Bridge construction method of full framing cast-in-place box girder

A technology for the construction of full support and bridges, which is applied in the direction of erecting/assembling bridges, bridges, bridge materials, etc., which can solve the problems of inconvenient construction process and achieve the effect of convenient preloading construction and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

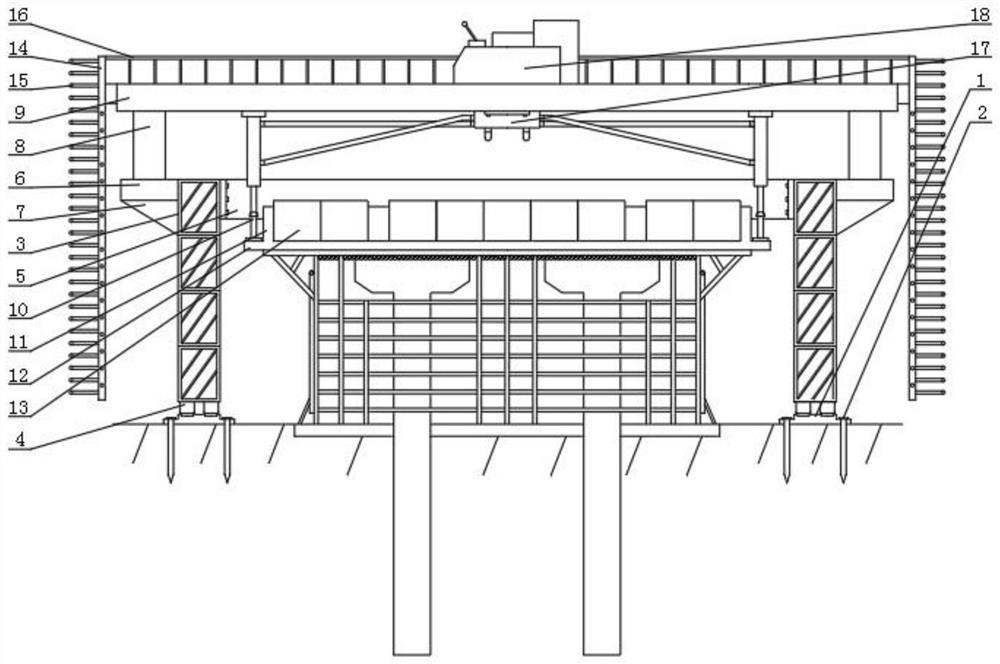

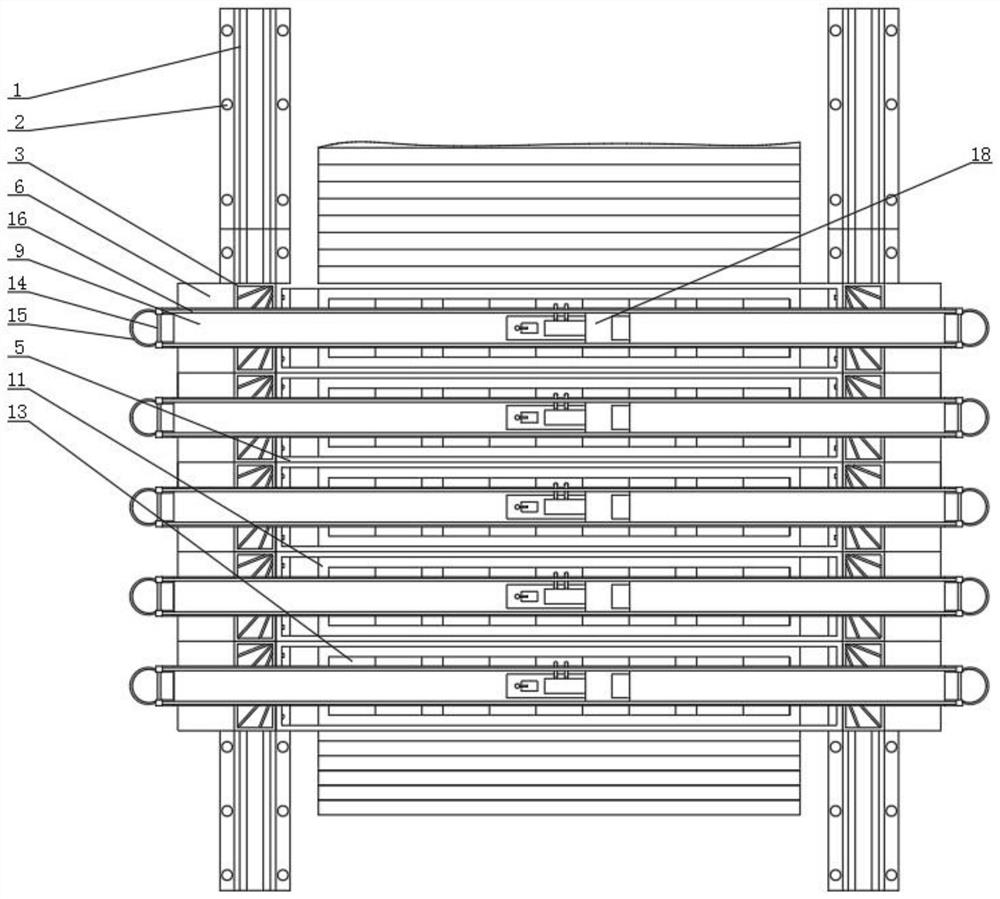

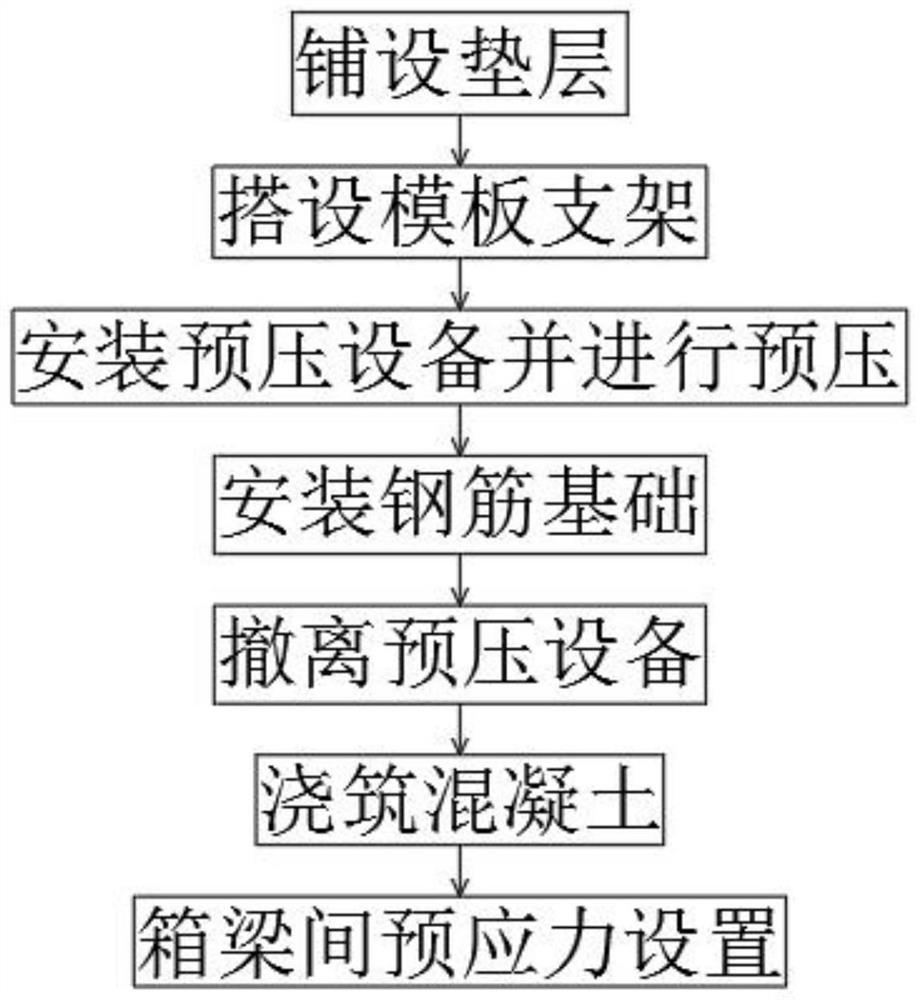

[0027] figure 1 , figure 2 and image 3 , the bridge construction method of cast-in-place box girder with full support includes the following steps:

[0028] Step 1: Lay the cushion, first clean and level the ground, and then pour 20cm of C20 plain concrete floor on the ground. The usefulness of laying the cushion mainly reflects the following points. First, it is mainly for fixing the formwork with expansion bolts The base of the bracket, secondly, when constructing the formwork support and preloading, avoid the settlement of the installation position of the formwork support;

[0029] Step 2: Set up the formwork support, put the wires on the floor to set up the formwork support. After the formwork support is set up, place the cross arm evenly on the formwork support. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com