Method for realizing three-dimensional space stress or strain path by using conventional triaxial apparatus

A technology of three-dimensional space and stress path, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of slow improvement of true triaxial instrument, expand test range and functional modules, reduce test cost, increase test Effects of function and scope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

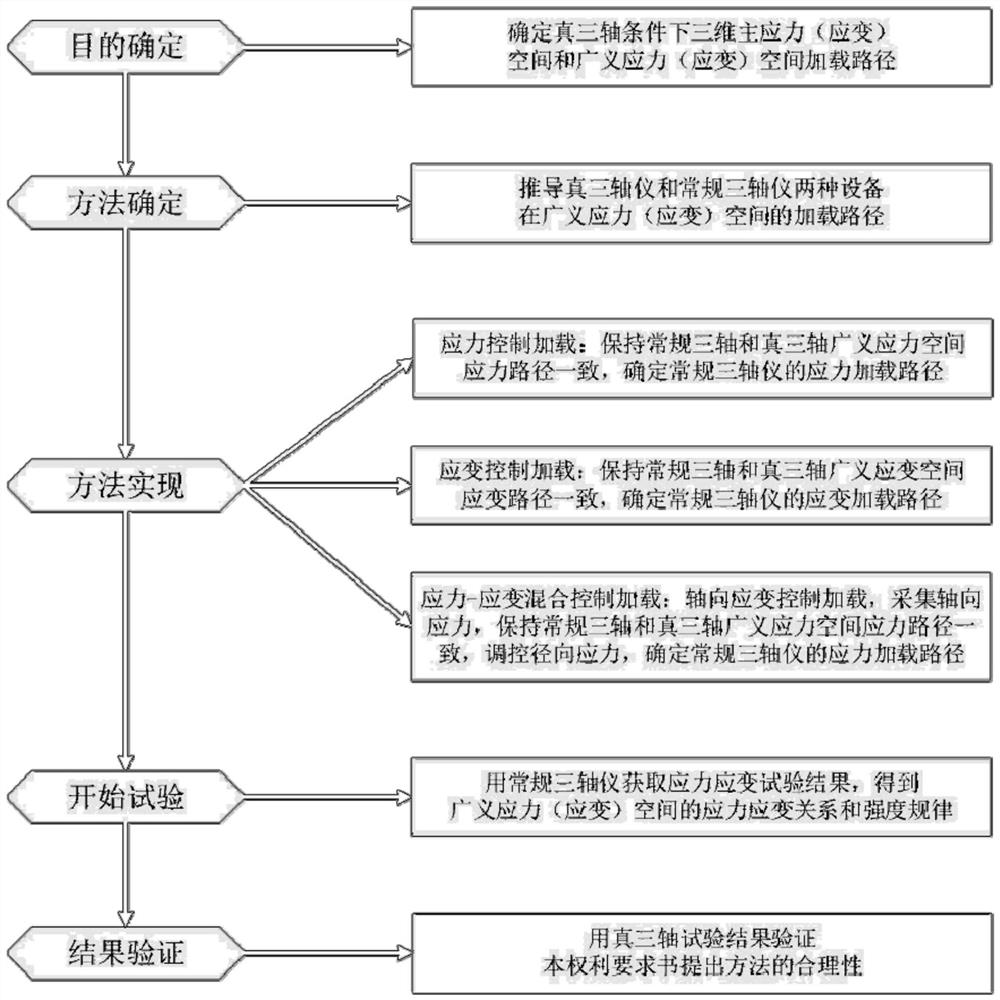

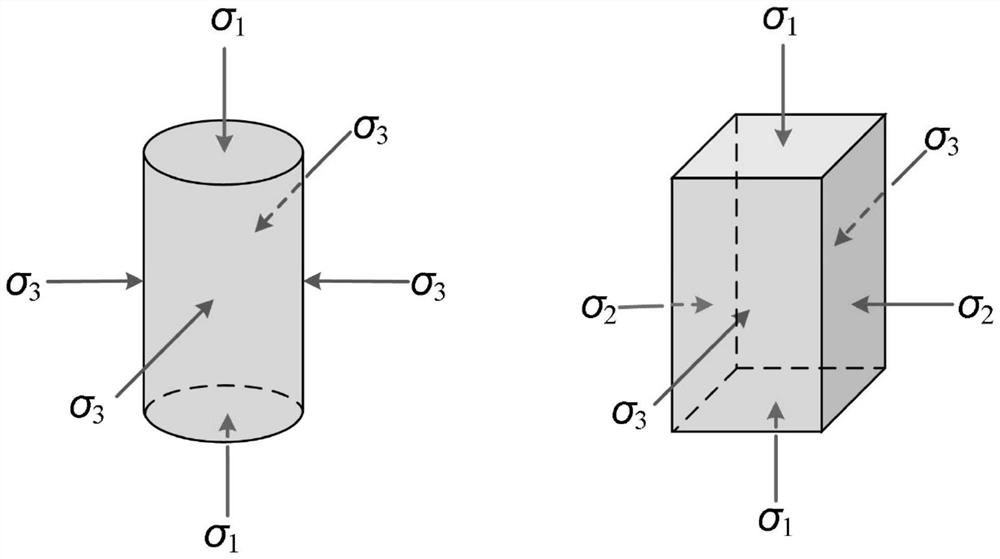

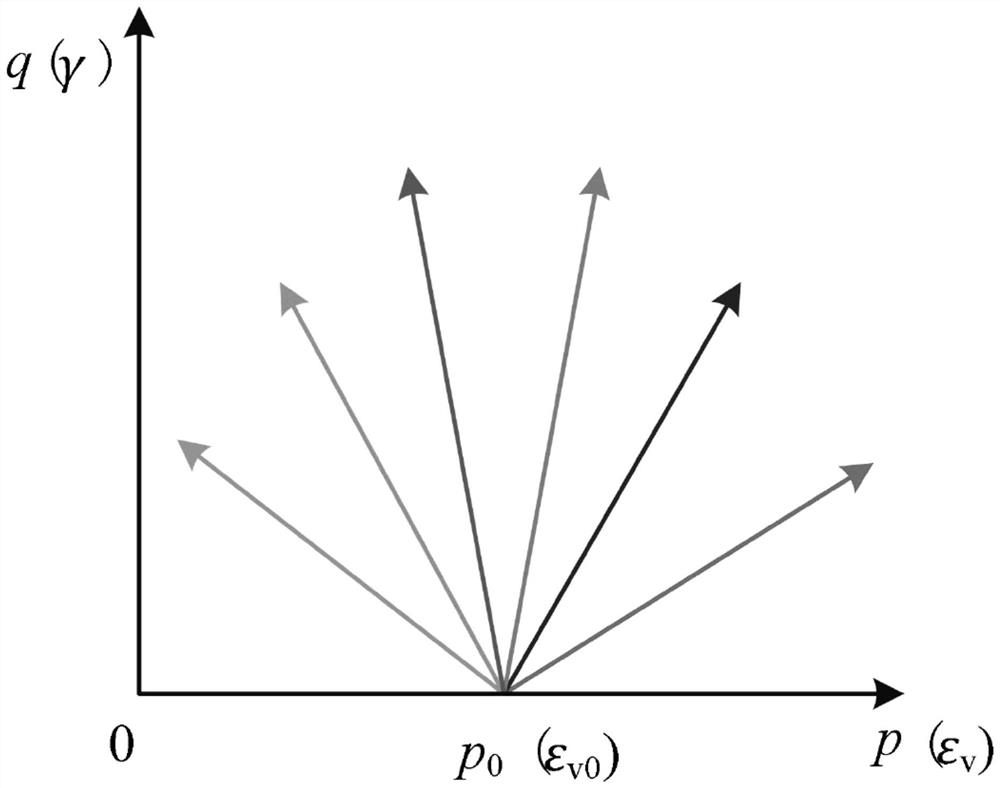

[0155] Example: such as figure 1 As shown, a method for realizing three-dimensional stress or strain path using a conventional triaxial instrument, which includes the following steps: determining the test program under true triaxial conditions in three-dimensional principal stress, principal strain space, and generalized stress, strain space the loading path of the generalized triaxial instrument and the conventional triaxial instrument in the generalized stress or strain space; control the loading method of the conventional triaxial instrument so that the loading path of the conventional triaxial instrument in the generalized stress and strain space The loading path of the axial instrument in the generalized stress and strain space is consistent; the conventional triaxial instrument is used to obtain the stress-strain test results, and the mechanical parameters of the generalized stress or strain space are obtained.

[0156] Among them: the above-mentioned loading methods for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com