Active and passive integrated self-ligating bracket

A self-locking bracket, active and passive technology, applied in brackets, arch wires, etc., can solve the problems of not easy to fix, lock, pull off, etc., and achieve the effect of not easy to fall off, stable installation, and hard to fall.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

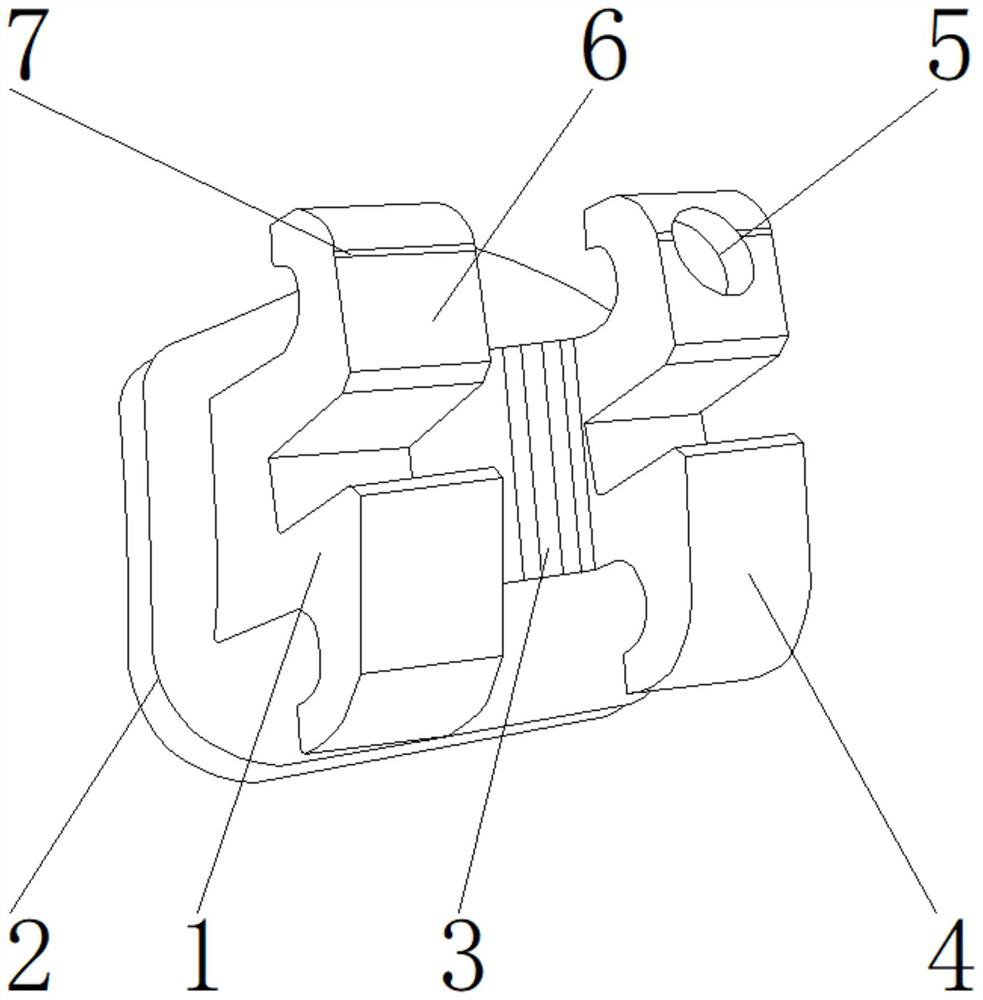

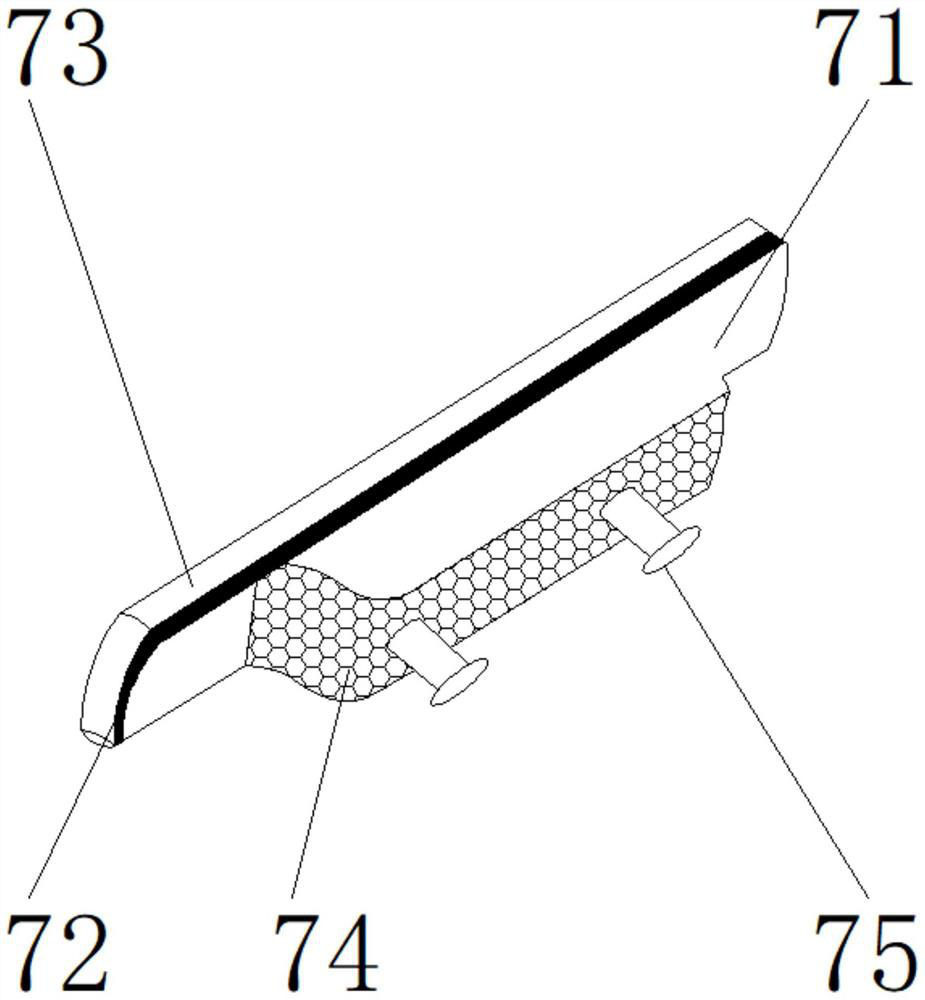

[0029] Such as Figure 1-5 As shown, the present invention provides an active and passive integrated self-locking bracket, comprising a main body 1, a base plate 2 is arranged at the lower end of the main body 1, a bracket body 6 is arranged at the upper end of the main body 1, and one side of the bracket body 6 is arranged There is a locking device 7, one side of the main body 1 is provided with an auxiliary device 3, one side of the auxiliary device 3 is provided with an elastic assembly 4, and the rear end of the elastic assembly 4 is provided with a fixing hole 5; the locking device 7 includes a locking plate 71, Adhesive strip 72, mounting plate 73, anti-corrosion coating 74, miniature screw 75, viscous strip 72 is positioned at the front end of mounting plate 73, and locking plate 71 is positioned at the front end of viscous strip 72; Between locking plate 71 and viscous strip 72 Superglue is provided, and the front end of the viscous strip 72 is fixedly connected to the...

Embodiment 2

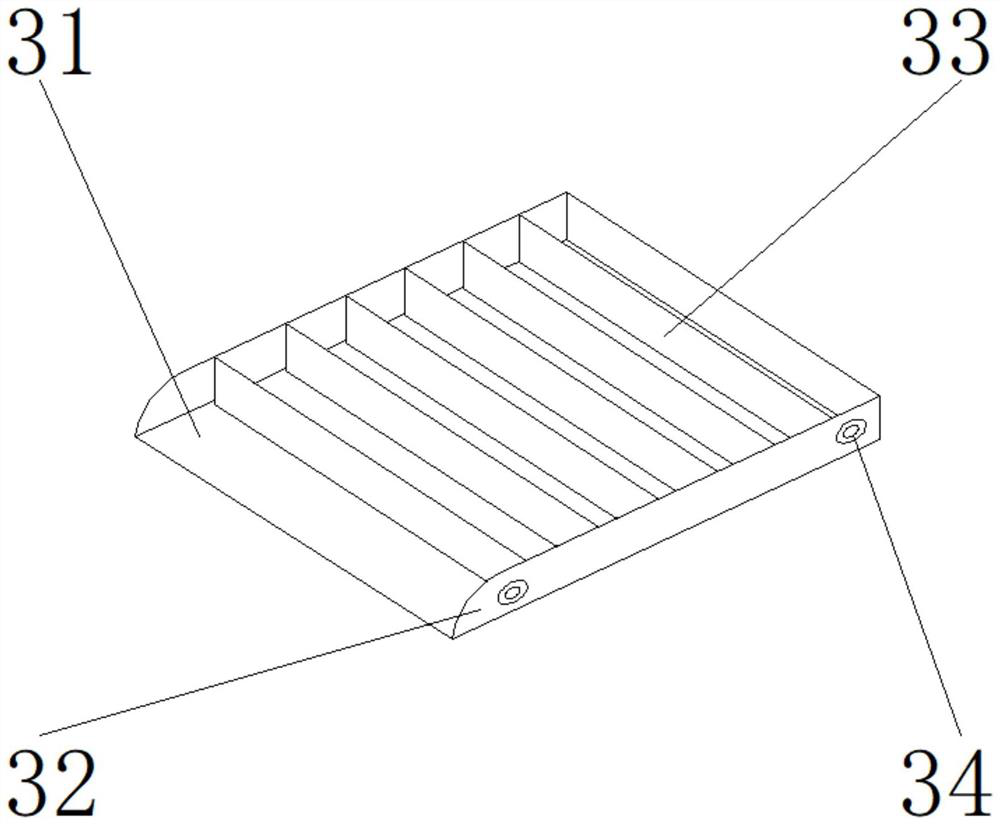

[0032] Such as Figure 1-5 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the auxiliary device 3 includes an arch wire slot 31, a side plate 32, an engaging mechanism 33, and a reed 34, and the engaging mechanism 33 is located on the arch wire. The upper end of the wire slot 31, the side plate 32 is located on both sides of the arch wire slot 31, the reed 34 is located on the outer surface of one side of the side plate 32, there is only a notch between the arch wire slot 31 and the engaging mechanism 33, the arch wire slot The upper end of 31 is detachably connected to the lower end of the engaging mechanism 33 through a notch, and a welding block is arranged between the side plate 32 and the arch wire slot 31, and one side of the side plate 32 is fixed to both sides of the arch wire slot 31 by the welding block To connect, a through hole is provided between the side plate 32 and the reed 34 , and one side of the reed 3...

Embodiment 3

[0035] Such as Figure 1-5As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the engaging mechanism 33 includes an engaging plate 331, a guide bevel 332, a limit bar 333, a connecting hole 334, a buckle plate 335, and a guide The hypotenuse 332 is positioned at the rear end of the clamping plate 331, the buckle plate 335 is positioned at the front end of the clamping plate 331, the connection hole 334 is positioned at one side of the buckle plate 335, the limit bar 333 is positioned at one side of the clamping plate 331, and the clamping plate 331 and the guide inclined A welding block is arranged between the sides 332, and the front end of the guide hypotenuse 332 is fixedly connected with the rear end of the engaging plate 331 through the welding block, and a fixing bolt is arranged between the engaging plate 331 and the buckle plate 335, and the front end of the engaging plate 331 passes through the fixing bolt. It is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com