Method for analyzing sources of large inclusions in heavy rail steel

An analysis method and technology of inclusions, applied in the direction of analyzing materials, using wave/particle radiation for material analysis, measuring devices, etc., can solve the problem of imperfect and inaccurate judgment of the source of large inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

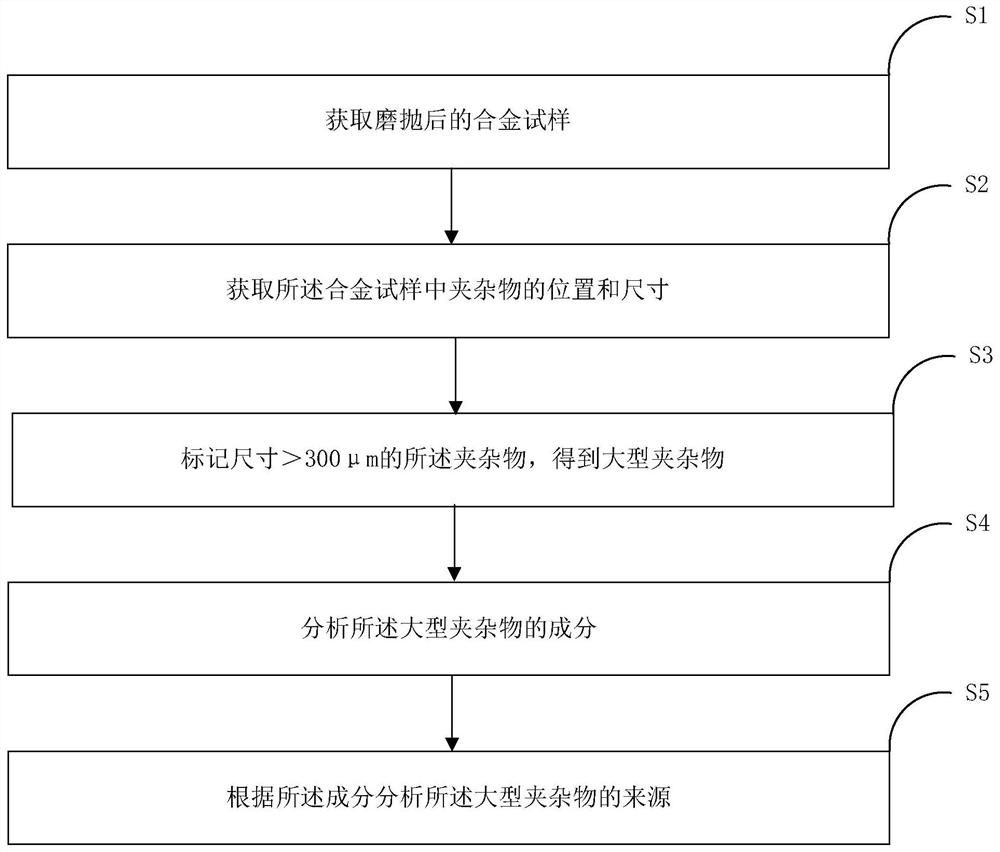

[0114] This embodiment provides a method for analyzing the source of large inclusions in heavy rail steel, including the following steps:

[0115] S1. Obtain the alloy sample after grinding and polishing.

[0116] S2. Using a microscope to obtain the position and size of the inclusions in the alloy sample.

[0117] S3. Using an indenter to mark the inclusions with a size >300 μm to obtain large inclusions.

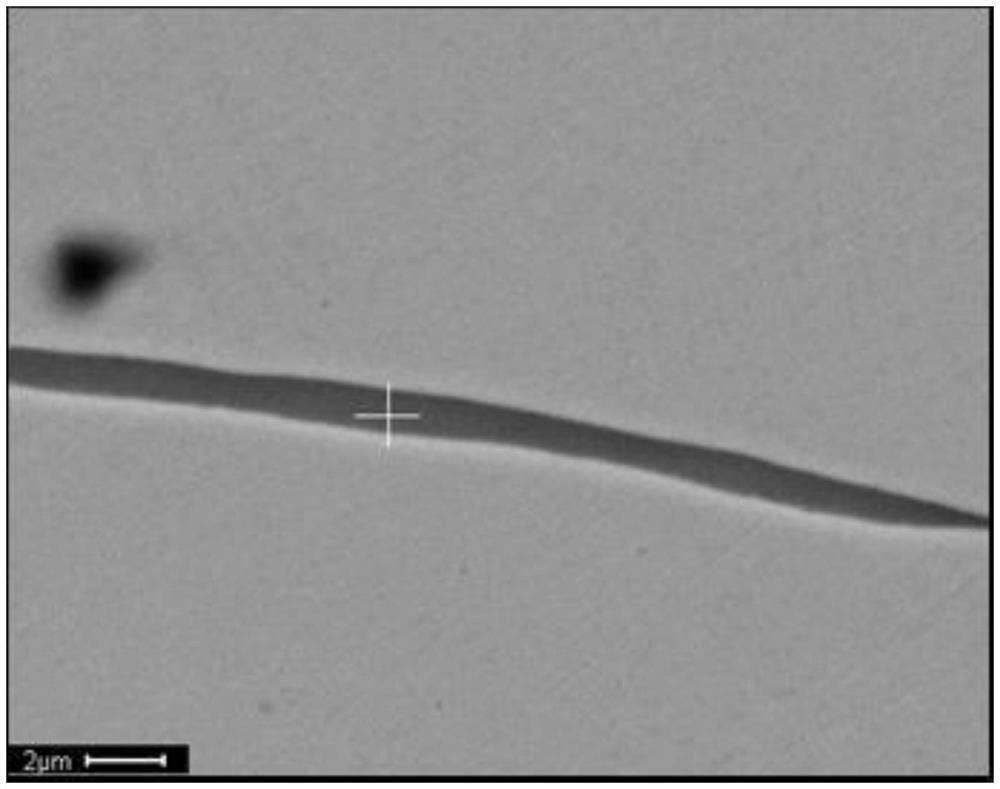

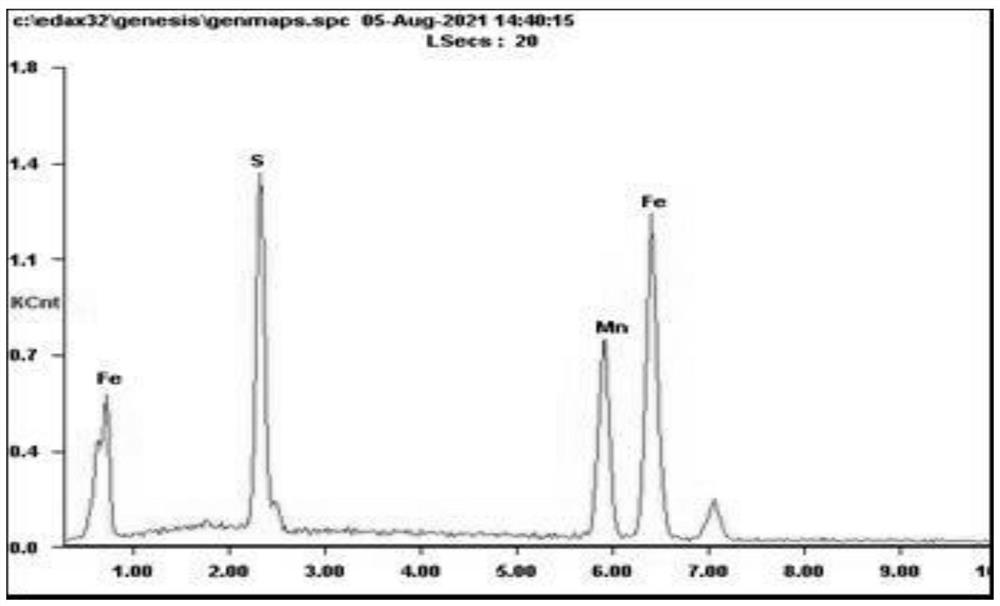

[0118] S4. Using scanning electron microscope and energy spectrum analyzer to analyze the composition of the large inclusions, the scanning electron microscope picture is shown in figure 2 , the energy spectrum analysis diagram sees image 3 .

[0119] S4.1. Analyzing the overall morphology of the large inclusions.

[0120] S4.1.1, by figure 2 It can be seen that the large inclusions are strip-shaped, consistent in color, and the ends are smooth, so it is judged that the large inclusions are sulfides. image 3 It can be seen that the sulfide is manganese sulfide.

Embodiment 2

[0122] S1. Obtain the alloy sample after grinding and polishing.

[0123] S2. Using a microscope to obtain the position and size of the inclusions in the alloy sample.

[0124] S3. Using an indenter to mark the inclusions with a size >300 μm to obtain large inclusions.

[0125] S4. Using scanning electron microscope and energy spectrum analyzer to analyze the composition of the large inclusions, the scanning electron microscope picture is shown in Figure 4 , the energy spectrum analysis diagram of steel slag is shown in Figure 5 , see the composition diagram of steel slag Image 6 , the energy spectrum analysis diagram of refractory material is shown in Figure 7 , see the refractory composition diagram Figure 8 .

[0126] S4.1. Analyzing the overall morphology of the large inclusions.

[0127] S4.1.2, by Figure 4 It can be seen that the large inclusions are irregular strips with clear boundaries and sharp edges and corners. It is judged that the large inclusions ar...

Embodiment 3

[0136] S1. Obtain the alloy sample after grinding and polishing.

[0137] S2. Using a microscope to obtain the position and size of the inclusions in the alloy sample.

[0138] S3. Using an indenter to mark the inclusions with a size >300 μm to obtain large inclusions.

[0139] S4. Using scanning electron microscope and energy spectrum analyzer to analyze the composition of the large inclusions, the scanning electron microscope picture is shown in Figure 9 , the energy spectrum analysis diagram of steel slag is shown in Figure 10 , see the composition diagram of steel slag Figure 11 , the energy spectrum analysis diagram of refractory material is shown in Figure 12 , see the refractory composition diagram Figure 13 .

[0140] S4.1. Analyzing the overall morphology of the large inclusions.

[0141] S4.1.2, by Figure 9 It can be seen that the large inclusions are irregular strips with clear boundaries and sharp edges and corners. It is judged that the large inclusio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com