Visual identification, distance measurement and positioning method in port container automatic loading and unloading operation

A visual recognition, automatic loading and unloading technology, applied in character and pattern recognition, image analysis, image enhancement, etc., can solve the problems of limited information acquisition, inability to obtain the position of the spreader, and high cost, so as to improve the accuracy of distance measurement and reduce the difficulty of deployment And the effect of maintenance cost and quantity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be described in further detail below in conjunction with the accompanying drawings.

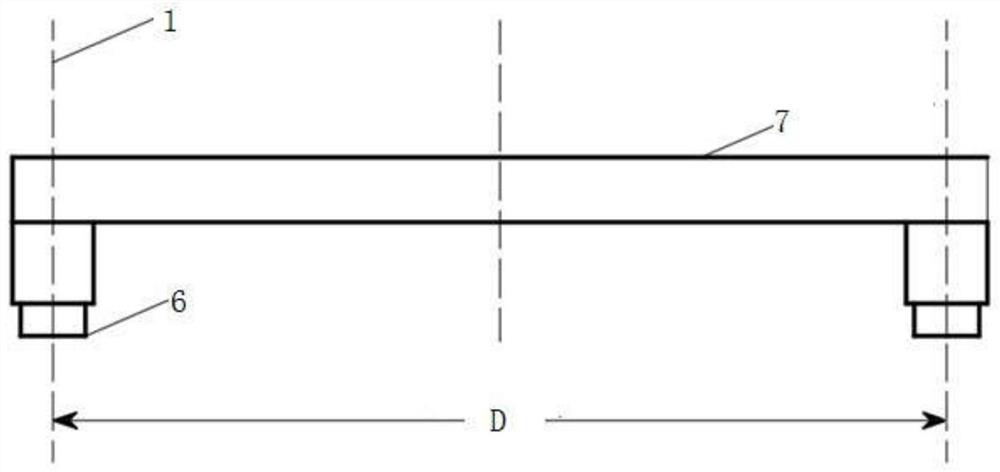

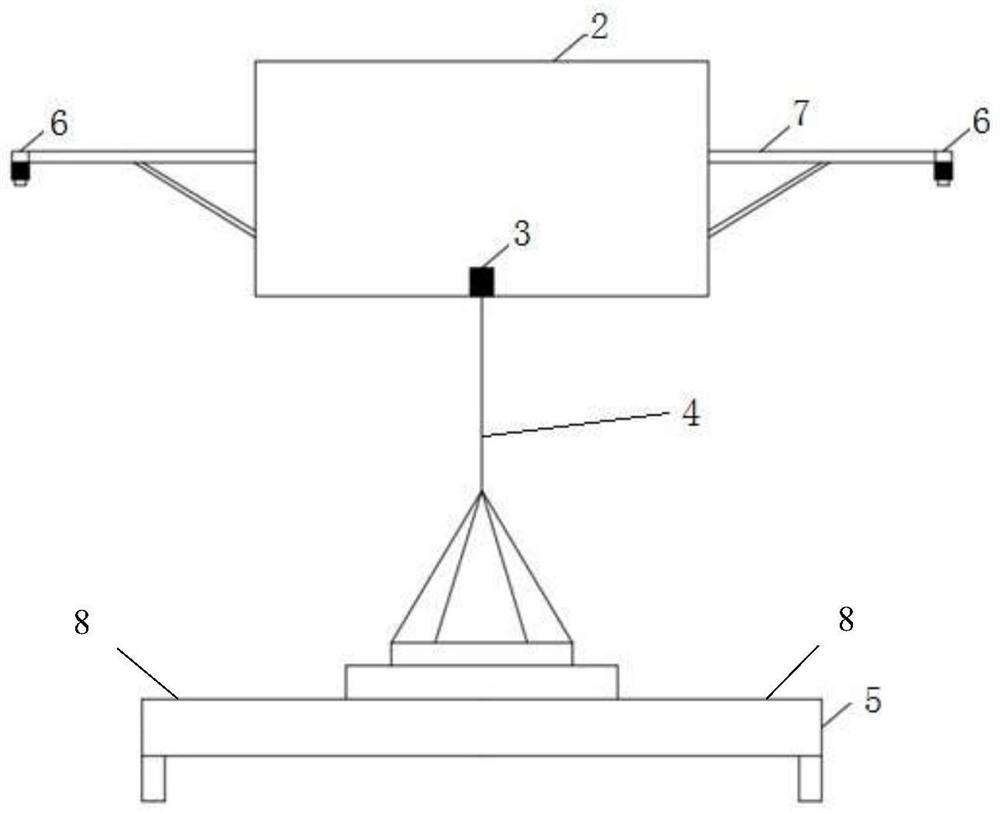

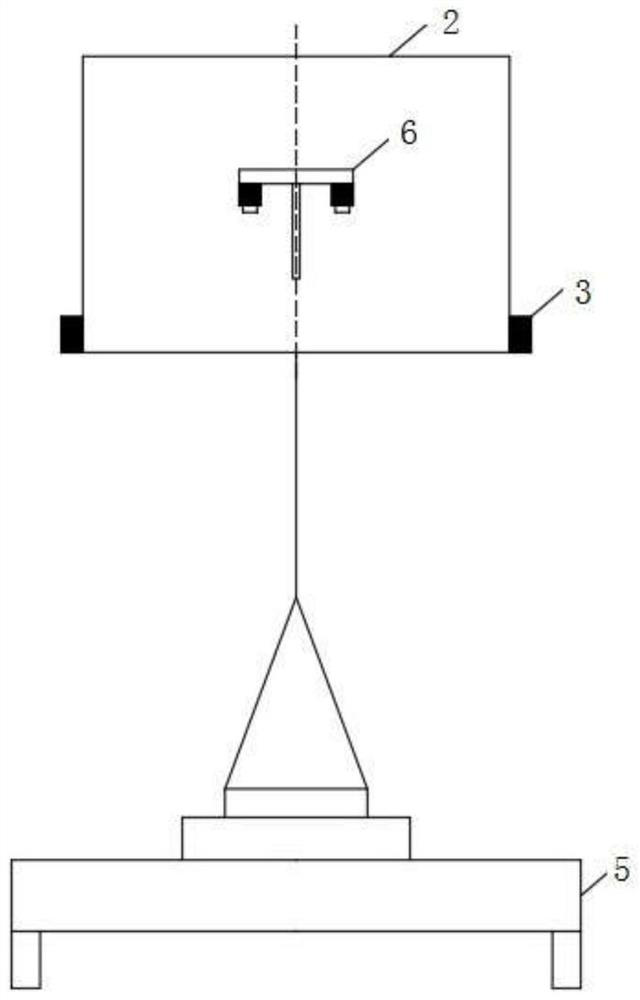

[0061] Such as Figure 1-3 As shown, the visual recognition, ranging and positioning method of the port container automatic loading and unloading operation of the present invention is based on the hardware foundation: there is a trolley 2 on the beam of the container bridge crane, and binocular cameras are respectively arranged on the front, rear and left and right sides of the trolley. system, the bottom of the trolley is equipped with a laser ranging sensor 3, and the bottom of the trolley is loaded with a spreader 5 through a sling 4, and the spreader is used to lift the target container to a designated position.

[0062] Based on the above-mentioned hardware system, the visual recognition, ranging and positioning method in the port container automatic loading and unloading operation of the present embodiment includes the following steps:

[0063] Step 1:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com