Pipe rail bridging type mechanism of production line

A bridging, production line technology, applied in conveyor objects, conveyor control devices, lifting devices, etc., can solve the problems of reducing the operation efficiency and slow speed of large-scale processing and production equipment, and achieve the effect of reduced consumption and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

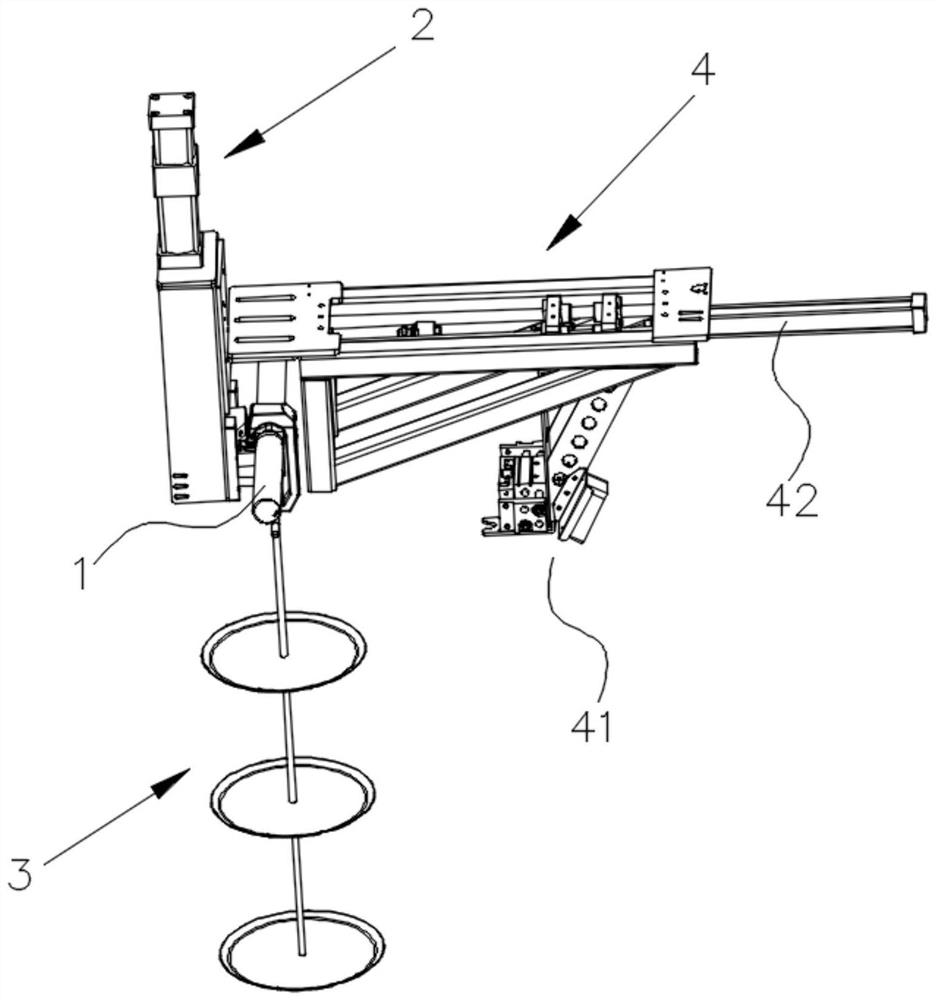

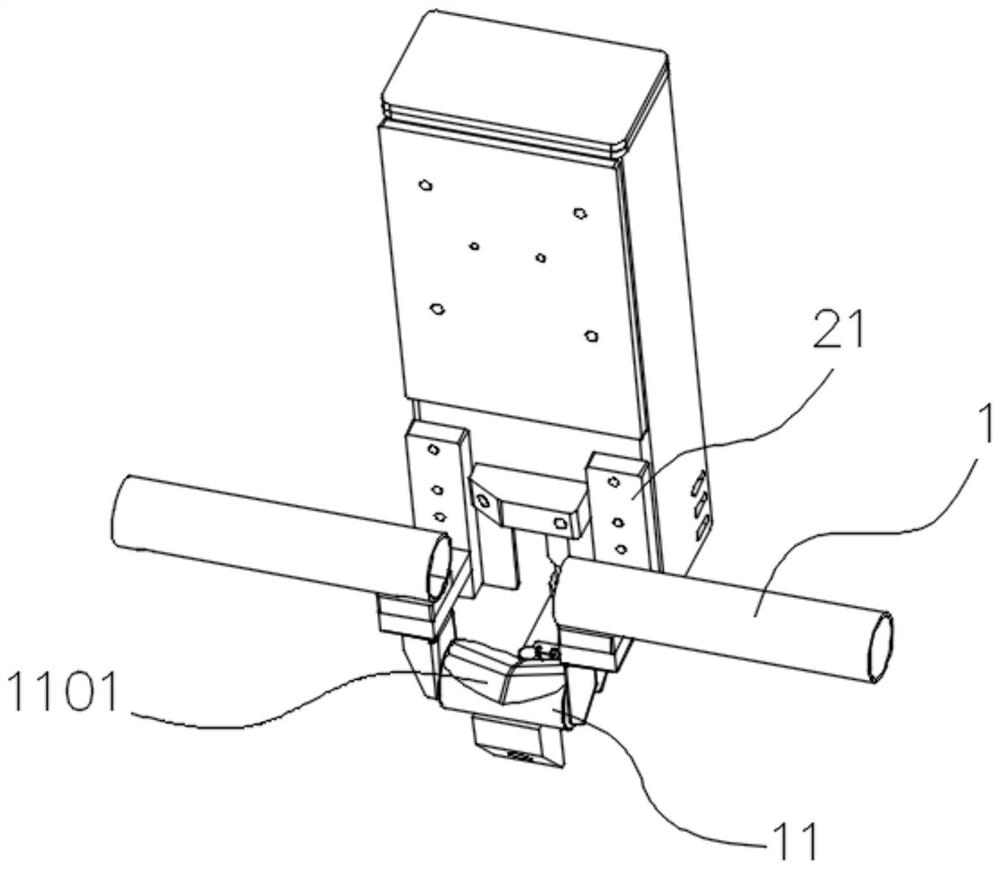

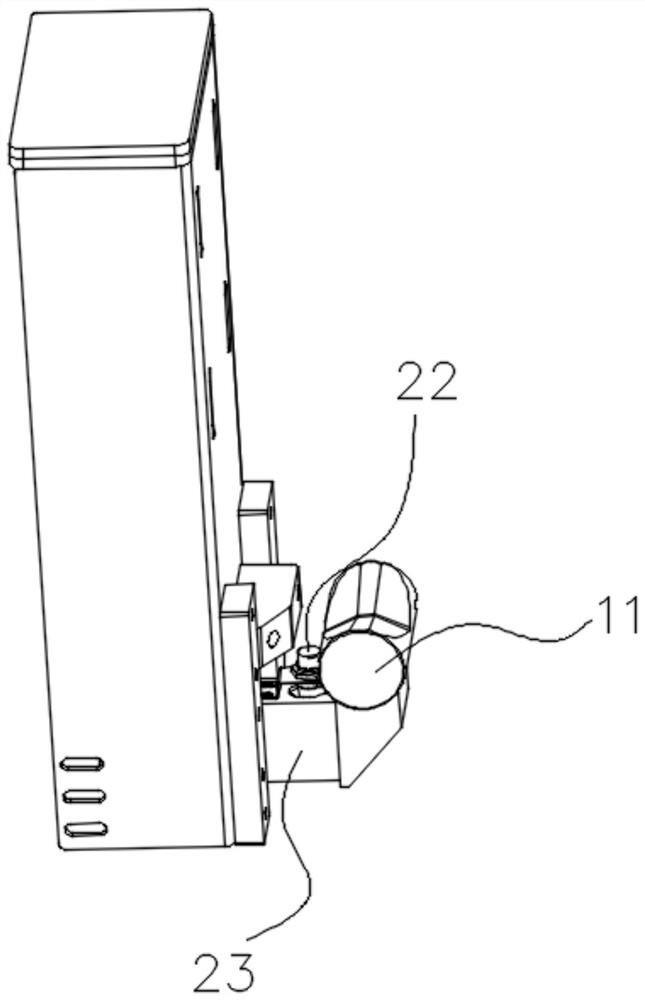

[0024] Attached below Figures 1 to 7 The present invention will be described in detail.

[0025] A pipe-rail bridging mechanism of a production line according to the present invention includes a plurality of fixed pipe rails 1 arranged in sequence, gaps are arranged between the fixed pipe rails 1, load-bearing blocks 11 are arranged in the gaps, and lifting devices 2 are included. The lifting device 2 can drive the load-bearing block 11 to move up and down; it also includes a loading device 3 and a shipping device 4, and the loading device 3 is provided with a hook 31 that can be hung on the fixed pipe rail 1 to move, and the shipping device 4 A load-bearing platform 41 capable of carrying the loading device 3 and a power device 42 for driving the load-bearing platform 41 to move are provided. In the technical solution of the present invention, the overall equipment of the production line has a plurality of operating stations, and each operating station has a load-bearing bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com