Feces collecting box sliding mechanism of cattle farm feces cleaning vehicle

A feces collection box and excrement cleaning technology, which is applied in animal houses, applications, animal husbandry, etc., can solve the problems of cumbersome operation, many procedures, and high failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

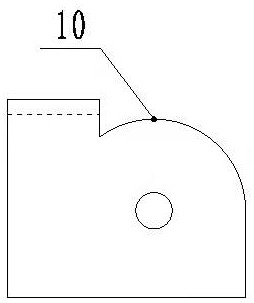

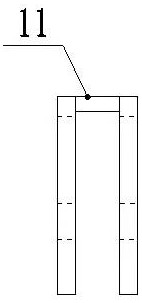

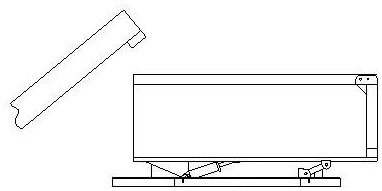

[0016] A sliding mechanism for a manure collection box in a cattle farm, consisting of a frame (1), an elevator (2), a manure collection box (3), a rear limiter (4), a swing arm (5), and a front limiter (6), lifting cylinder (7), lower slider (8), upper slider (9), hinged ear (10), baffle plate (11).

[0017] When working, the excrement truck is transported to the designated place, and the sliding mechanism of the excrement box is as follows: figure 1 state, the elevator (2) first lifts the feces and drops them to the feces collection tank (3), then starts the lifting cylinder (7), and moves the upper slider (9) backward and forward along the lower slider (8) Slide down, and at the same time, the two swing arms (5) rotate clockwise. When the two swing arms (5) rotate to coincide with the upper slope of the rear limit block (4), the upper slider (9) and the lower slider ( The slopes of 8) are also completely overlapped, and the two swing arms (5) are restricted by the rear li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com