Automatic sealing cover of screening machine

A technology of automatic sealing and mechanical sealing cover, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of labor-consuming, low detection accuracy, delay in production, etc., to ensure normal operation, simple structure, and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

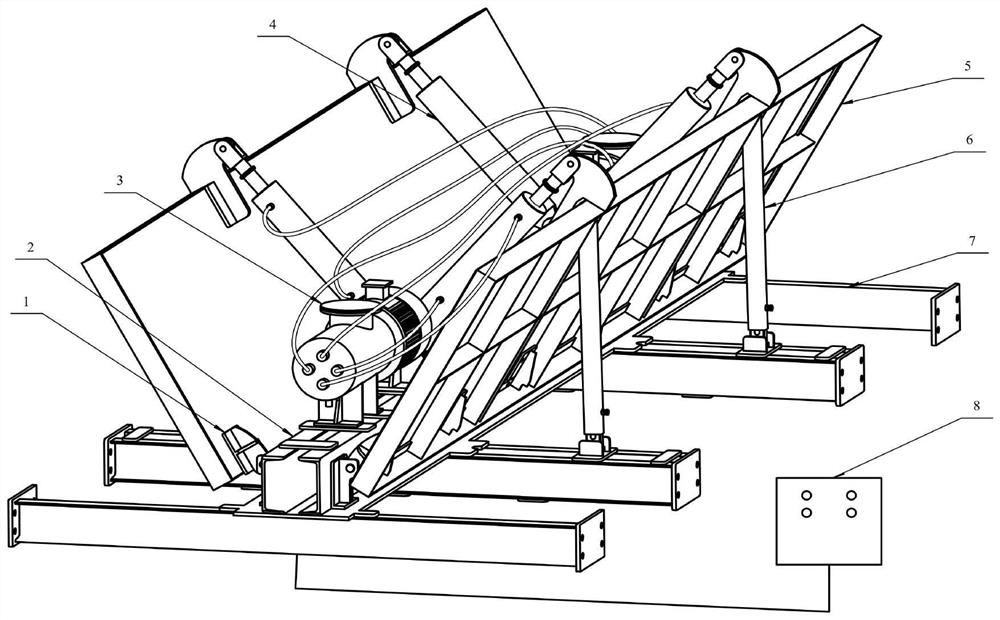

[0016] Combine below figure 1 The implementation of the present invention is further described:

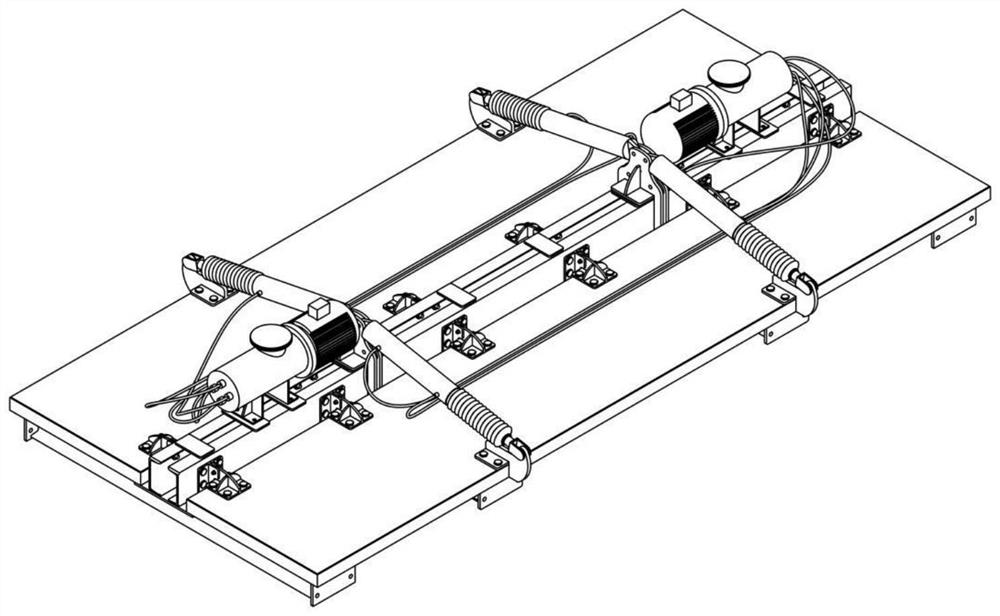

[0017] like figure 1 and figure 2 As shown, the automatic sealing cover of the screen machine of the present invention includes a cross beam 7, a longitudinal beam 2 combined with each other, a door body linked to the longitudinal beam 2 through a hinge 1, and the door body includes two left and right lids that are opened and closed through the hinge 1 5. The longitudinal beam 2 is equipped with a hydraulic station 3. The hydraulic station 3 pushes the cover body 5 in the door body through the hydraulic push rod 4 to perform a flipping opening and closing movement. The hydraulic station 3 is controlled by the electric control cabinet 8. After the cover body 5 is opened, the cover The insurance support device 6 linked below the body 5 moves with it, preventing the danger of the cover body falling due to the failure of the pressure of the hydraulic station 3 or the hydraulic push...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com