Raw material cleaning device for clinopodium polycephalum tablet production

A cleaning device and a technology for breaking blood flow tablets, which are applied in the directions of cleaning methods using liquids, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of cumbersome operations, inconvenient extraction of medicinal materials, etc., to save water resources, shorten the time Long cleaning time and cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

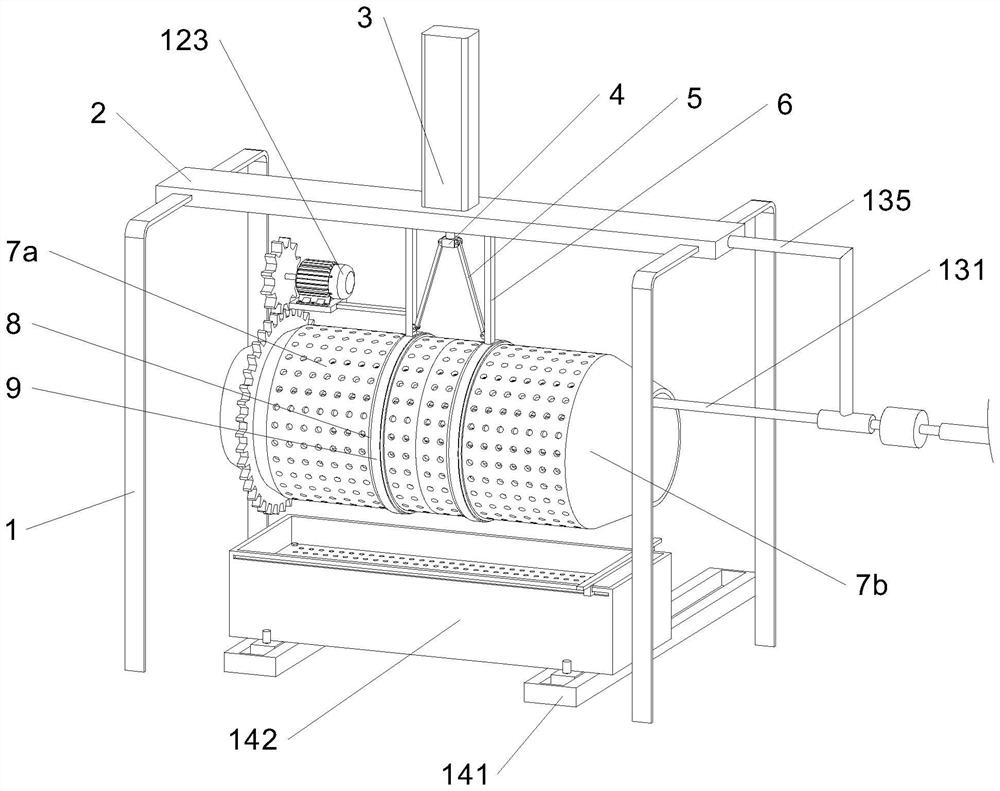

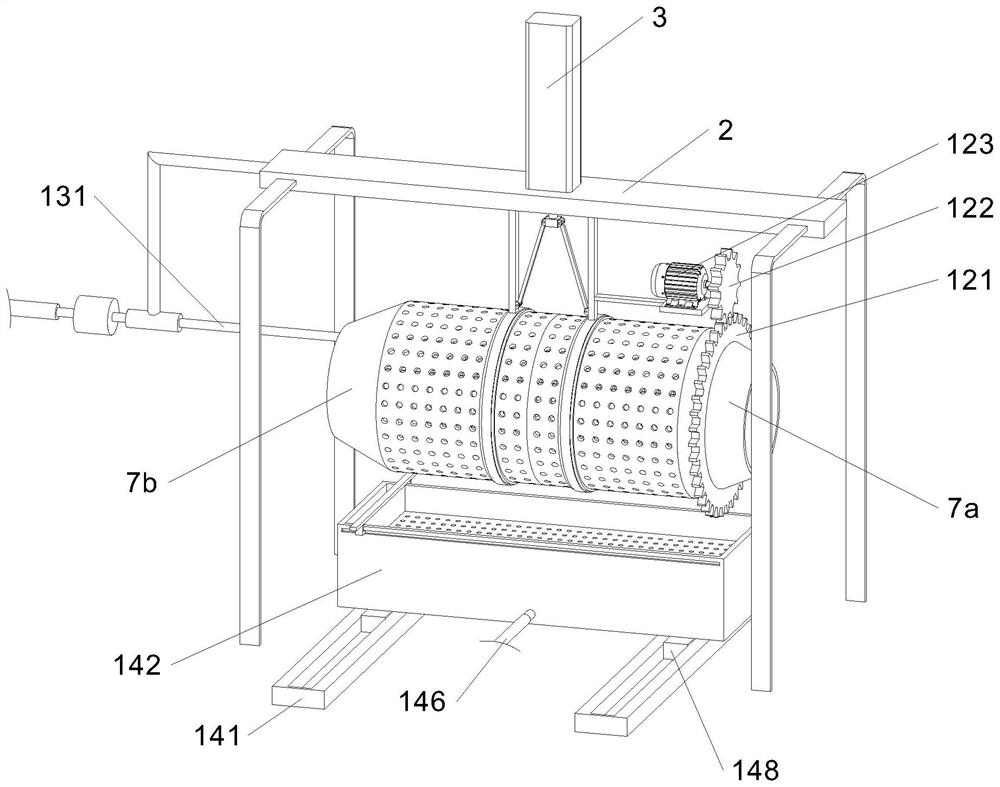

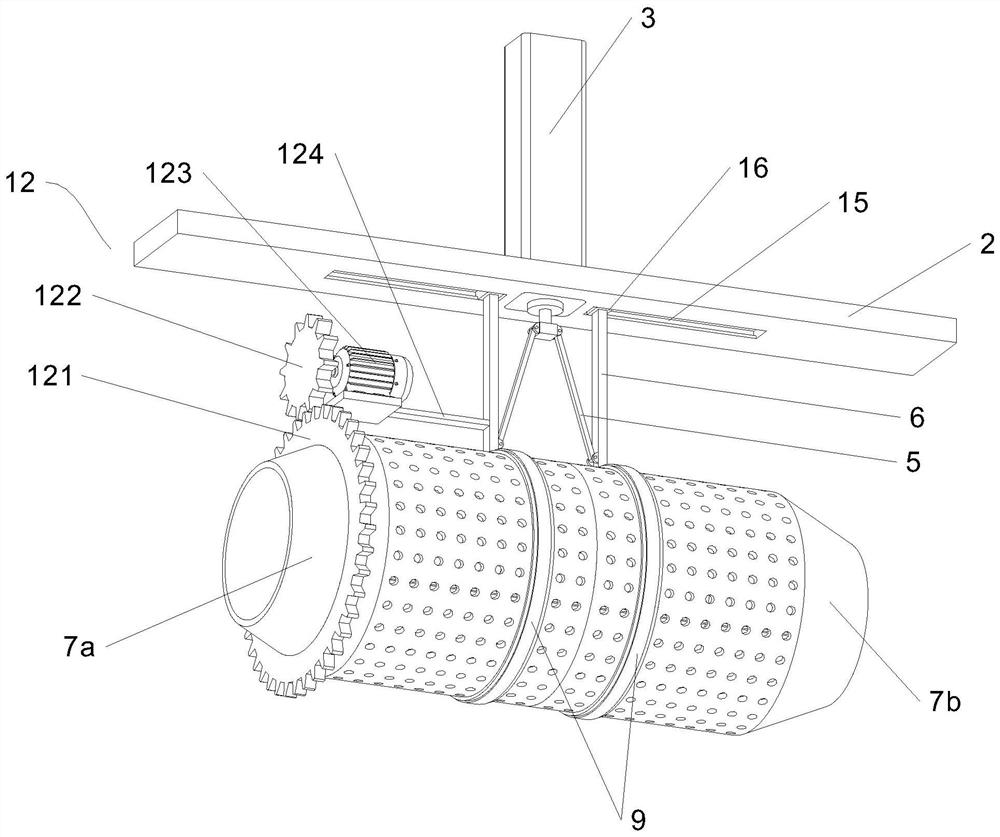

[0032] In this embodiment, as shown in Figures 1-6, a raw material cleaning device for the production of broken blood slices includes a support part, the support part includes a support plate 2, and a driving half cylinder 7a and a driven half cylinder are arranged below the support plate 2. The cylinder 7b, the inner ends of the driving half cylinder 7a and the driven half cylinder 7b are all fixed with a turning plate 17, and the setting of a plurality of turning plates 17 is conducive to the dispersion and turning of the raw materials, preventing the accumulation of raw materials, and improving the cleaning effect. 2 is equipped with an opening and closing mechanism for controlling the opening and closing of the driving half cylinder 7a and the driven half cylinder 7b; the opening and closing mechanism is connected with a power component 12 for controlling the rotation of the driving half cylinder 7a;

[0033] The opening and closing mechanism includes support rings 8 respec...

Embodiment 2

[0043] On the basis of Embodiment 1, a pre-cleaning mechanism 14 for preliminary cleaning of the raw materials is installed under the driving half cylinder 7a and the driven half cylinder 7b; specifically, the pre-cleaning mechanism 14 includes a The two support blocks 141 below the moving half cylinder 7b, the tops of the two support blocks 141 are slidingly connected with the same pre-cleaning box 142, the upper part of the inner wall of the pre-cleaning box 142 is fixed with a sieve plate 143 for placing raw materials, and the pre-cleaning box The lower part of the rear wall of 142 is communicated with and installed with a water outlet hose 146;

[0044] As mentioned above, lay the next batch of raw materials to be cleaned neatly on the sieve plate 143, move the pre-cleaning box 142 to the bottom of the cleaning cylinder, and rinse the raw materials on the sieve plate 143 with the water flowing out of the cleaning cylinder. Removing dirt and other impurities on the raw mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com