Annular finishing equipment for bamboo winding pipe gallery

A technology of form trimming and winding tubes, applied in mechanical equipment, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of bamboo strips tearing, easy to break, hard bamboo joints, etc., and achieve the effect of avoiding skew

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

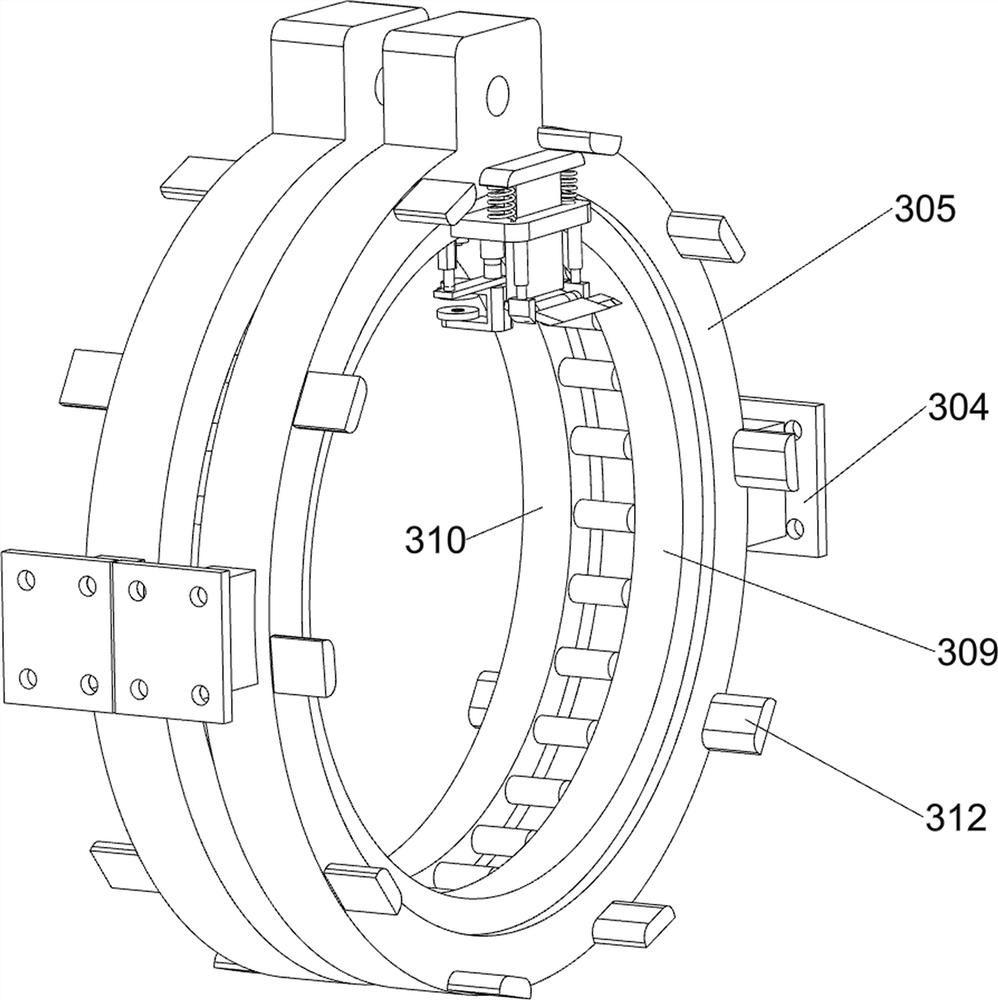

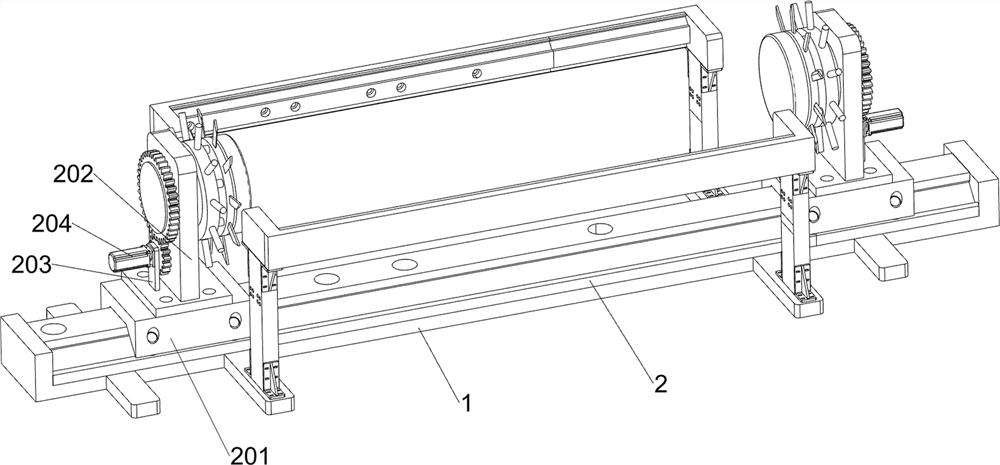

[0029] A kind of trimming equipment for bamboo winding pipe corridor ring form, according to Figure 1-2 As shown, it includes a fixed frame 1, a first guide rail 2, a cutting unit and a trimming unit; the upper surface of the fixed frame 1 is fixedly connected with the first guide rail 2; the first guide rail 2 is connected with a cutting unit; unit.

[0030] When working, the staff will fix the fixed frame 1 on the peripheral movable device, then move the fixed frame 1 to the desired use position, and then the staff will place the wrapped bamboo tube gallery on the first guide rail 2, and limit the bamboo pipe gallery through the cutting unit, and then, the trimming unit starts operation to polish the bamboo joints of the bamboo strips in the bamboo pipe gallery, and at the same time, multiple ring-wound bamboo strips Carry out the right position to avoid skewing of the bamboo strips. Then, the cutting unit starts to cut the left and right ends of the bamboo pipe gallery, a...

Embodiment 2

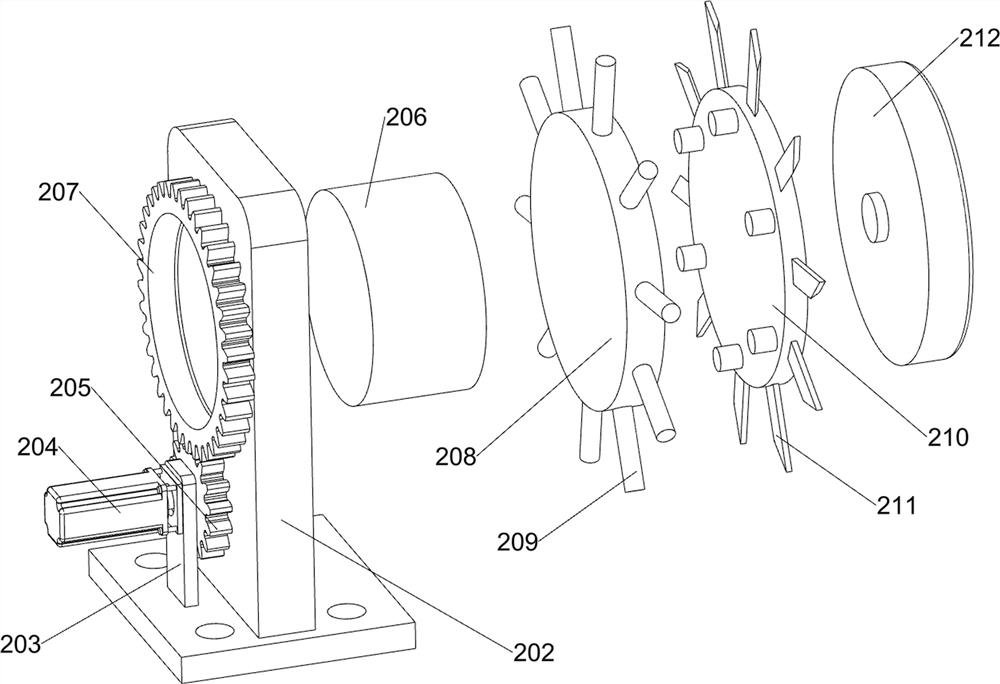

[0032] On the basis of Example 1, according to figure 1 with Figure 3-12 As shown, the cutting unit includes a first electric slider 201, a support frame 202, a first fixed plate 203, a first motor 204, a first spur gear 205, a cylinder 206, a gear ring 207, a disc 208, a first limiting Position rod 209, fixed disk 210, cutter 211 and limit disk 212; two first electric sliders 201 are slidably connected to the outer surface of the first guide rail 2; two first electric sliders 201 are fixedly connected with a Support frame 202; two support frames 202 opposite sides are fixedly connected with a first fixed plate 203; two first fixed plates 203 tops are equipped with a first motor 204; two first motor 204 output shafts are fixed A first spur gear 205 is connected; a cylinder 206 is rotatably connected to the upper parts of the two support frames 202; a toothed ring 207 is fixedly connected to the opposite side of the two cylinders 206; the two toothed rings 207 are connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com