Soybean milk machine

A soymilk machine and machine head technology, applied in the field of food processing, can solve problems such as burns, reduce user experience, and difficult to clean sanitary protective covers, achieve the effects of easier cleaning and reduce the risk of scalding users

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

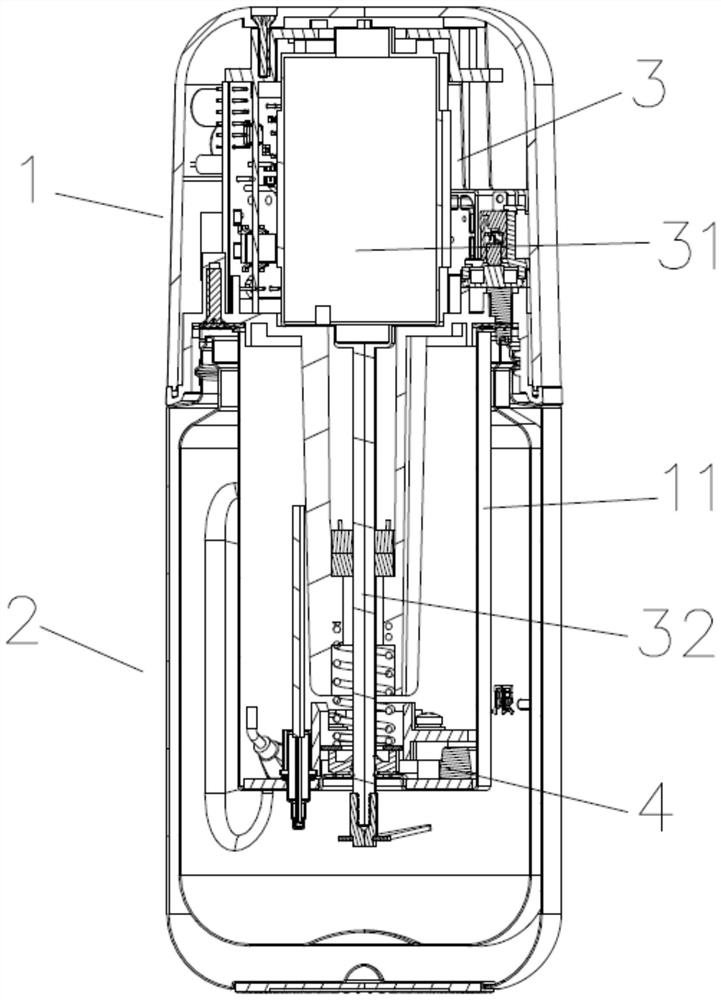

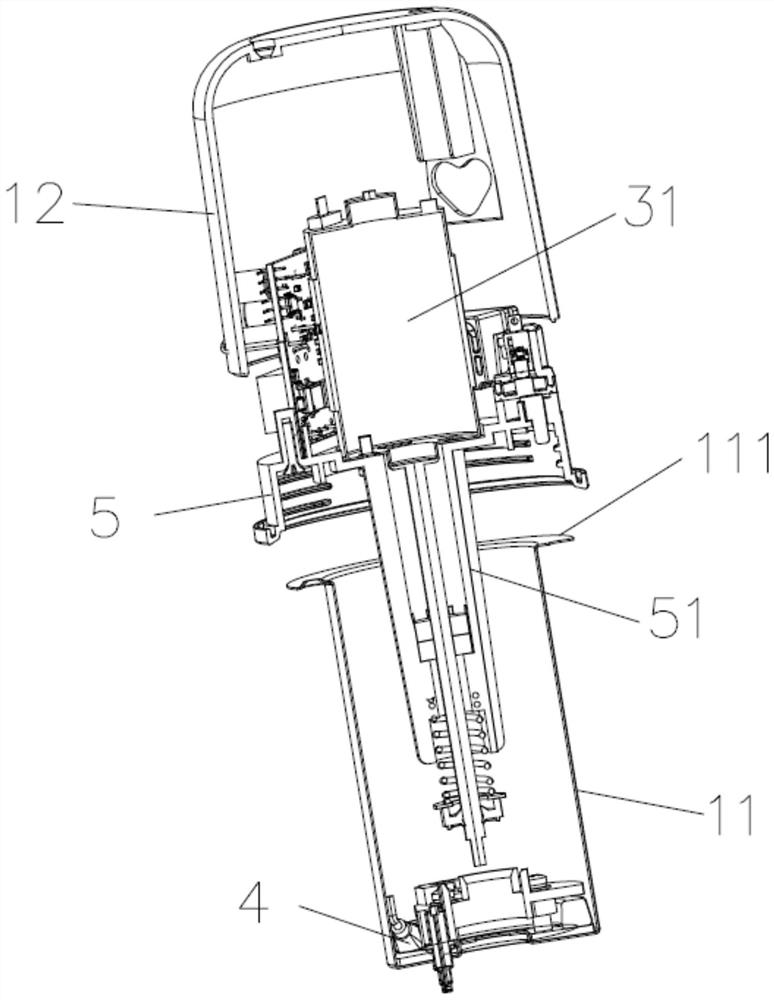

[0024] The soybean milk machine that the embodiment of the present invention provides, such as Figure 1 to Figure 2 As shown, it includes a machine head 1 and a cup body 2, the cup body 2 has a cup mouth, the machine head 1 is covered at the cup mouth, the machine head 1 is provided with a motor 3, and the motor 3 Including a motor body 31 and a rotating shaft 32, the end of the rotating shaft 32 is provided with a crushing device, and it is characterized in that: the machine head 1 has a heat conducting cylinder 11 extending into the mouth of the cup, and a heating device is provided in the heat conducting cylinder 11 4. The heating device 4 is located at the lower part of the heat conducting cylinder 11, and the motor body 31 is located above the mouth of the cup.

[0025] In the soymilk machine provided by the embodiment of the present invention, the heat conduction cylinder extends into the cup body, the heating device is located in the heat conduction cylinder, and the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com