Wide-width low-gram-weight paper roll dividing method and device

A paper roll and wide-width technology, which is applied in the field of unwinding device and wide-width low-weight paper, can solve the problems of paper breakage, pleating, and inappropriate angles, and achieve the effect of improving the efficiency of the unwinding work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

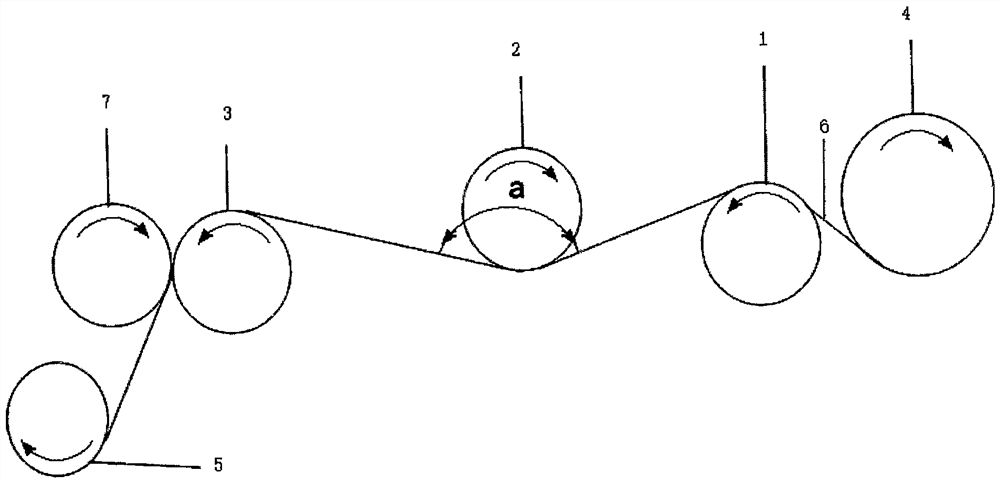

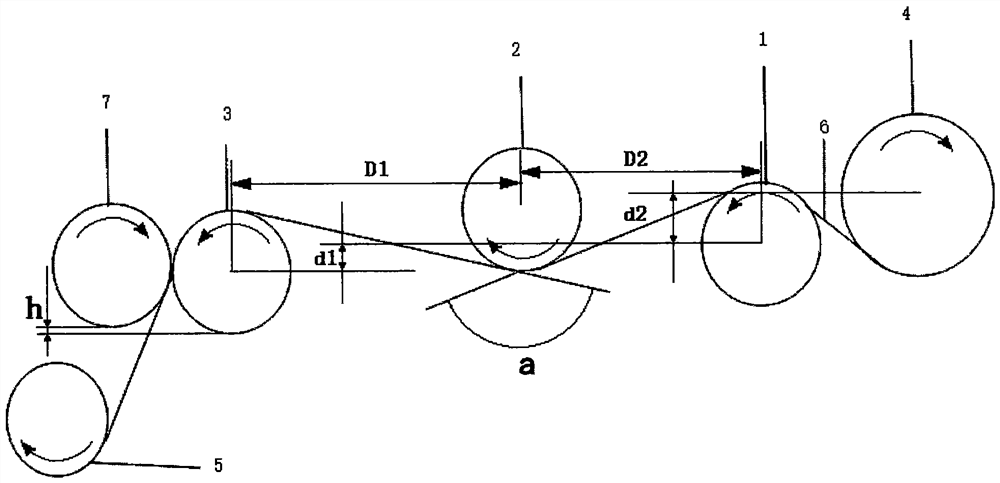

[0042] Such as figure 1 with figure 2 In the shown embodiment, a kind of wide and low grammage paper reeling device comprises a frame (not shown in the figure), is provided with base paper reel 4 and paper separation reel 5 on this frame, base paper Roller 4 and paper-splitting roll 5 are connected to the driving device to make it rotate to roll the paper tape 6 on the base paper roll onto the paper-separating roll 5 to achieve the purpose of splitting. The width of the paper tape is between 2.1- Between 2.6 meters, the weight is 30-55 grams / meter 2 .

[0043]A paper tape adjustment device is arranged between the base paper roll 4 and the paper separation roll 5, and the paper tape adjustment device includes base paper roll unwinding rollers arranged in sequence from the base paper roll 4 to the separation paper roll 5 arranged on the frame 1. The fixed angle roller 2 and the running paper rewinding roller 3, the axis of the base paper roll 4 is higher than the axis of the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap