Factory digital operation and maintenance system and operation and maintenance method

An operation and maintenance system and factory technology, applied in the field of digital industry, can solve problems such as digital operation and maintenance systems of few factories, and achieve the effect of efficient operation and maintenance management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048]In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

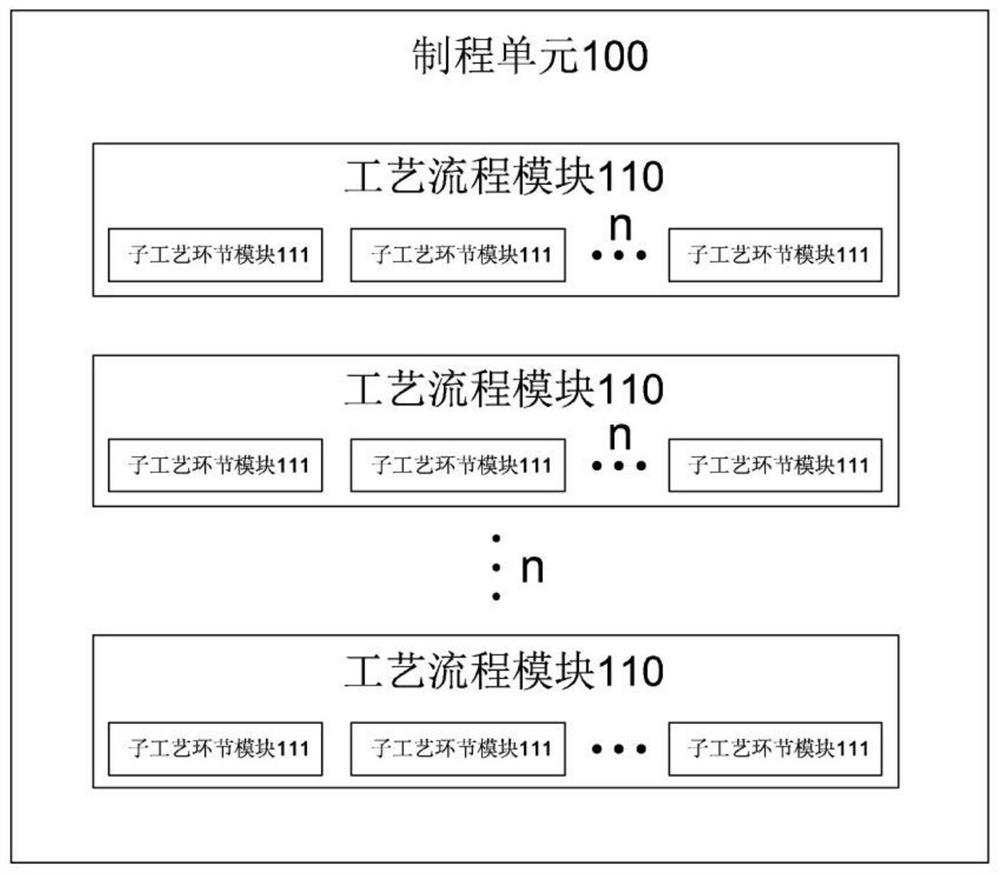

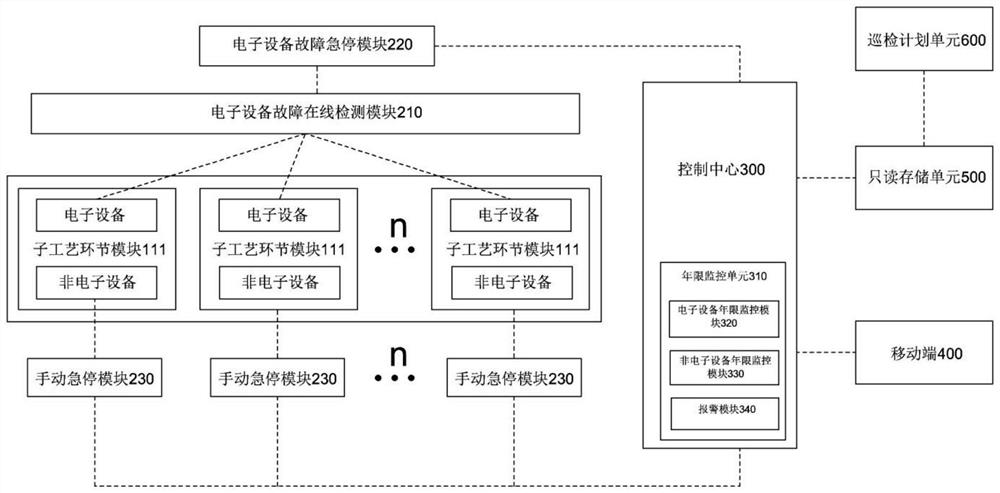

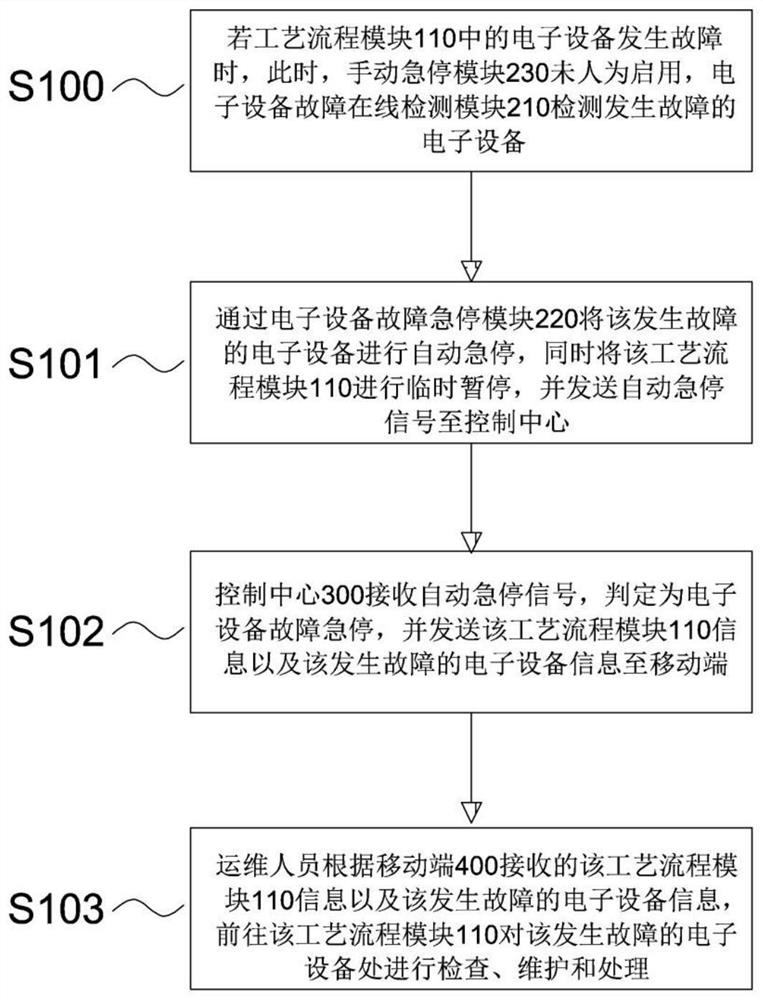

[0049] Such as Figure 1-Figure 2 As shown, a factory digital operation and maintenance system of the present invention includes a process unit 100, a fault detection unit 200, a control center 300, a mobile terminal 400, a read-only storage unit 500, and an inspection planning unit 600. The process unit 100 varies according to the factory The production line is divided into several process flow modules 110, and each process flow module 110 is divided into several sub-process link modules 111. The fault detection unit 200 includes an electronic equipment fault online detection module 210, an electronic equipment fault emergency stop module 220, and a manual emergency stop module 230. ;

[0050] Each process flow module 110 includes correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com