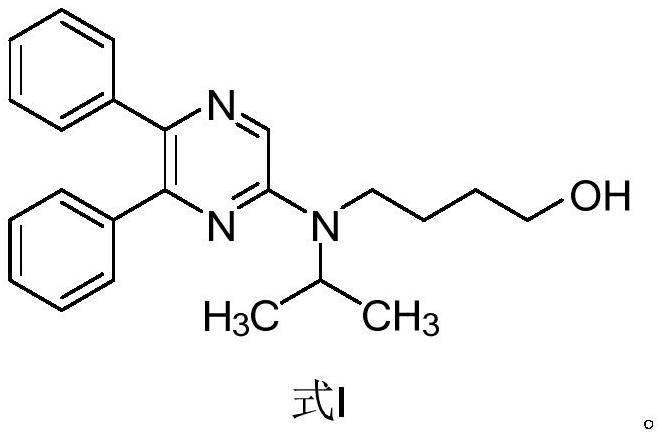

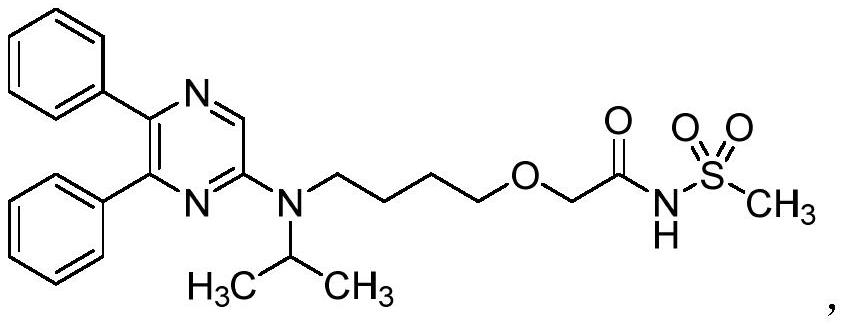

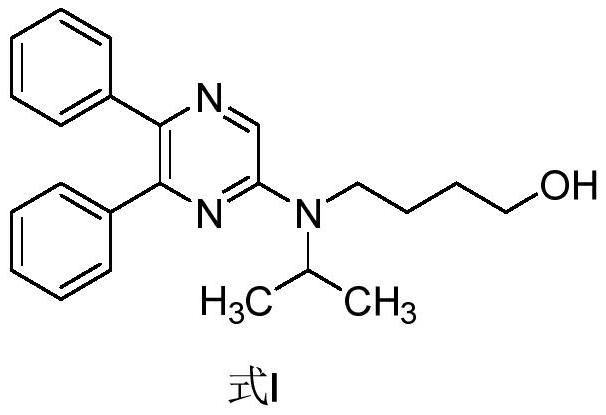

Method for preparing and purifying selexipag intermediate

A technology of Selensipa and purification method, which is applied in the field of preparation and purification of Selexipah intermediates, can solve the problems of long operation time, reduced product purity, unsatisfactory yield, etc., and achieve refined purity and product yield. High efficiency, improve the purity and yield, improve the effect of product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] To 1 L N-methylpyrrolidone, 5-chloro-2,3-diphenylpyrazine (100 g, 0.375 mol) butanol (150 g, 1.145 mol) was added to the 1L N-methylpyrrolidone. ), The temperature rose to 170-180 ° C for 20-25 hours. The TLC was stopped after the reaction was completely stopped, and the reaction solution was cooled to room temperature. 500 ml of isopropyl alcohol was added to the reaction mixture, and 2.5 L purified water stirred is added dropwise. Filtration, sampling feed phase purity 98.8%. The filter cake was dissolved with 300 ml of dichloromethane, and 1.5L n-hexane stirred was added dropwise. After filtration, the filter cake was dried under vacuum, 96.5 g of light yellow solid, yield was 71.2%, and the liquid phase purity was 99.3%.

Embodiment 2

[0055] To 1 L N-methylpyrrolidone, 5-chloro-2,3-diphenylpyrazine (100 g, 0.375 mol) butanol (150 g, 1.145 mol) was added to the 1L N-methylpyrrolidone. ), The temperature rose to 170-180 ° C for 20-25 hours. The TLC was stopped after the reaction was completely stopped, and the reaction solution was cooled to room temperature. 600 ml of acetone was added to the reaction mixture, and a 3l purified water mixture was added dropwise. Filter, sampling the test liquid phase purity 99.0%. The filter cake was dissolved with 300 ml of dichloromethane, and 1.5L n-hexane stirred was added dropwise. After filtration, the filter cake was dried under vacuum, 95.4 g of light yellow solid, yield 70.4%, and the liquid phase purity was 99.4%.

Embodiment 3

[0057] To 1 L N-methylpyrrolidone, 5-chloro-2,3-diphenylpyrazine (100 g, 0.375 mol) butanol (150 g, 1.145 mol) was added to the 1L N-methylpyrrolidone. ), The temperature rose to 170-180 ° C for 20-25 hours. The TLC was stopped after the reaction was completely stopped, and the reaction solution was cooled to room temperature. 500 ml of acetone was added to the reaction mixture, and 2.5 L purified water stirlated was added dropwise. Filtration, sampling the test liquid phase purity 98.9%. The filter cake was dissolved with ethyl acetate, and 2 l of n-hexane stirred was added dropwise. After filtration, the filter cake was dried under vacuum, and the yield was 74.2%, and the purity was 99.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com