Centrifugal pump capable of actively inhibiting cavitation as well as design method and mounting method of centrifugal pump

A technology of active suppression and centrifugal pumps, which is applied to parts, pumps, pump components, etc. of pumping devices for elastic fluids, and can solve the problems of limited bubble-like cavitation suppression effects, delayed cavitation, and limited suppression effects on the suction surface. problem, to achieve the effect of improving the effect of cavitation suppression and increasing the effect of connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

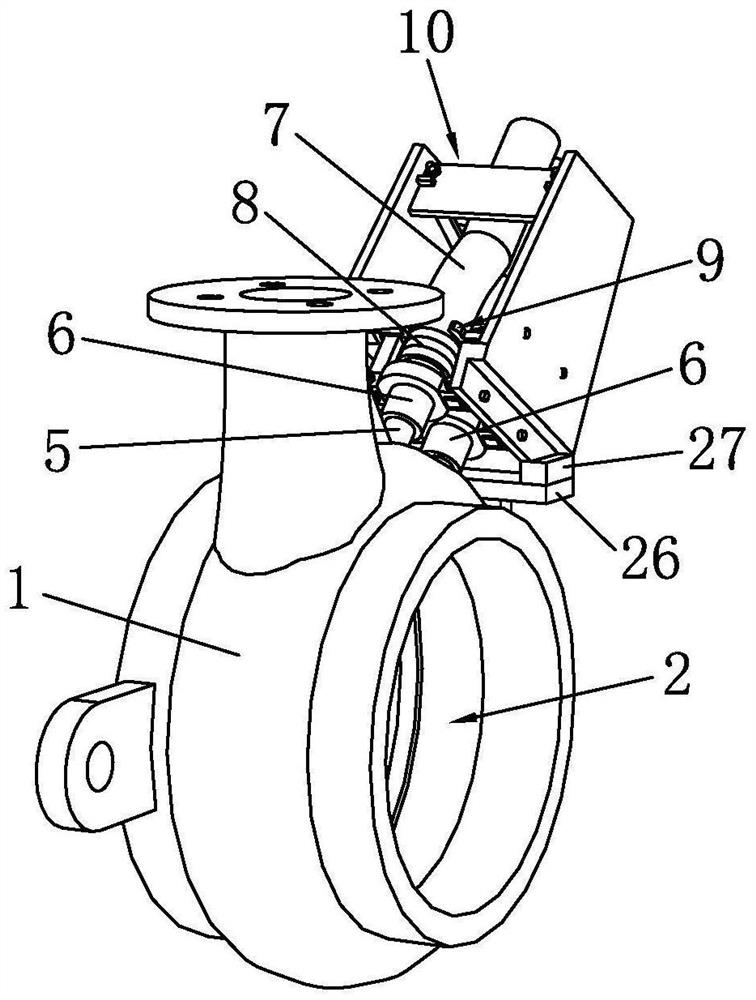

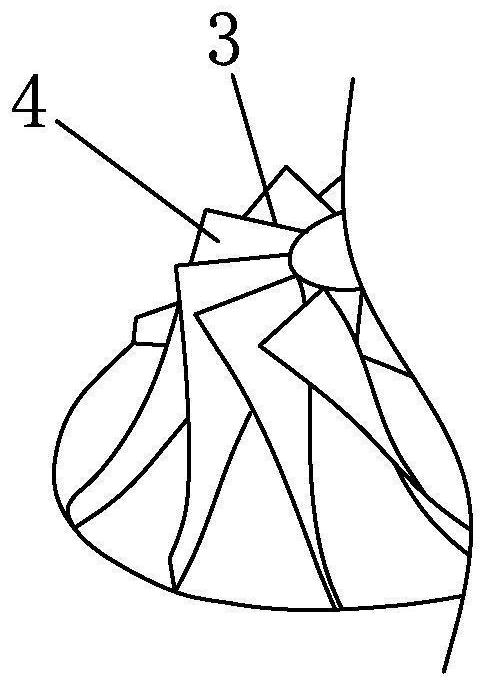

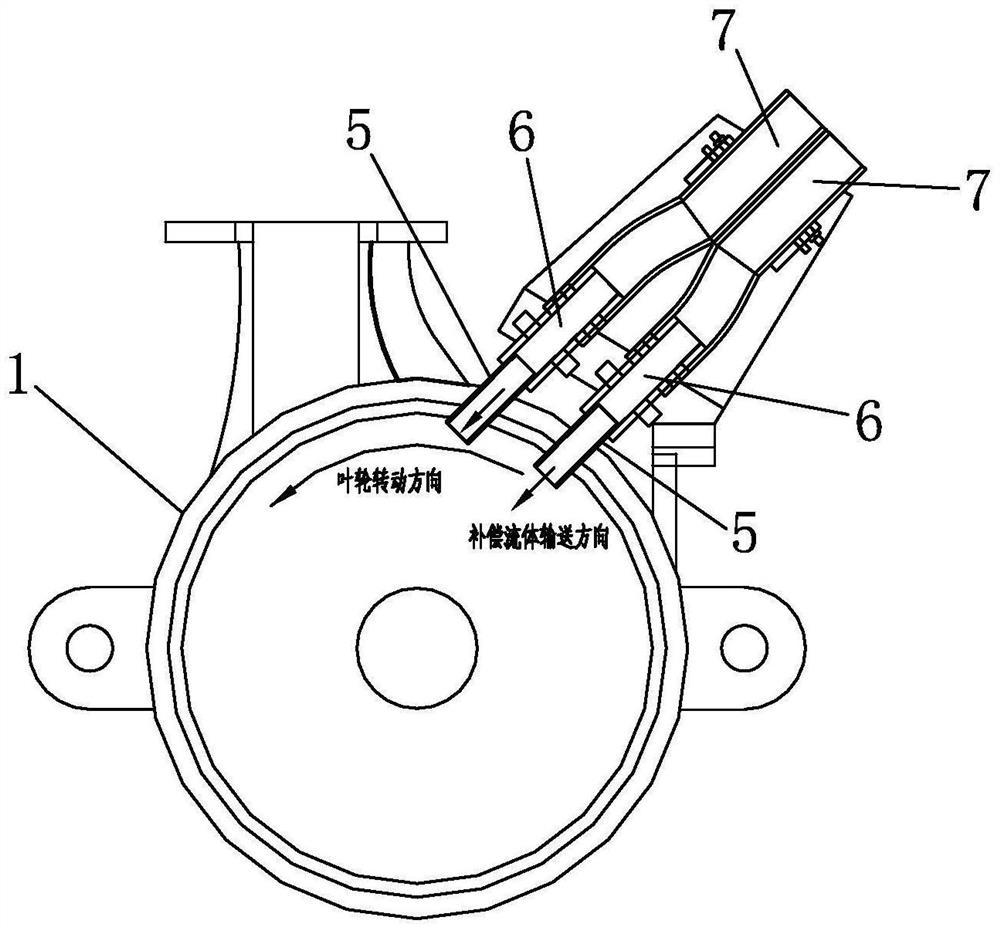

[0066] Such as Figure 1 to Figure 8 As shown, it is a centrifugal pump for actively suppressing cavitation according to the present invention, which includes a volute 1 and an impeller. A cavity 2 is provided inside the volute 1 , and the impeller is arranged in the cavity 2 . The present invention also includes a compensating pipe 5. The volute 1 is provided with a compensating hole. The compensating hole is correspondingly arranged at the low pressure area where the front edge 3 of the impeller and the suction surface 4 appear. The compensating tube 5 penetrates and is fixed in the compensating hole. The compensating tube 5 Send high-pressure compensation fluid to the low-pressure area, and the compensation fluid is sent along the rotation direction of the impeller. For example, when the impeller rotates counterclockwise, the compensation fluid is delivered at high pressure from right to left image 3 ). The present invention impacts the low-pressure area that occurs during ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com