Extra-thick structural steel with high strength and good low-temperature toughness and production method thereof

A low-temperature toughness and production method technology, which is applied in the field of steel rolling, can solve problems such as poor low-temperature toughness of high-strength and extra-thick structural steel plates, and achieve high strength, reduce energy consumption, and inhibit grain growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

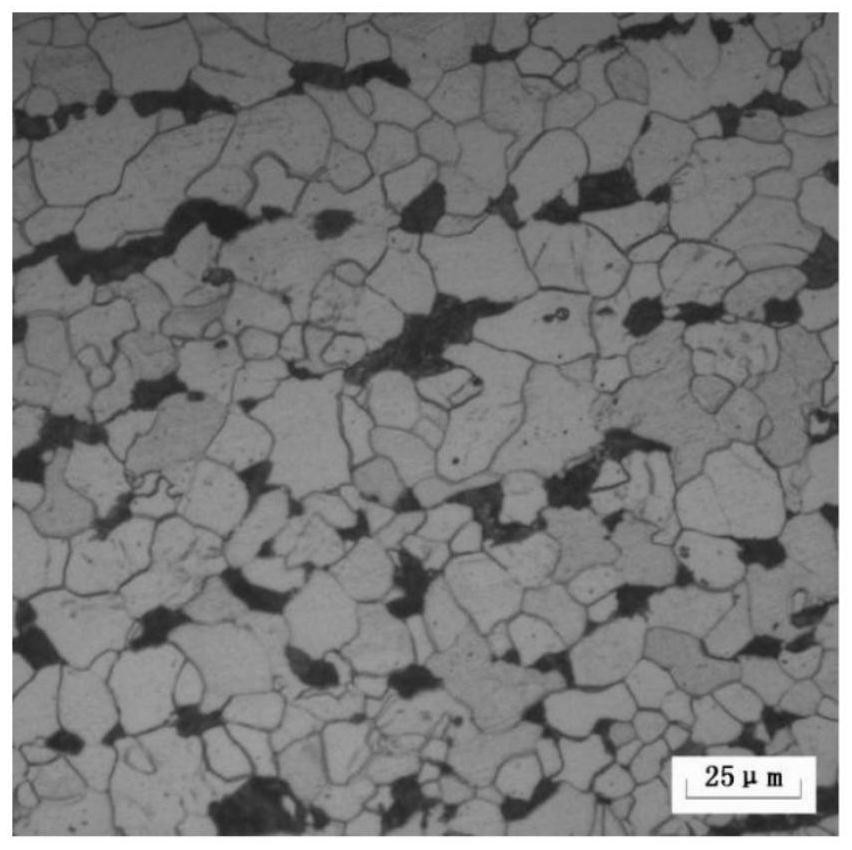

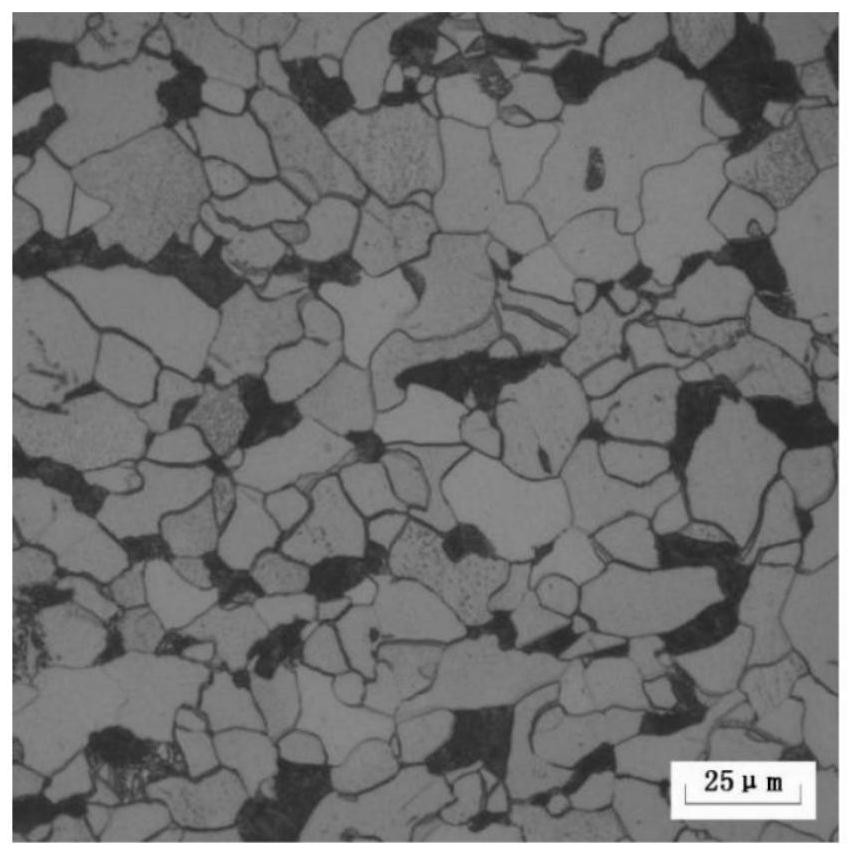

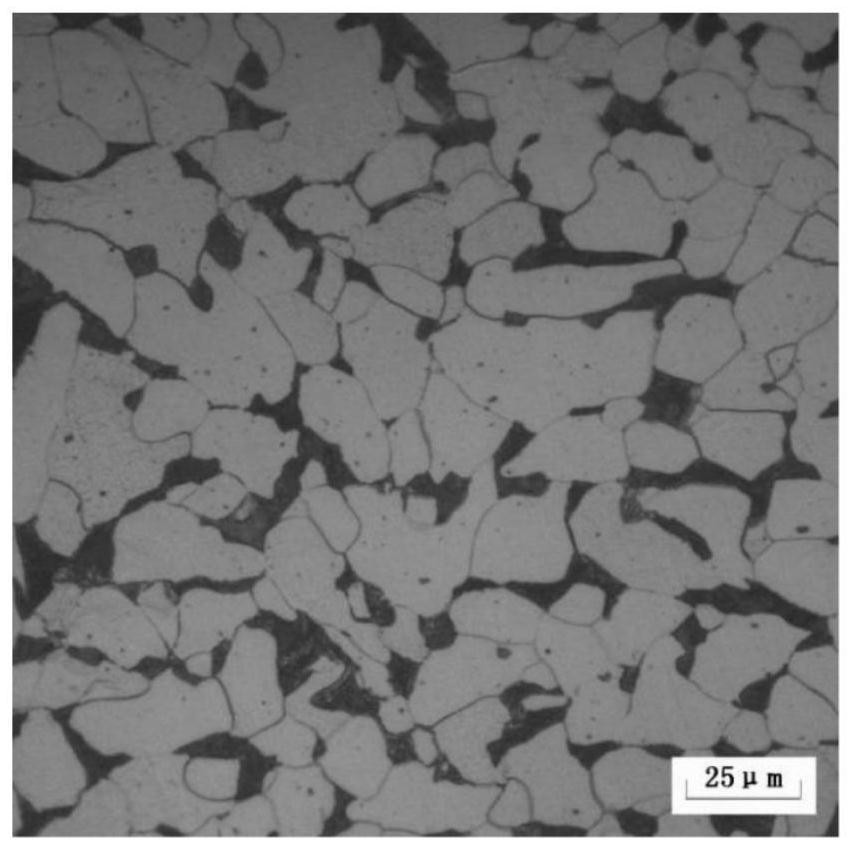

Image

Examples

Embodiment

[0084] An extra-thick structural steel with high strength and good low-temperature toughness, prepared by the following method:

[0085] (1) Obtain a slab with a thickness of 200-400mm and a width of 1800-2400mm, in terms of mass fraction, the chemical composition of the slab is:

[0086] C: ≤0.12%, Si: 0.20~0.50%, Mn: 1.00~2.00%, P: ≤0.010%, S: ≤0.003%, Al: 0.020~0.050%, Cu: ≤1.00%, Cr: ≤1.00% , Ni≤1.00%, Mo≤0.80%, and the balance is Fe and unavoidable impurities.

[0087] (2) Heating before slab rolling: the heating temperature is 1120-1170°C, and the heating time is 200min-400min.

[0088] (3) Rough rolling: 9 to 14 passes are adopted, the maximum deformation rate of a single pass is ≥15%, the rough rolling start temperature is 1050 to 1100°C, the rough rolling end temperature is 950 to 1030°C, and the intermediate billet after the rough rolling is finished Thickness ≥ 2t, t is the thickness of the extra-thick structural steel.

[0089] (4) Finish rolling: The start temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com