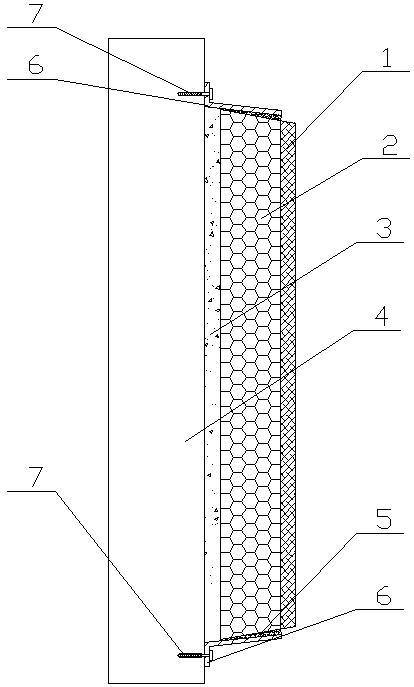

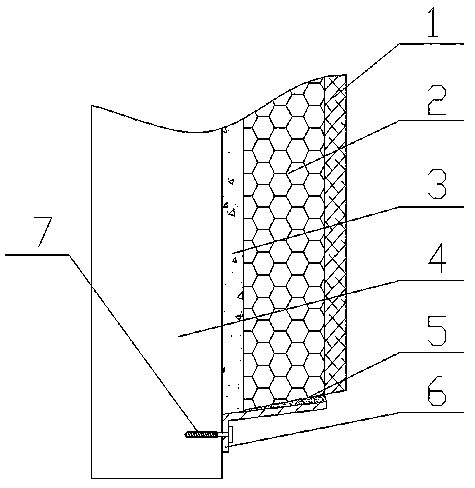

[0032] Embodiment one: see Figure 1 to Figure 6 , this embodiment provides an integrated system for thermal insulation and decoration of building exterior walls, comprising a glazed foamed ceramic thermal insulation board and a bonding mortar layer 3, the glazed foamed ceramic thermal insulation board includes a foamed ceramic thermal insulation layer 2 and a The glaze layer 1 formed by firing the foamed ceramic insulation layer at a high temperature once.

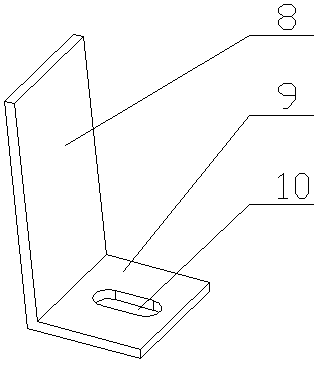

[0033] The upper and lower sides of the glazed foamed ceramic thermal insulation board are set as inclined surfaces, and the longitudinal section of the glazed foamed ceramic thermal insulation board is trapezoidal, and the cross section is rectangular or trapezoidal. The thermal insulation and decoration of the building exterior wall are integrated The system also includes at least two fasteners 6 respectively installed on the glazed foamed ceramic insulation board and the lower sides. The fasteners 6 include a fixed par...

Embodiment 2

[0037] Embodiment two: see Figure 4 to Figure 9 , this embodiment provides an integrated system for thermal insulation and decoration of building exterior walls, comprising a glazed foamed ceramic thermal insulation board and a bonding mortar layer 3, the glazed foamed ceramic thermal insulation board includes a foamed ceramic thermal insulation layer 2 and a The glaze layer 1 formed by firing the foamed ceramic insulation layer at a high temperature once.

[0038] The upper and lower sides of the glazed foamed ceramic thermal insulation board are set as inclined surfaces, and the longitudinal section of the glazed foamed ceramic thermal insulation board is trapezoidal, and the cross section is rectangular or trapezoidal. The thermal insulation and decoration of the building exterior wall are integrated The system also includes at least two fasteners 6 respectively installed on the glazed foamed ceramic insulation board and the lower sides. The fasteners 6 include a fixed par...

Embodiment 3

[0042] Embodiment 3: This embodiment provides an integrated system for thermal insulation and decoration of building exterior walls, including a composite thermal insulation board and a bonded mortar layer 3. The composite thermal insulation board includes a glazed foamed ceramic thermal insulation board and a second thermal insulation board 12 And the second adhesive layer 13 for bonding the glazed foamed ceramic insulation board and the second insulation layer, the glazed foamed ceramic insulation board includes the foamed ceramic insulation layer 2 and the primary high temperature with the foamed ceramic insulation layer Glazed layer 1 formed by sintering.

[0043] The upper and lower sides of the glazed foamed ceramic thermal insulation board are set as inclined surfaces, and the longitudinal section of the glazed foamed ceramic thermal insulation board is trapezoidal, and the cross section is rectangular or trapezoidal. The thermal insulation and decoration of the building...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com