Damage-resistant high-brightness reflective glass bead and preparation method thereof

A glass bead and high-brightness technology, applied in the field of reflective optical materials, can solve the problems of poor durability of retroreflective brightness, impact resistance, friction resistance, poor water resistance and environmental pollution resistance, durability, environmental pollution resistance and wear resistance Insufficient and other problems, to achieve the effect of high-brightness reflective performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] Examples Mass or mass ratio.

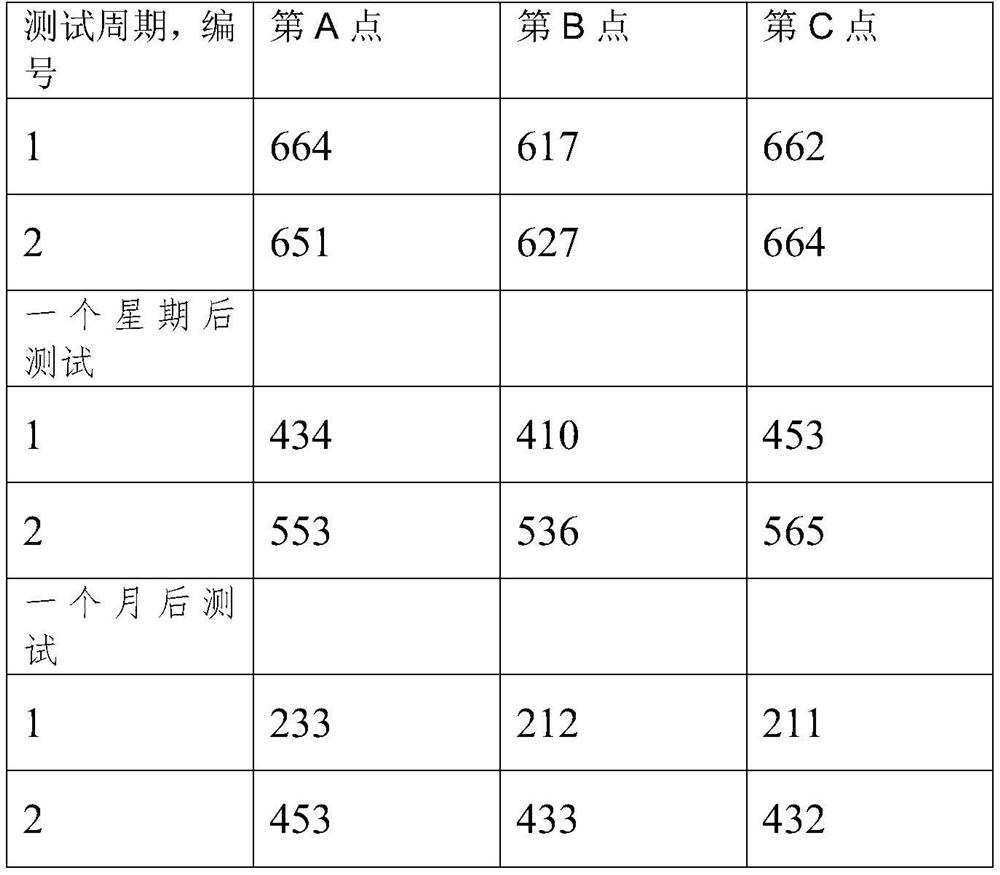

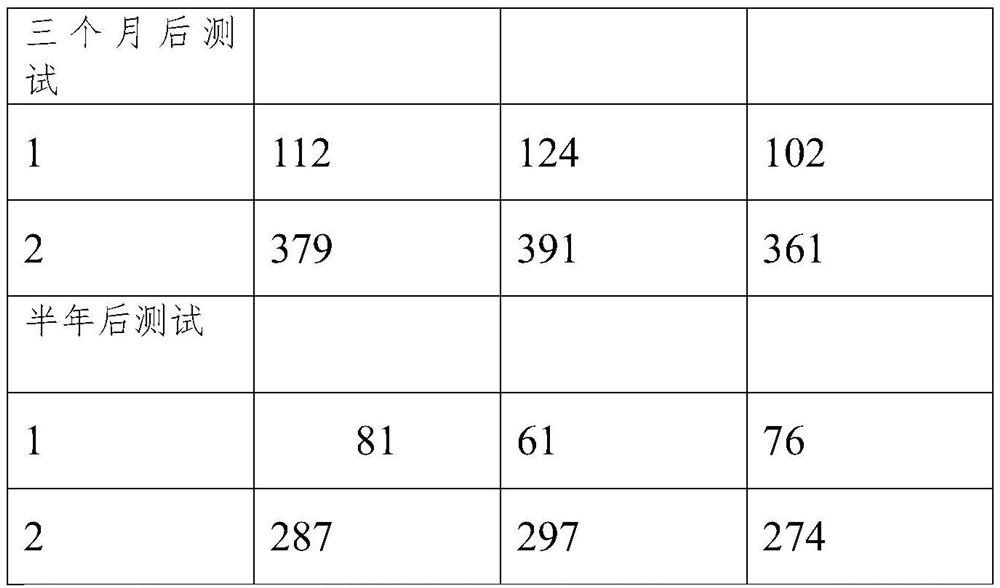

[0041] Table 2

[0042]

[0043]

[0044]

[0045]

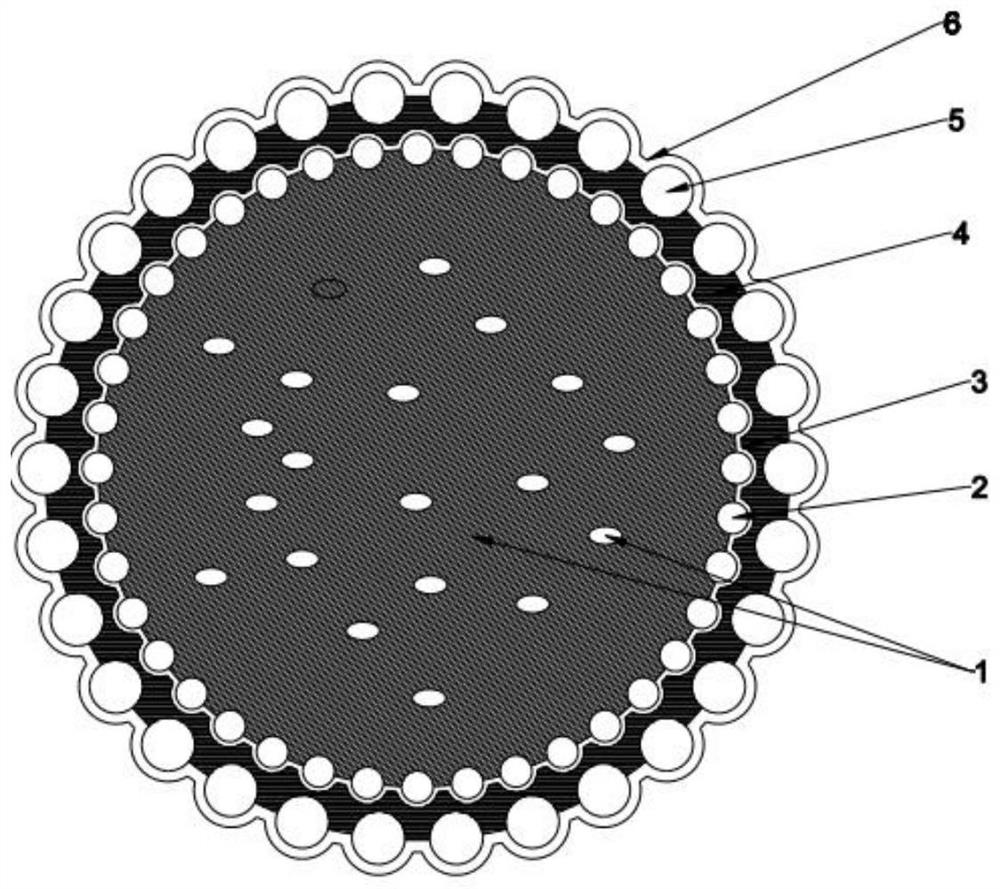

[0046] Explanation: The composition of each component in the above examples can be obtained from the market. The moisture-curable silicone resin and moisture-curable polyurethane resin as described in the present invention refer to curable silicone resin and curable polyurethane resin. Utilize the above-mentioned table 2 embodiment of the present invention, prepare according to the following preparation method, specifically the forming of the elastic bubble inner core 1 → the elastic bubble inner core is stirred and thermally coated with the glass microsphere layer → the inner glass microsphere is bonded to the protective layer Stirring coating→stirring coating of glass bead bonding reflective layer outsourcing→glass bead bonding reflective layer stirring heat coating glass bead layer→stirring coating of anti-fouling and wear-resistant layer, then aging→anti-damage high brig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com