Earthwork backfilling elevation measuring device suitable for large-size foundation pit or trench

An elevation measurement and large-scale technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of unsatisfactory measurement, inaccurate measurement results, interference of measurement accuracy, etc., and achieve strong practicability and market competitiveness. Structure The effect of simple design and guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

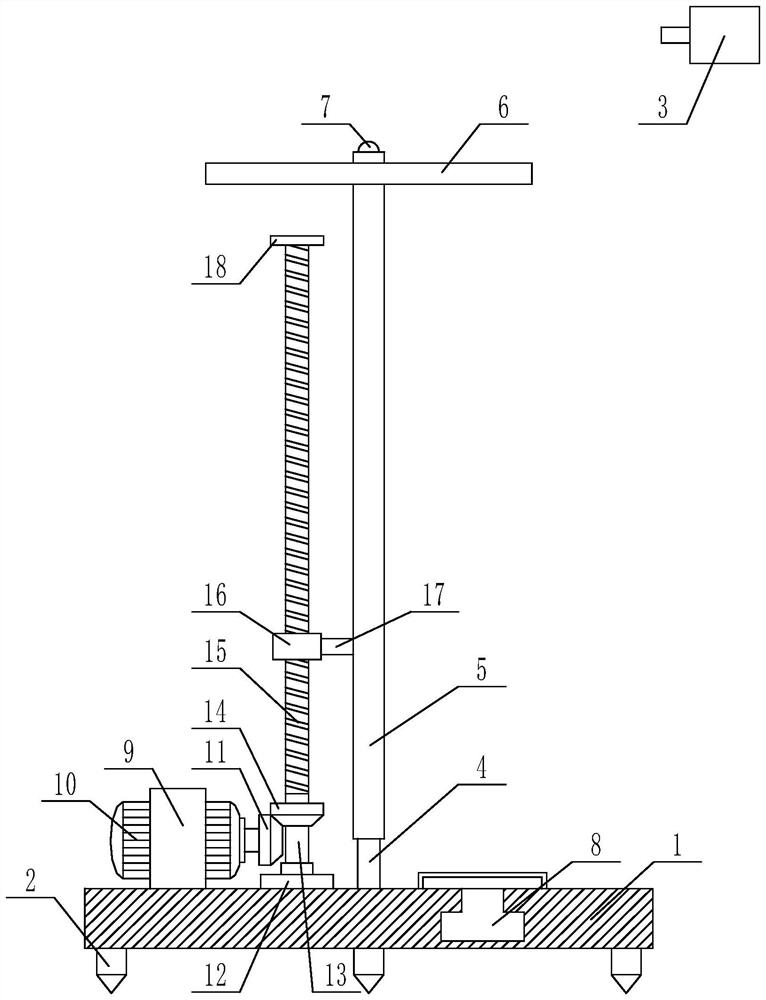

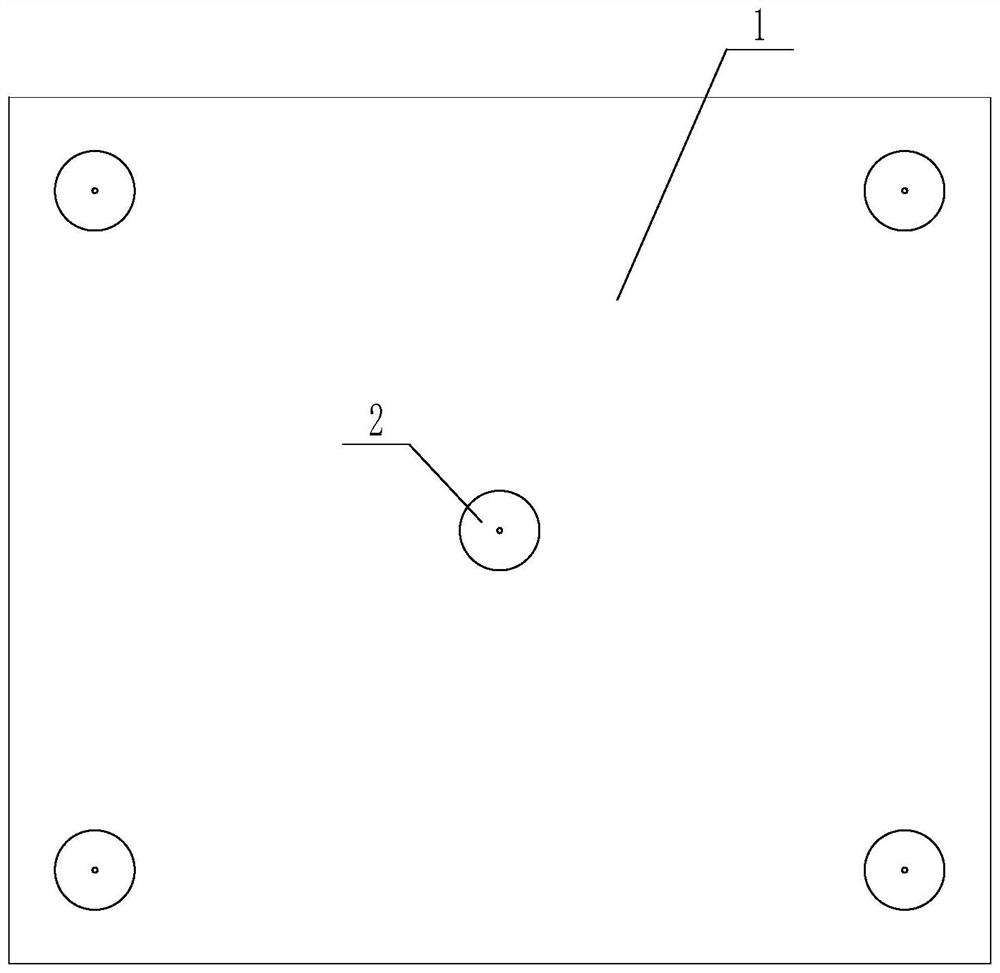

[0025] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-2 shown;

[0026] The invention of the present application is that the upper surface of the base is fixed with a column 4, the column is perpendicular to the upper surface of the base and the column is located at the center of the upper surface of the base, the column is covered with a sleeve 5, the A top plate 6 is fixedly installed on the casing, the column is perpendicular to the top plate, the top plate is close to the top of the column, and a photosensitive sensor 7 is fixedly installed on the upper end surface of the column, and the photosensitive sensor sends a signal to the control terminal through a wire;

[0027] The invention of the present application is also that the distance measuring sensor 8 is fixedly installed on the upper surface of the base, the distance measuring sensor is connected with the mobile terminal through the wireless communication ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com