Pneumatic tire

A technology of pneumatic tires and tire circumferential direction, which is applied to the reinforcement layer of pneumatic tires, special tires, tire parts, etc. The effect of durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

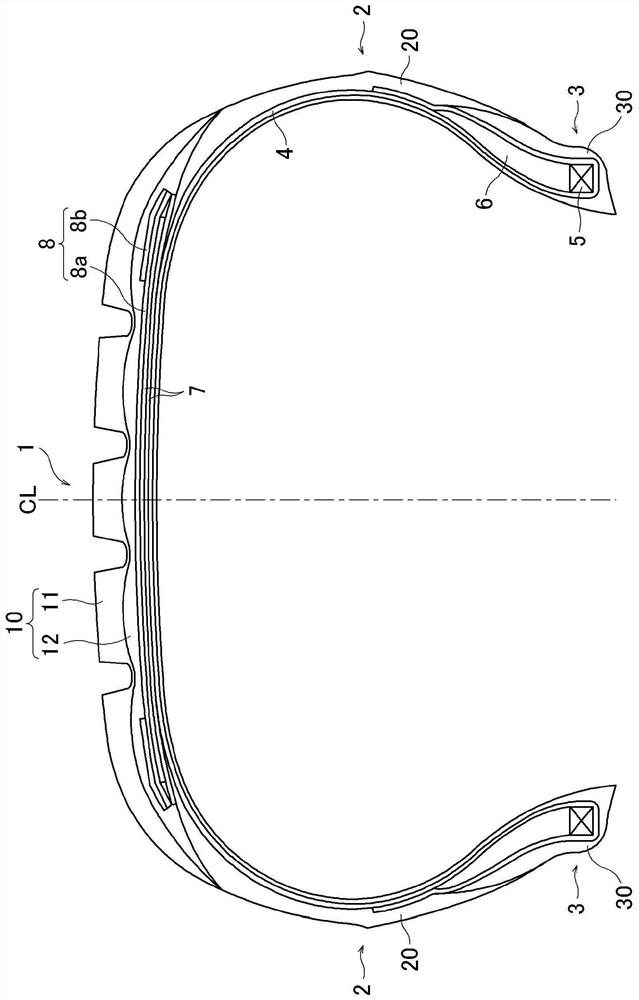

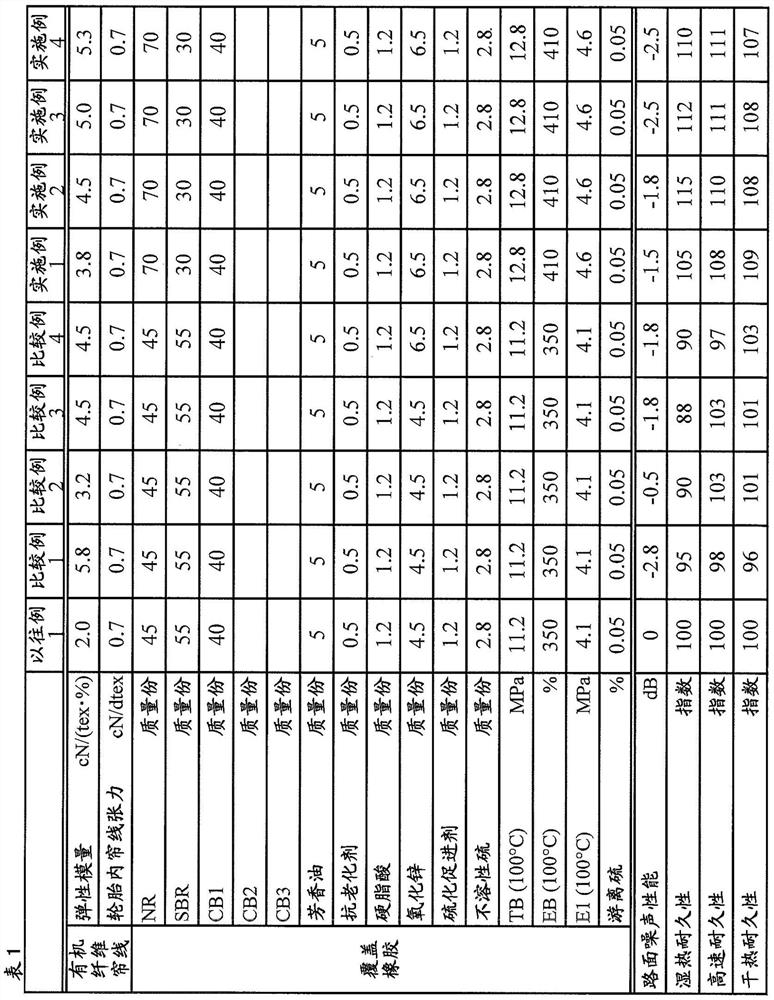

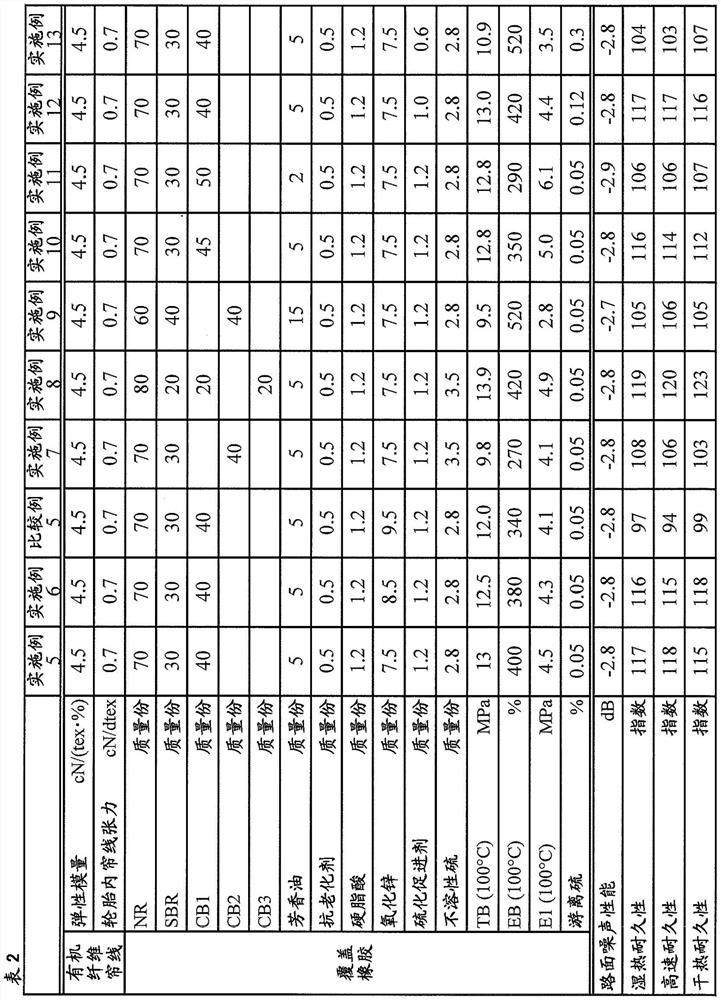

[0041] The tire size is 225 / 60R18, with figure 1 For the illustrated basic structure and the organic fiber cord (PET fiber cord) constituting the belt cover layer, the modulus of elasticity under a load of 2.0 cN / dtex at 100°C was set as described in Tables 1 and 2 [ cN / (tex·%)], the cord tension in the tire [cN / dtex], and for the covering rubber (belt cover covering rubber) covering the organic fiber cord (PET fiber cord), Table 1 The blending of the rubber composition constituting the covering rubber as described in ~2, the breaking strength at 100°C TB (100°C) [MPa], the elongation at break at 100°C EB (100°C) [%], and the 100°C Tires of Conventional Example 1, Comparative Examples 1 to 5, and Examples 1 to 13 having different storage elastic modulus E1 (100° C.) [MPa] and free sulfur ratio [%].

[0042] In either case, the belt cover layer has a belt formed by aligning one organic fiber cord (PET fiber cord) and covering it with a covering rubber, and is wound spirally in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com