Automatic feeding system for facial mask packaging

An automatic feeding and masking technology, which is applied in the stacking of objects, unstacking of objects, transportation and packaging, etc., can solve the problems of increasing the space occupied by the feeding system, reduce the occupied space, improve the overall efficiency and high efficiency Stable automatic feeding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

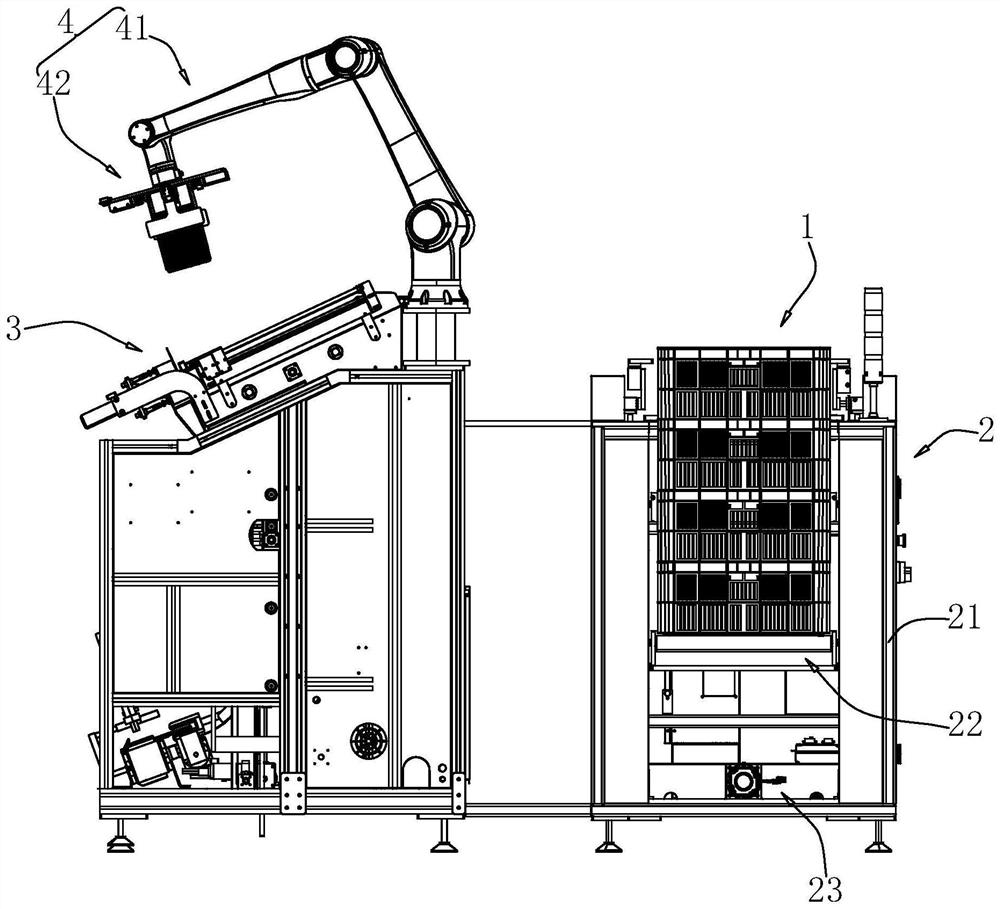

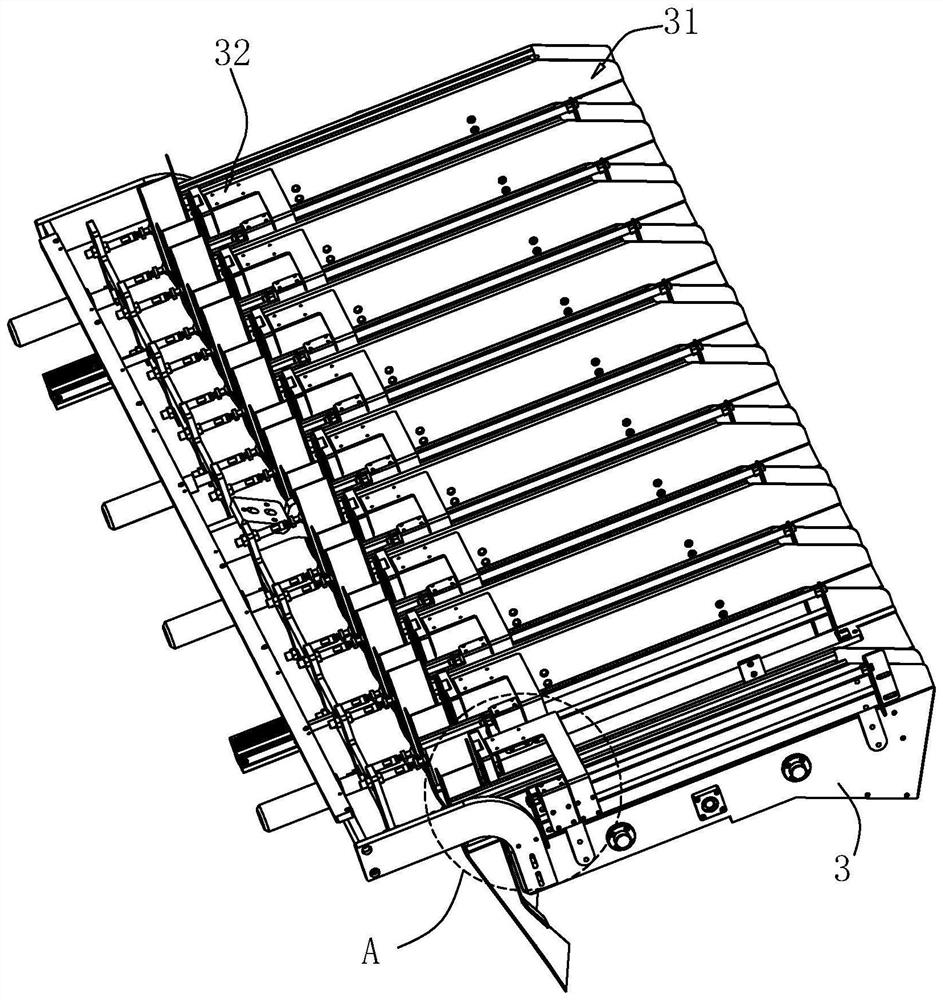

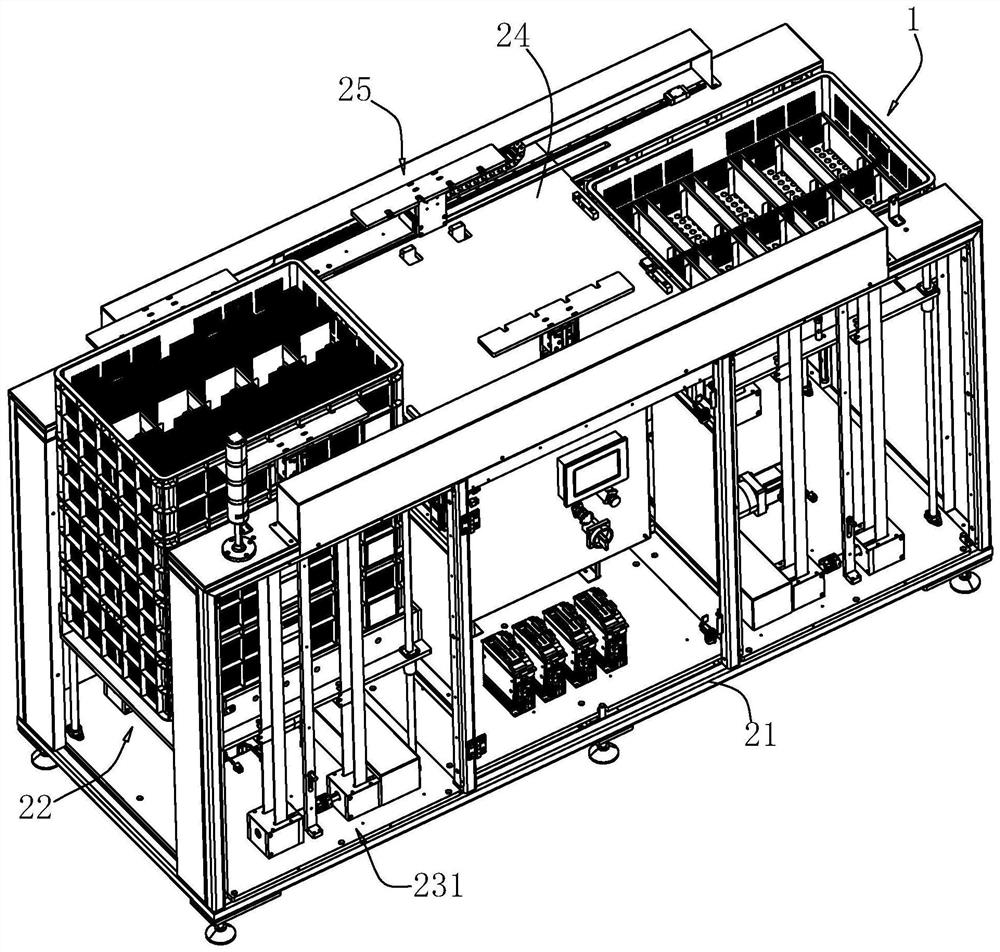

[0064] The embodiment of the present application discloses an automatic feeding system for mask packaging. refer to figure 1 and figure 2 , the automatic feeding system for mask packaging includes a material box 1, a material box storage and conveying device 2, a material placement rack 3 and a picking and loading device 4, wherein the material box 1 is used for stacking materials, and the material box is used for storing and conveying device 2 For storing and transporting the material box 1; the material placing frame 3 is on one side of the material storing and conveying device, and the material placing frame 3 is provided with an inclined placing groove 31 for placing the material for the subsequent mask packaging process. Correspondingly, the picking and loading device 4 is located in the area between the material placement rack 3 and the material box storage and conveying device 2, and is used to clamp and transfer the material stacked in the material box 1 in the mater...

Embodiment 2

[0112] The embodiment of the present application discloses an automatic feeding system for mask packaging. refer to Figure 16 and Figure 17, the difference between this embodiment and Embodiment 1 is that the structure of the driven adjustment assembly 442 is different; in this embodiment, the number of clamping mechanisms 42 is five, and the middle clamping mechanism 42 is fixedly connected with the main mounting plate 43 , is the fixed clamping unit 424, the two on one side of the fixed clamping unit 424 are the active clamping unit 425 and the driven clamping unit 426, and the driven adjusting components 442 have two groups and are symmetrically distributed in the fixed clamping unit 424 sides.

[0113] Specifically, the driven adjustment assembly 442 includes the deployment linkage structure 232 and the retraction linkage structure 232 . Wherein, when the active clamping unit 425 is driven away from the fixed clamping unit 424, the unfolding linkage structure 232 is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com