Steering drive axle for forklift

A technology for steering drive axles and forklifts, which is applied in the field of forklifts, and can solve the problems of insufficient driving ability of forklifts, weak driving ability of forklifts, and single product functions, etc., and achieve the effects of compact structure, long service life, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

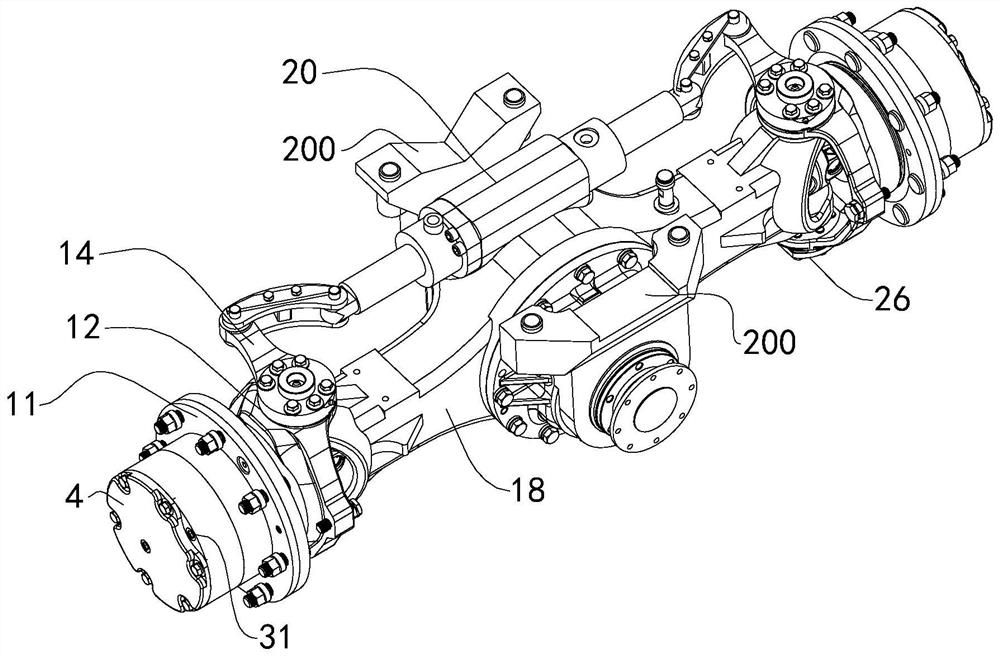

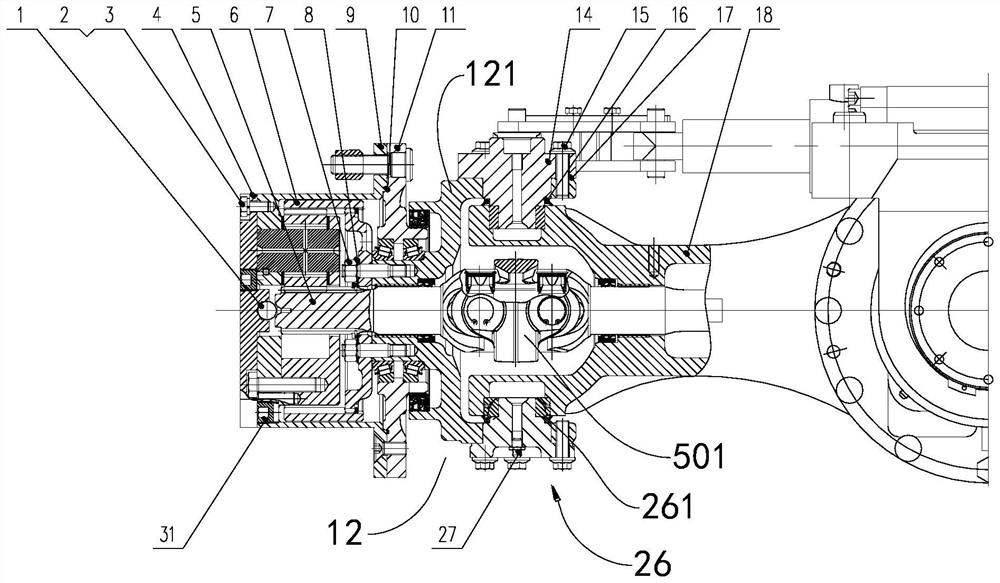

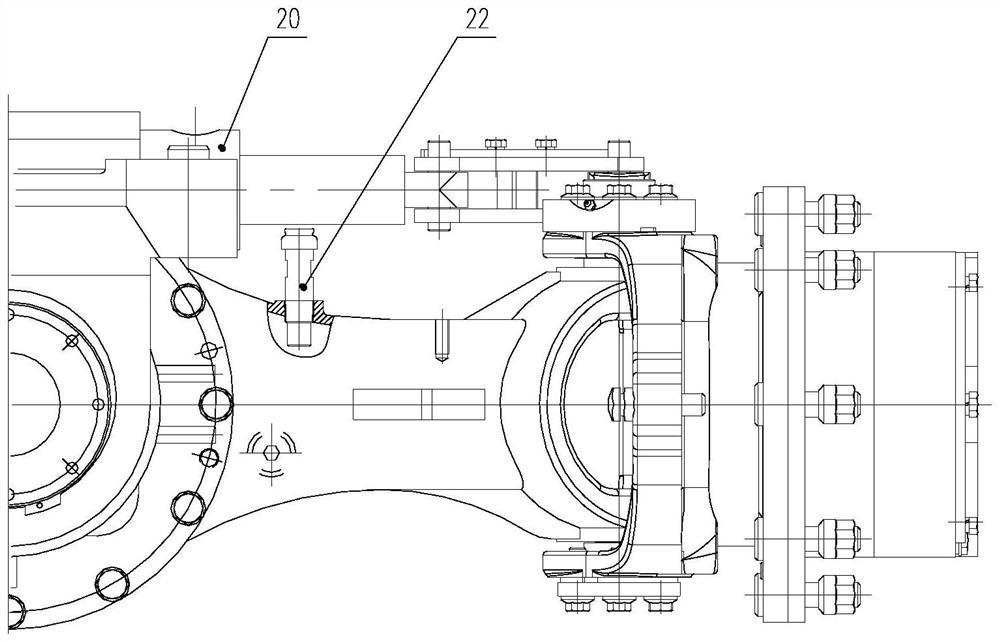

[0026] A steering drive axle for a forklift, refer to figure 1 and figure 2 As shown, it includes a final drive assembly 100 with a differential lock function, and an axle body assembly 18 . The final reducer assembly 100 is assembled in the rear part of the bridge body assembly 18 to output driving force to both ends of the bridge body assembly 18 . The middle part of the bridge body assembly 18 is equipped with a steering oil cylinder assembly 20, and the two ends of the bridge body assembly 18 are assembled with wheel hub assemblies 11 respectively. Tires can be assembled outside the wheel hub assembly 11 . A half-shaft assembly 5 is arranged between the hub assembly 11 and the final reducer assembly 100 , and the half-shaft assembly 5 realizes the steering and rotation of the steering wheel hub assembly 11 through the universal joint structure 501 . Through the axle shaft assembly, the wheel hub assembly 11 can be turned while moving forward.

[0027] The key point of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com